Follow-up high-temperature flammable gas sealing device applied to testing machine

A technology of flammable gas and sealing device, which is applied in the direction of engine sealing, measuring device, mechanical equipment, etc., can solve the problems of low adaptability to working conditions, difficult manufacturing, poor sealing effect, etc., to achieve a wide range of testing and applicable scope Flexible and accurate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

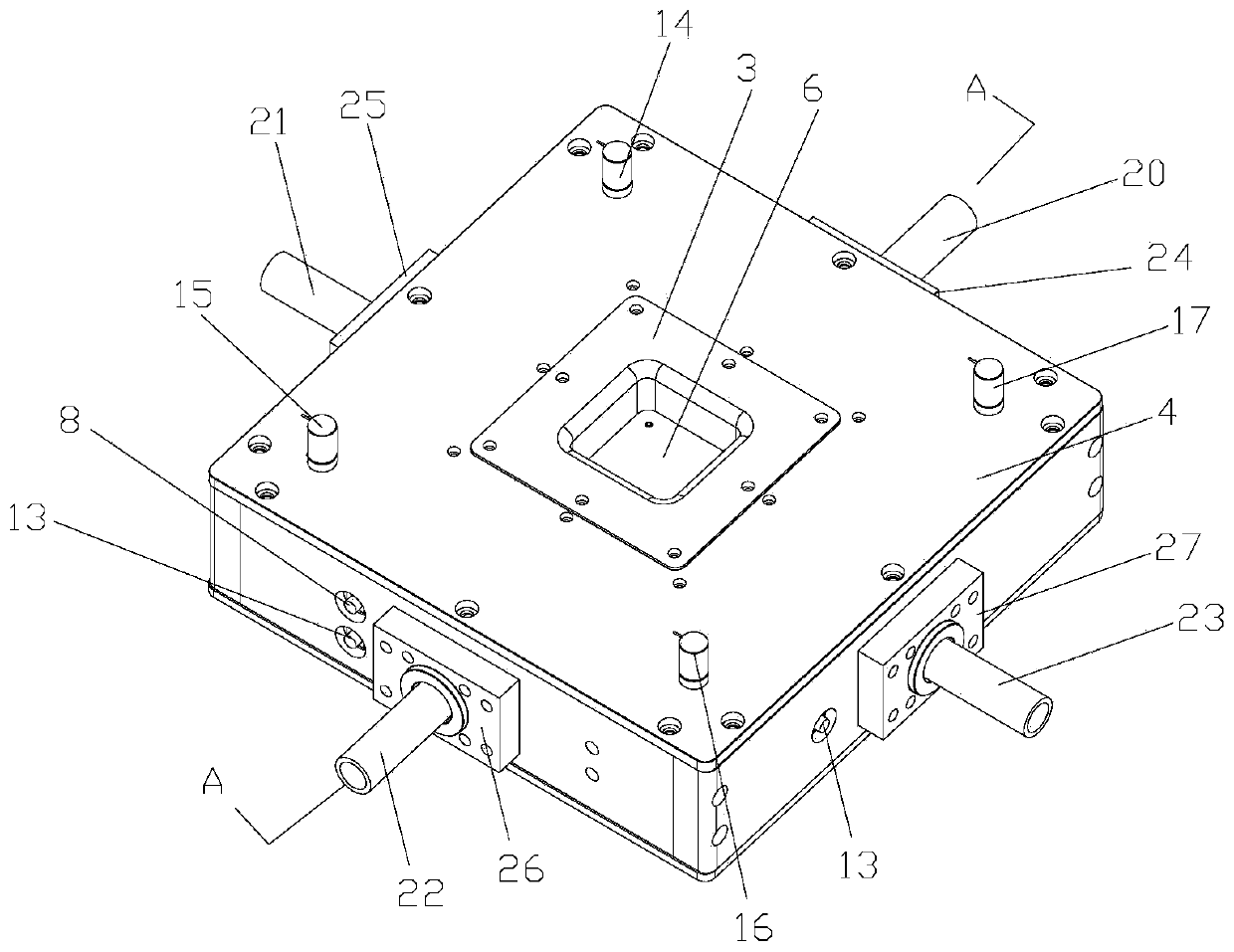

