Magnetic levitation motor and air conditioner

A technology of magnetic levitation and magnetic levitation bearing, which is applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of special occasions that cannot be applied to narrow space, large size of the whole machine, and limited application scope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

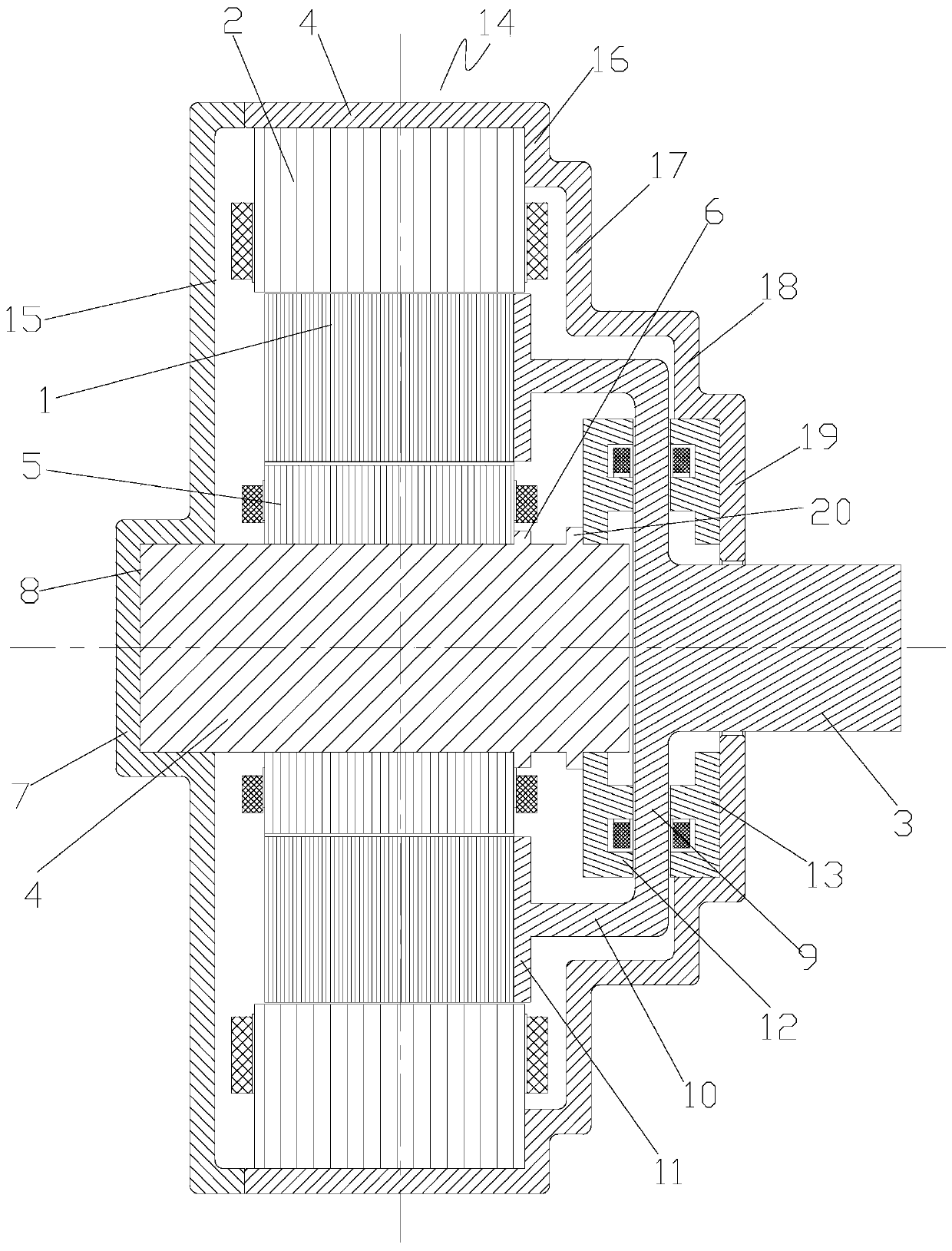

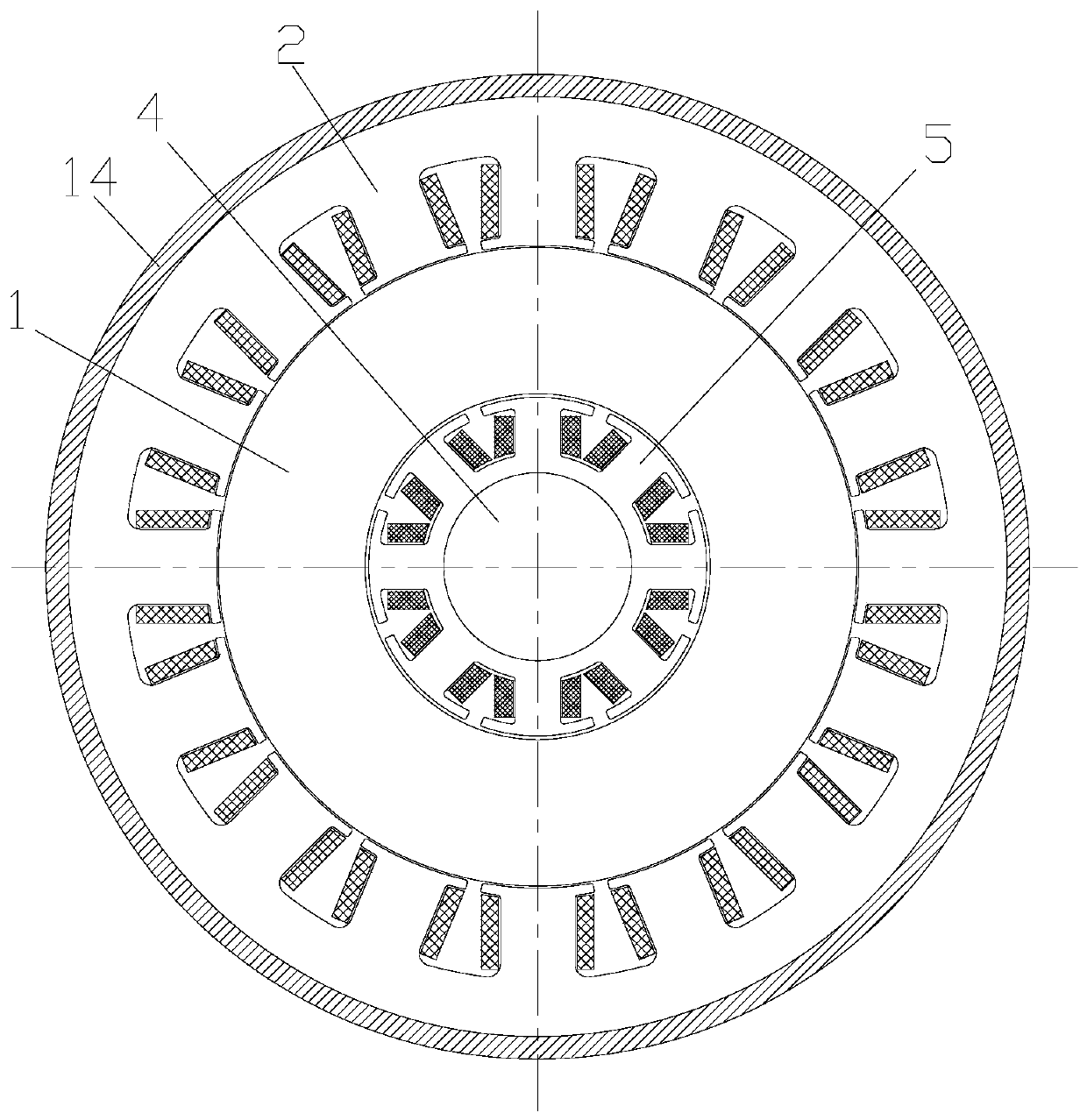

[0026] see in conjunction Figure 1 to Figure 2 As shown, according to the embodiment of the present application, the magnetic levitation motor includes a housing, a rotor assembly 1, a stator assembly 2, a main shaft 3, a mounting frame 4, a radial magnetic levitation bearing 5 and an axial bearing, and the mounting frame 4 is fixedly arranged on the housing , the radial magnetic suspension bearing 5 is fixedly installed on the mounting frame 4, the rotor assembly 1 is sleeved on the outer periphery of the radial magnetic suspension bearing 5, the stator assembly 2 is sleeved on the outer circumference of the rotor assembly 1, and the main shaft 3 is arranged on the axial outer side of the rotor assembly 1, And it is fixedly connected with the rotor assembly 1 , the axial bearing is used to adjust the axial position of the main shaft 3 , and the radial magnetic suspension bearing 5 is used to adjust the radial position of the rotor assembly 1 .

[0027] In this magnetic levit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com