High-power fiber laser modular heat management device capable of realizing spatiotemporal modulation of temperature distribution

A fiber laser and temperature distribution technology, applied in the field of lasers, can solve the problems of water-cooled cooling power and high cooling efficiency, and achieve the effect of isolating heat transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

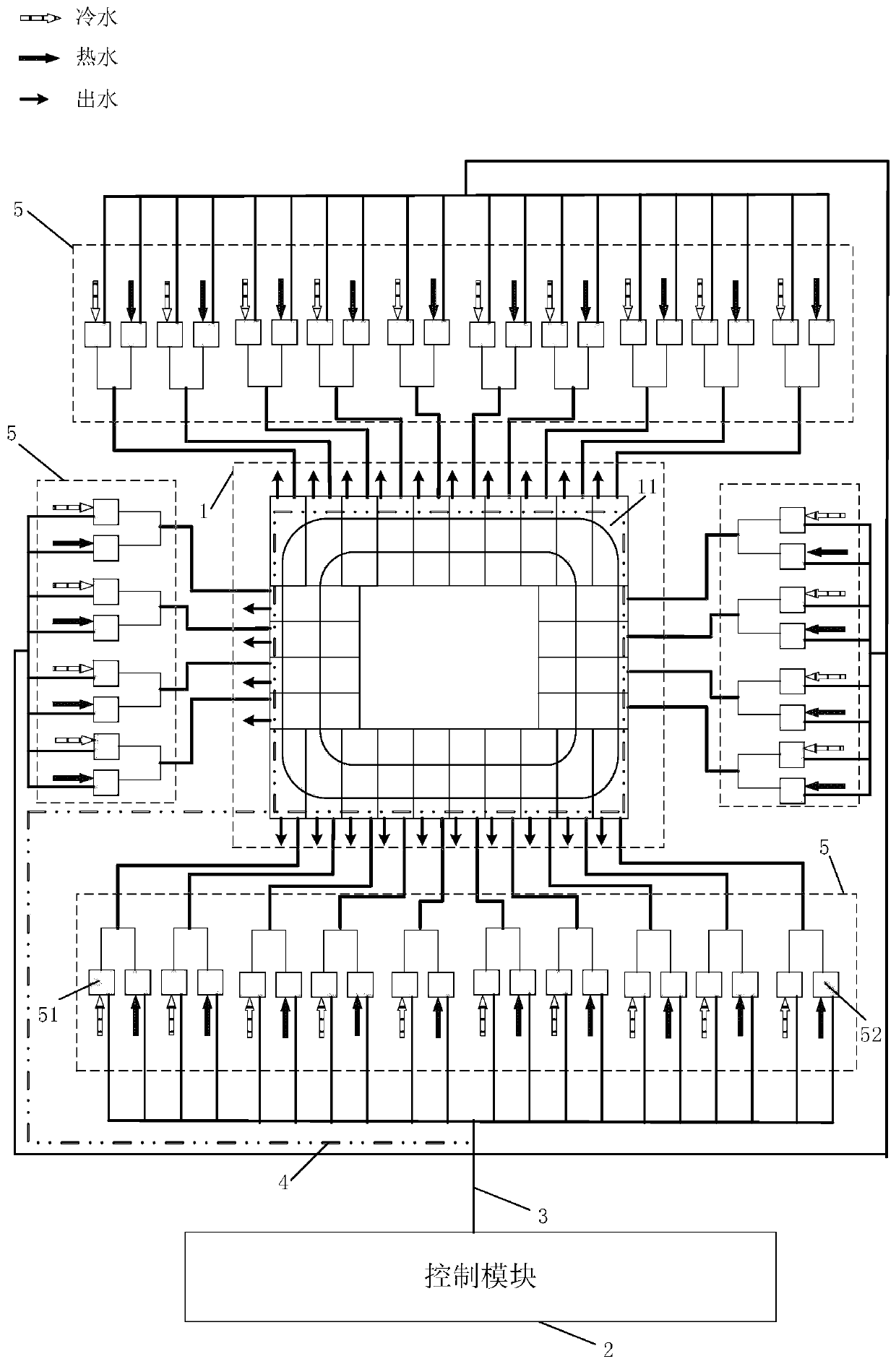

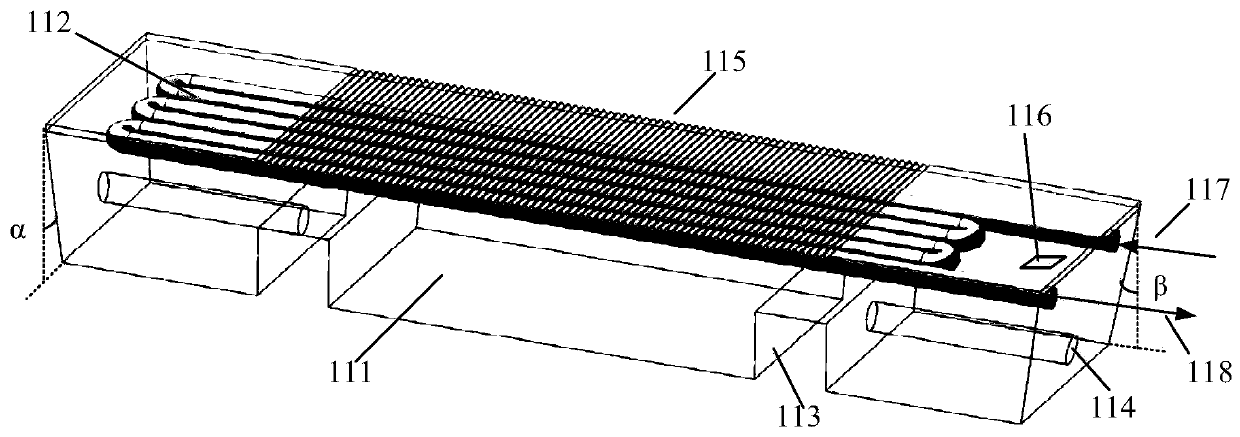

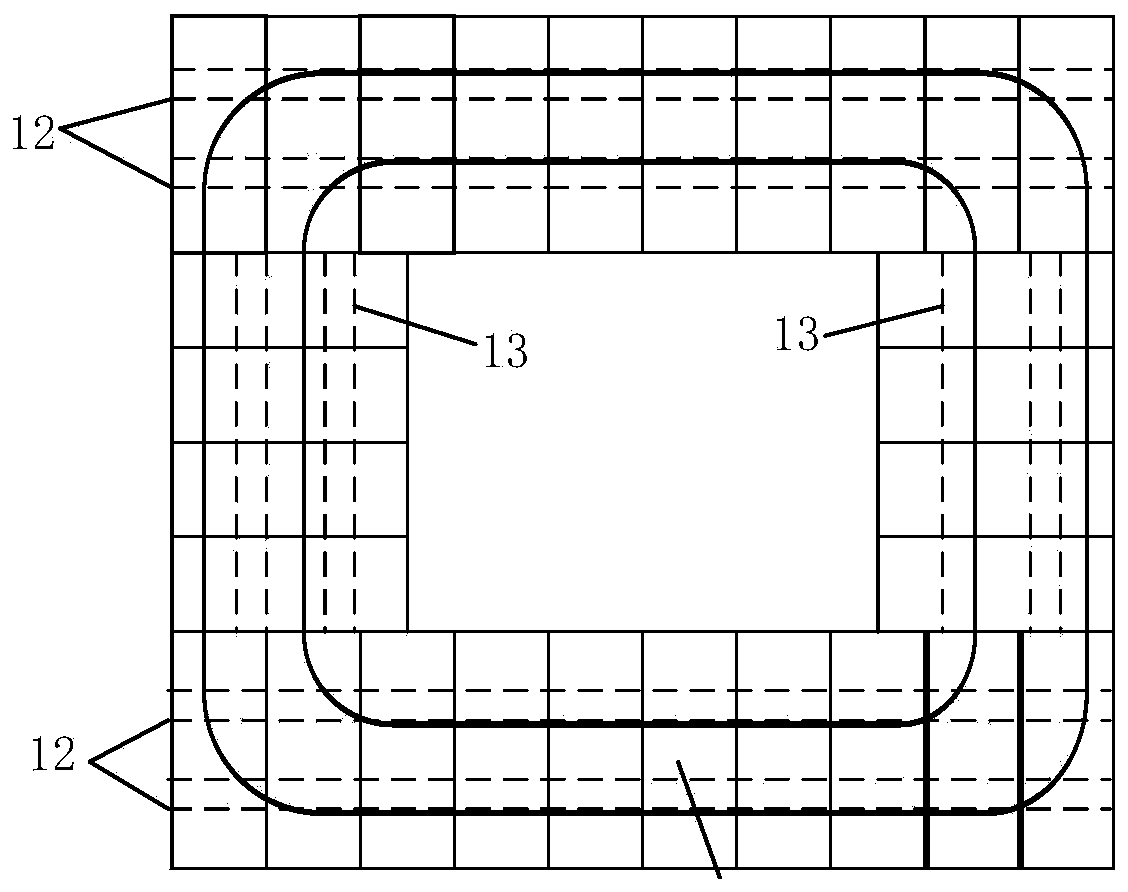

[0033] A modular thermal management device for high-power fiber lasers whose temperature distribution can be controlled spatiotemporally. Its structure is shown as figure 1 As shown, it includes a modular water-cooling plate 1, a control module 2, a control bus 3, a data bus 4, and a water temperature rapid regulation module 5: the control module 2 is connected to the control bus 3 and the data bus 4, and the water temperature rapid regulation module 5 is composed of multiple The cold water electronic flow valve 51 and the hot water electronic flow valve 52 corresponding to the thermostat 2 are composed, the control bus 3 is respectively connected to the cold water electronic flow valve 51 and the hot water electronic flow valve 52 of the water temperature rapid regulation module 5, and the data bus 4 is respectively connected to each The temperature sensor 116 on the optical fiber temperature regulating part. The cold water electronic flow valve 51 is connected to the cold wa...

Embodiment 2

[0037] A thermal management method for realizing the time-space modulation of the temperature distribution of high-power lasers, which uses the high-power fiber laser modular thermal management device whose temperature distribution can be time-space-controlled in the above-mentioned embodiment 1. The specific method process is as follows. First, each temperature module 11 set temperature T i The fitting is obtained, with Figure 6 It is the temperature fitting curve of the water cooling plate in a certain embodiment, the abscissa is the number of optical fiber temperature adjustment parts, unit: piece, the ordinate is the temperature, unit: °C, the temperature curve is divided into 28 intervals, representing 28 optical fiber temperature adjustment parts Temperature parts, preferably, take the median T of the temperature distribution in each interval i (i=1,2...28) as the set temperature of the corresponding optical fiber temperature adjustment parts (such as Figure 6 As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com