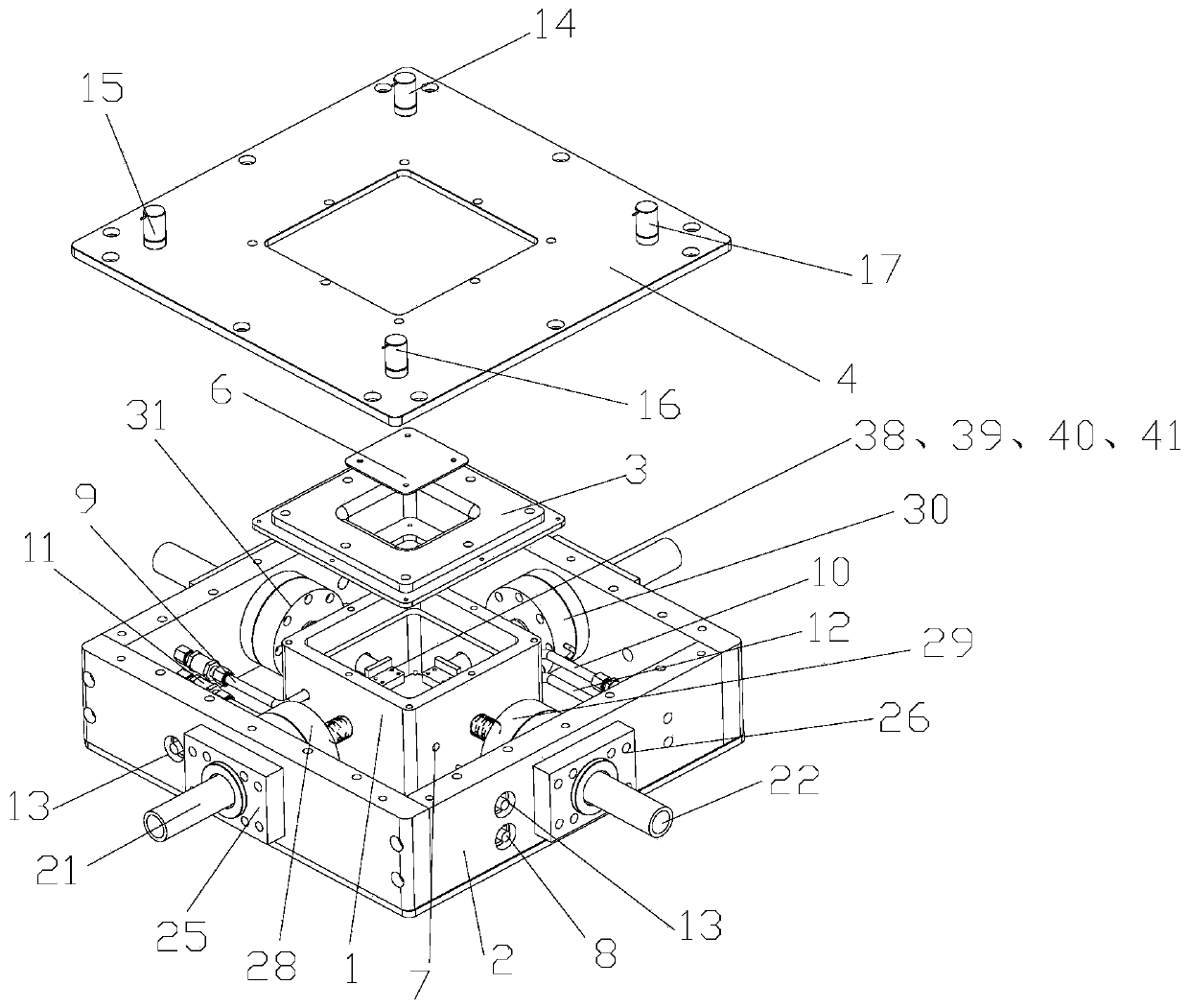

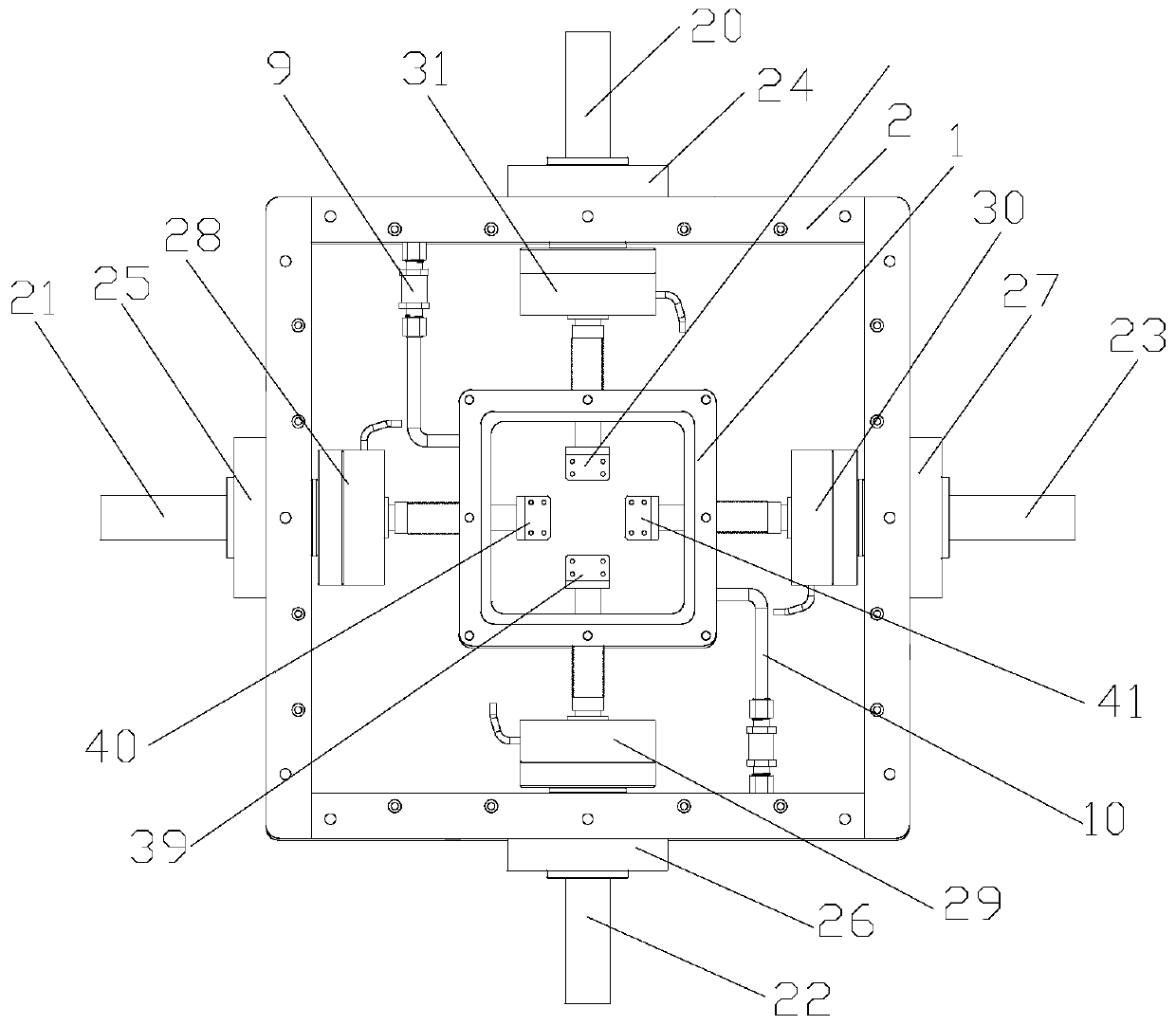

[0029] A follow-up type high-temperature flammable gas sealing device applied to a testing machine of the present invention will be described in detail below in conjunction with the embodiments and drawings.

[0030] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a follow-up type high-temperature flammable gas sealing device applied to a testing machine of the present invention includes an outer cavity 2 and an inner cavity 1 fixed in the middle of the outer cavity 2, and the inner cavity 1 realizes sealing The key device, the outer cavity body 2 is the inspection of the sealing effect and the secondary protection device, all of which can be made of stainless steel. The four sides of the inner cavity 1 are symmetrically provided with plate fixtures 38, 39, 40, 41 for fixing the workpiece to be measured, the inner cavity 1 is provided with an inner cavity sealing upper cover 3, and the outer cavity The body 2 is provided with a rectangular annular outer cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com