Monitoring method and monitoring equipment for monocrystal diamond growth process

A single crystal diamond, growth process technology, applied in measurement devices, instruments, optical devices, etc., can solve the problems of inability to monitor the growth of single crystal diamond, cost waste, and inability to observe polycrystals or inclusions in real time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

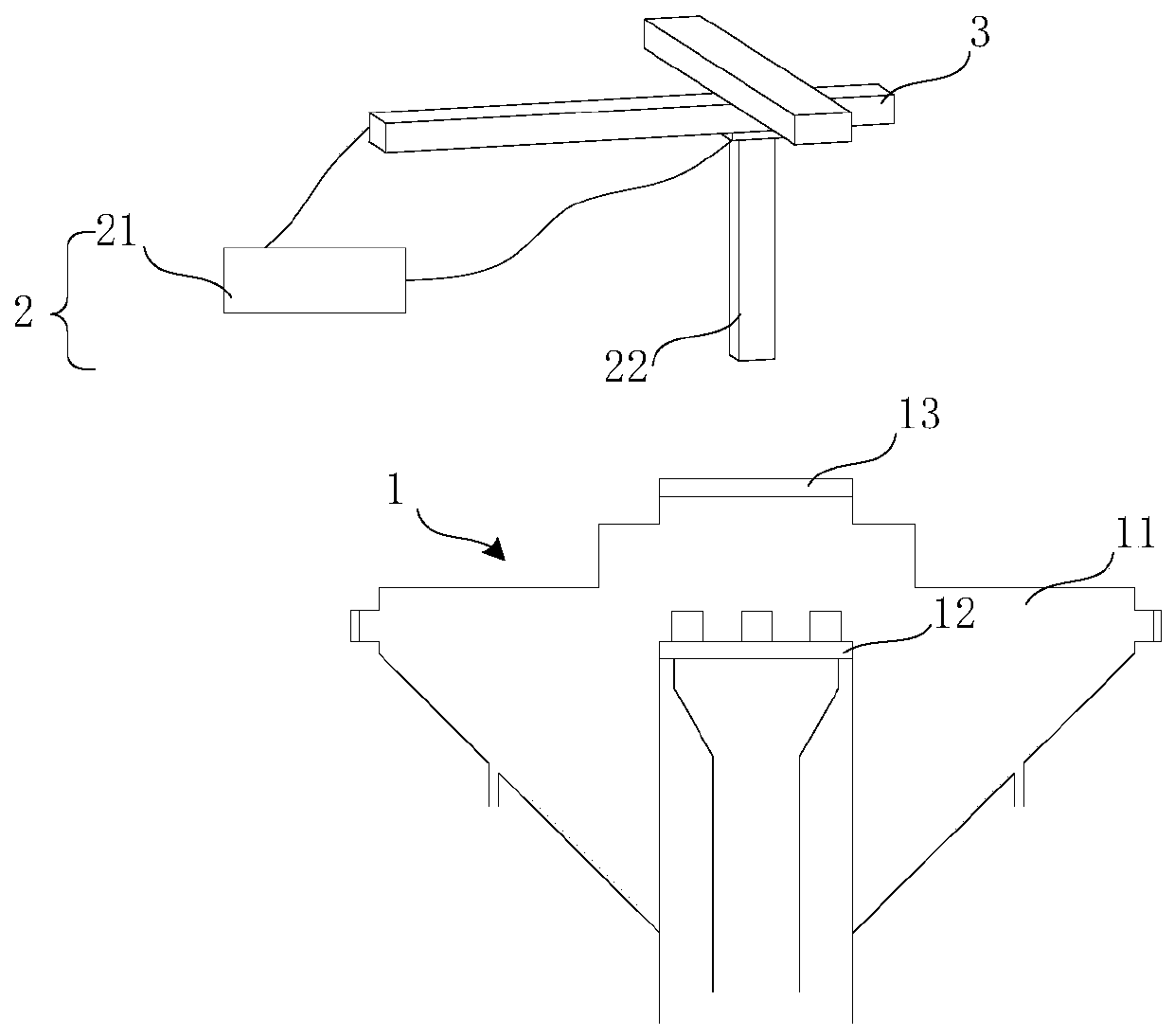

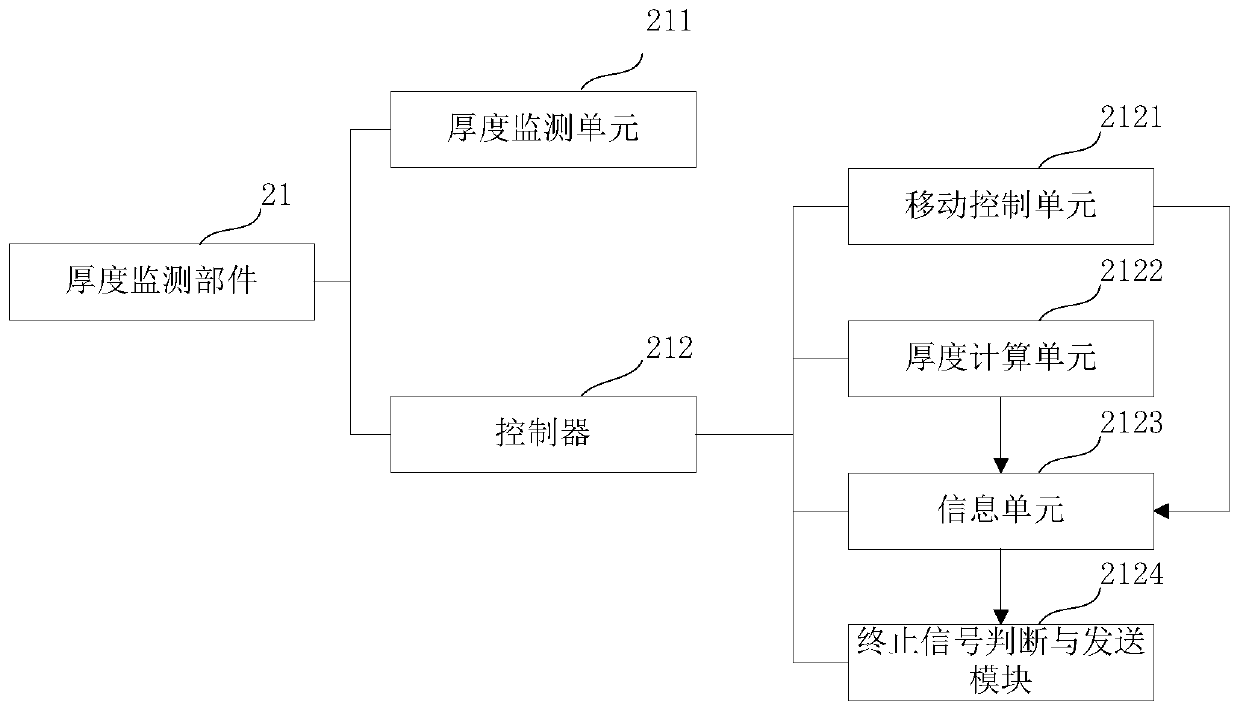

[0119] A monitoring method (single single crystal diamond) of a single crystal diamond growth process, comprising the steps:

