Automatic cleaning technology for plastic double-helix link

A self-cleaning, double-helix technology, applied in the direction of rotating equipment cleaning, cleaning heat transfer devices, heat exchange equipment, etc., can solve the problem that plastic spiral bonds cannot automatically clean hard dirt and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

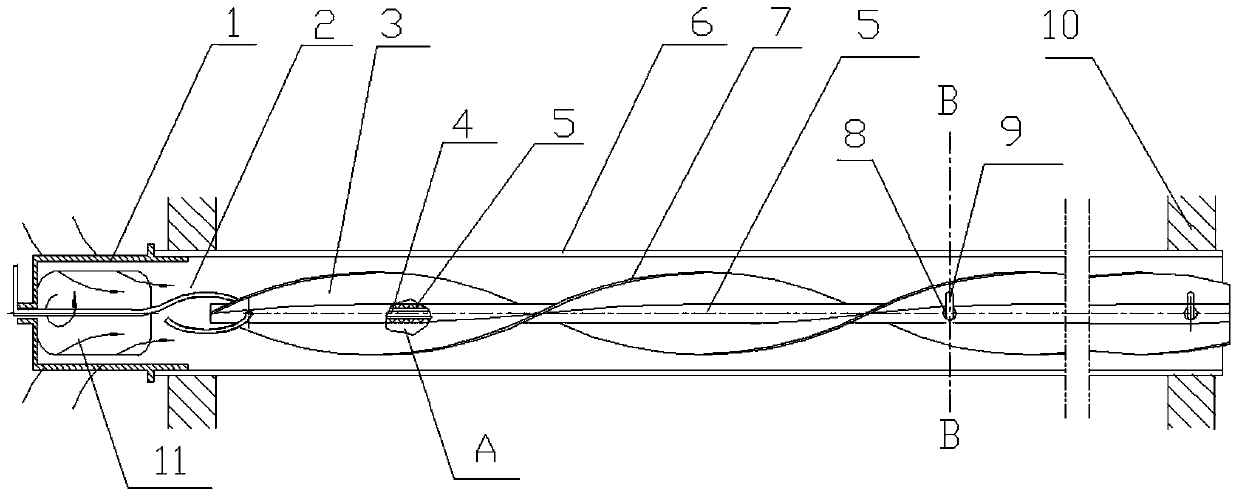

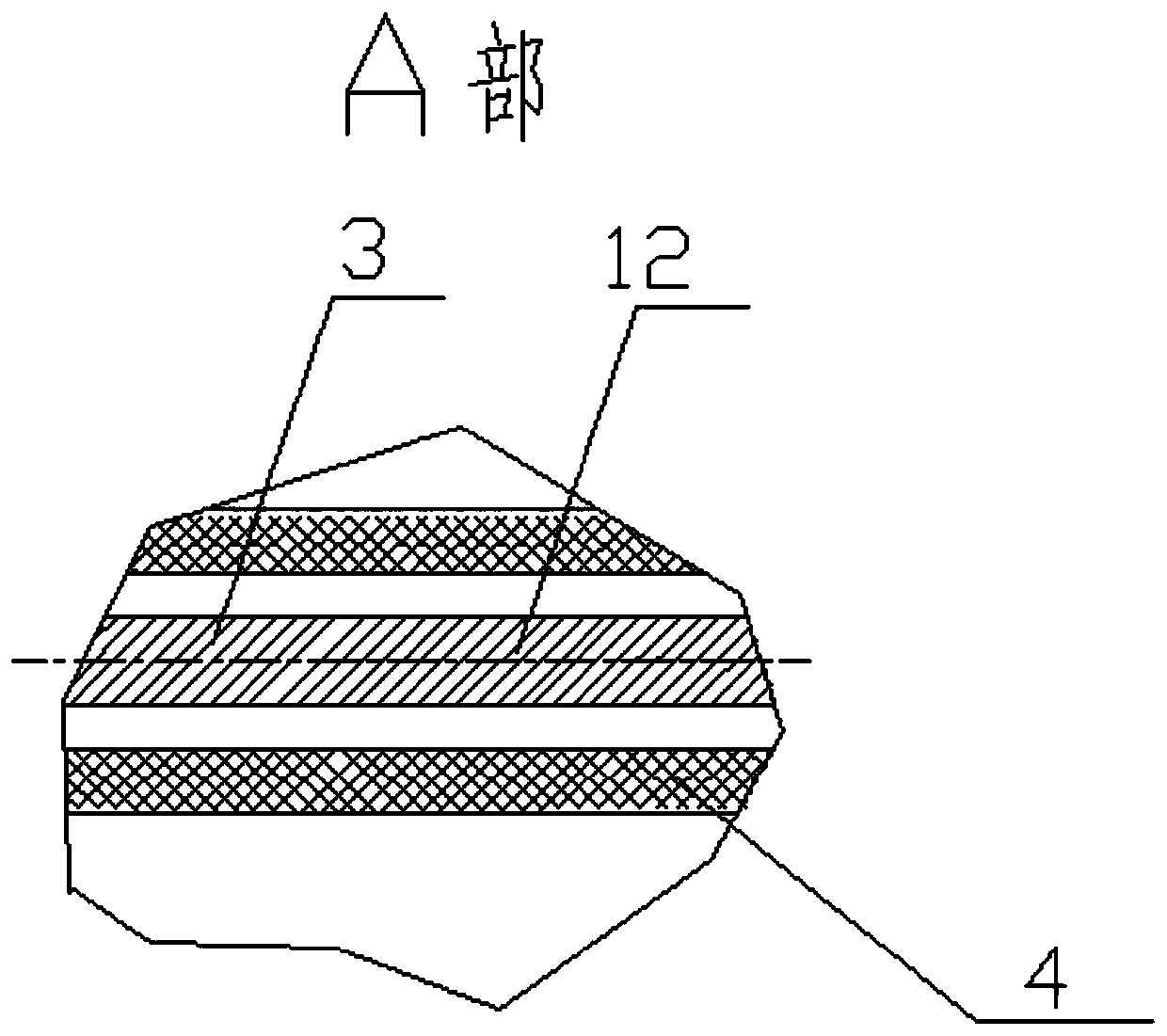

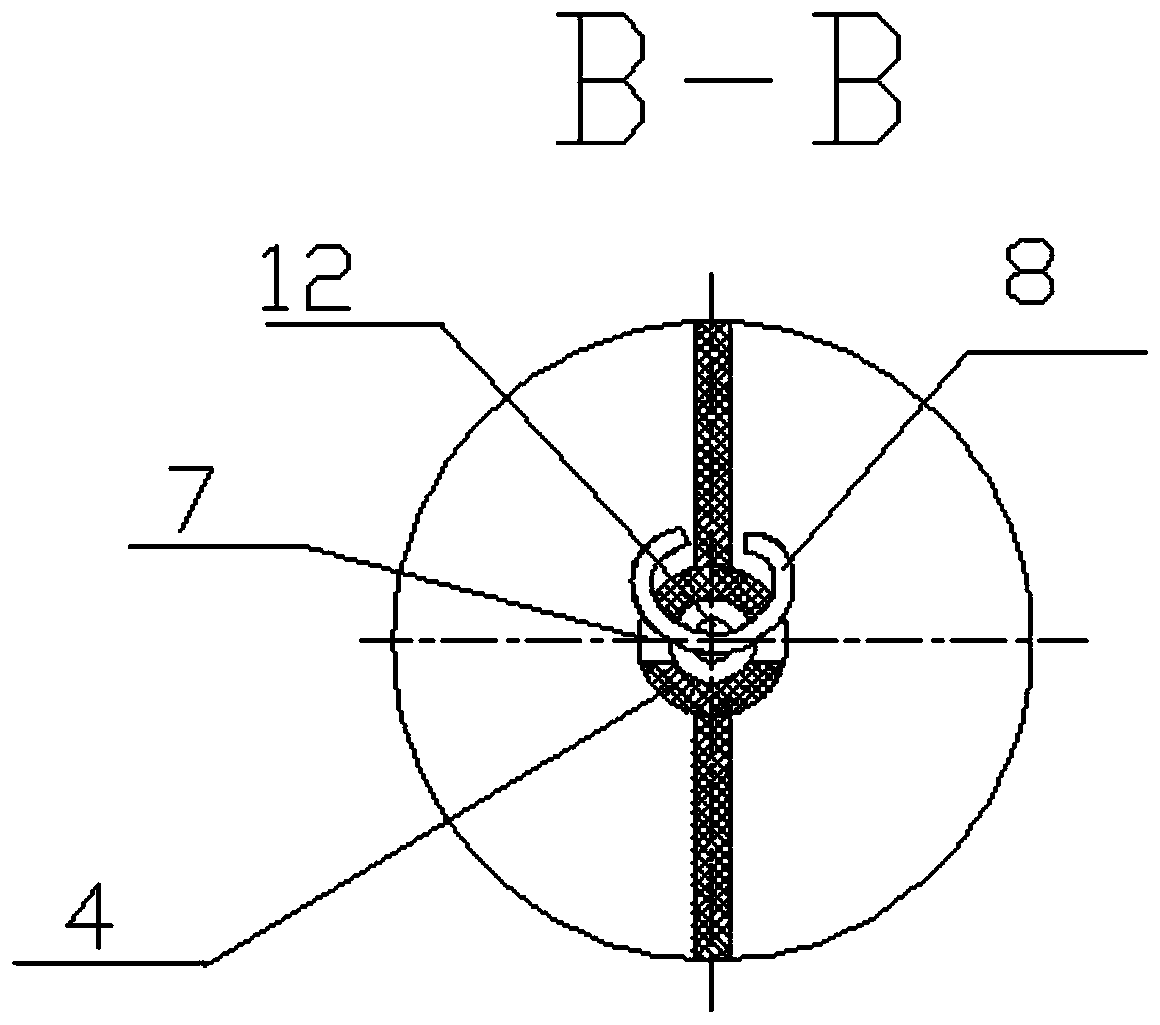

[0018] Attached below figure 1 , accompanying drawing 2, accompanying drawing 3, accompanying drawing 4, the present invention is described in further detail.

[0019] In the figure 1. Inclined end face bearing 2. Inflow window 3. Hook head shaft 4. Plastic double helix 5. Plastic tie 6. Heat exchange tube 7. Plastic double helix tie 8 Tube plate 9 Drag reduction hole 10 Inclined height difference 11 Inclined End face wear allowance 12 fixed section of cannula

[0020] The invention relates to an automatic cleaning technology for plastic double-helix bonds, which is suitable for automatic cleaning of hard scale in horizontal tube and tube heat exchangers and enhancement of convective heat transfer. This plastic double-helix bond automatic cleaning technology has a plastic double-helix bond 7, an inclined end face bearing 1, and a hook head shaft 3 to form an automatic cleaning mechanism. The plastic double helix tie 7, the hook head shaft 3 and the slanted end bearing 1 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com