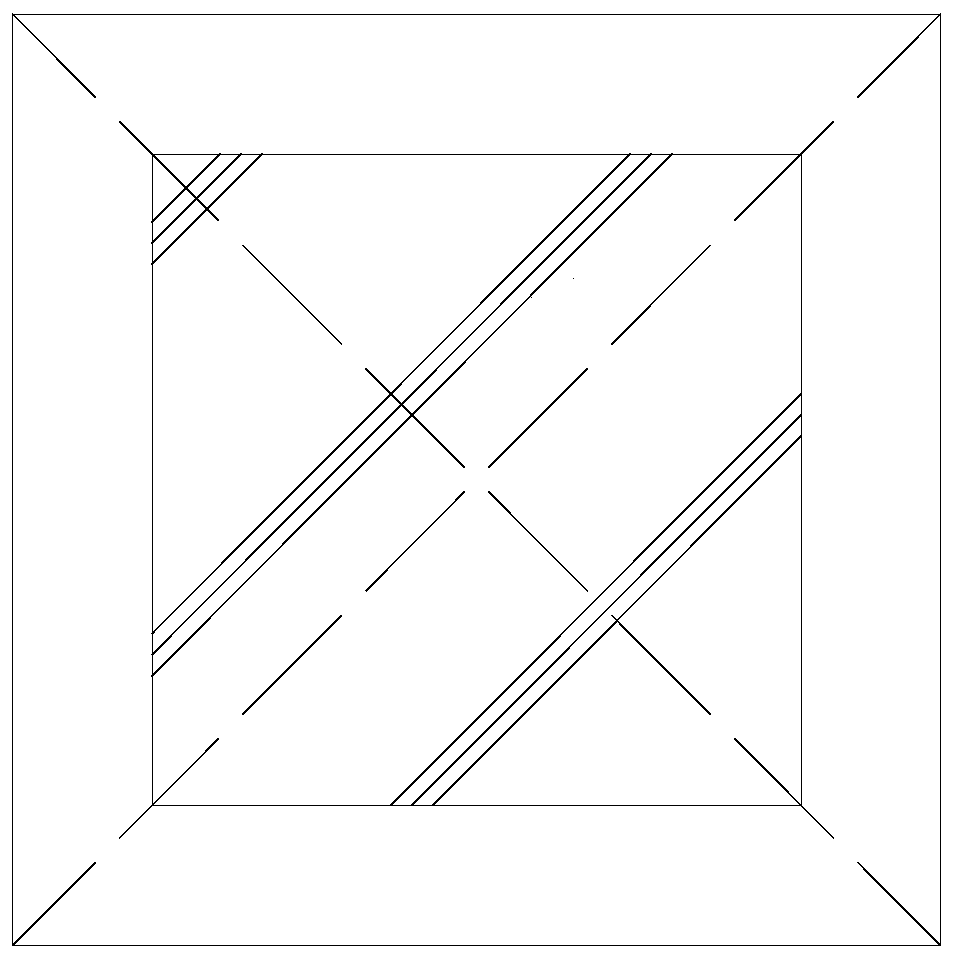

[0120] 1) Before the growth of single crystal diamond, the mobile thickness monitoring equipment performs optical thickness measurement on the surface of single crystal diamond seed crystal (8mm*8mm), and obtains the initial thickness and position data corresponding to each detection point on the surface of single crystal diamond;

[0121] 2) During the growth process of single crystal diamond, the mobile thickness monitoring equipment performs optical thickness measurement on the surface of single crystal diamond, and obtains the corresponding thickness and position data of each detection point on the surface of single crystal diamond during the growth process;

[0122] 3) According to the thickness and position data corresponding to each detection position on the initial single crystal diamond surface obtained in step 1), and the thickness and positio...

Embodiment 2

[0130] A monitoring method (simultaneously growing 9 single crystal diamonds) of a single crystal diamond growth process, comprising the steps:

[0131] 1) Before the growth of single crystal diamond, the mobile thickness monitoring equipment performs optical thickness measurement on the surface of single crystal diamond seed crystal (8mm*8mm), and obtains the initial thickness and position data corresponding to each detection point on the surface of single crystal diamond;

[0132] 2) During the growth process of single crystal diamond, the mobile thickness monitoring equipment performs optical thickness measurement on the surface of single crystal diamond, and obtains the corresponding thickness and position data of each detection point on the surface of single crystal diamond during the growth process;

[0133] 3) According to the thickness and position data corresponding to each detection position on the initial single crystal diamond surface obtained in step 1), and the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com