Liftable mobile ladder stand and working method thereof

A lifting and climbing technology, applied in the direction of ladders, buildings, building structures, etc., can solve the problems of poor stability, labor-intensive, no operation platform, etc., and achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

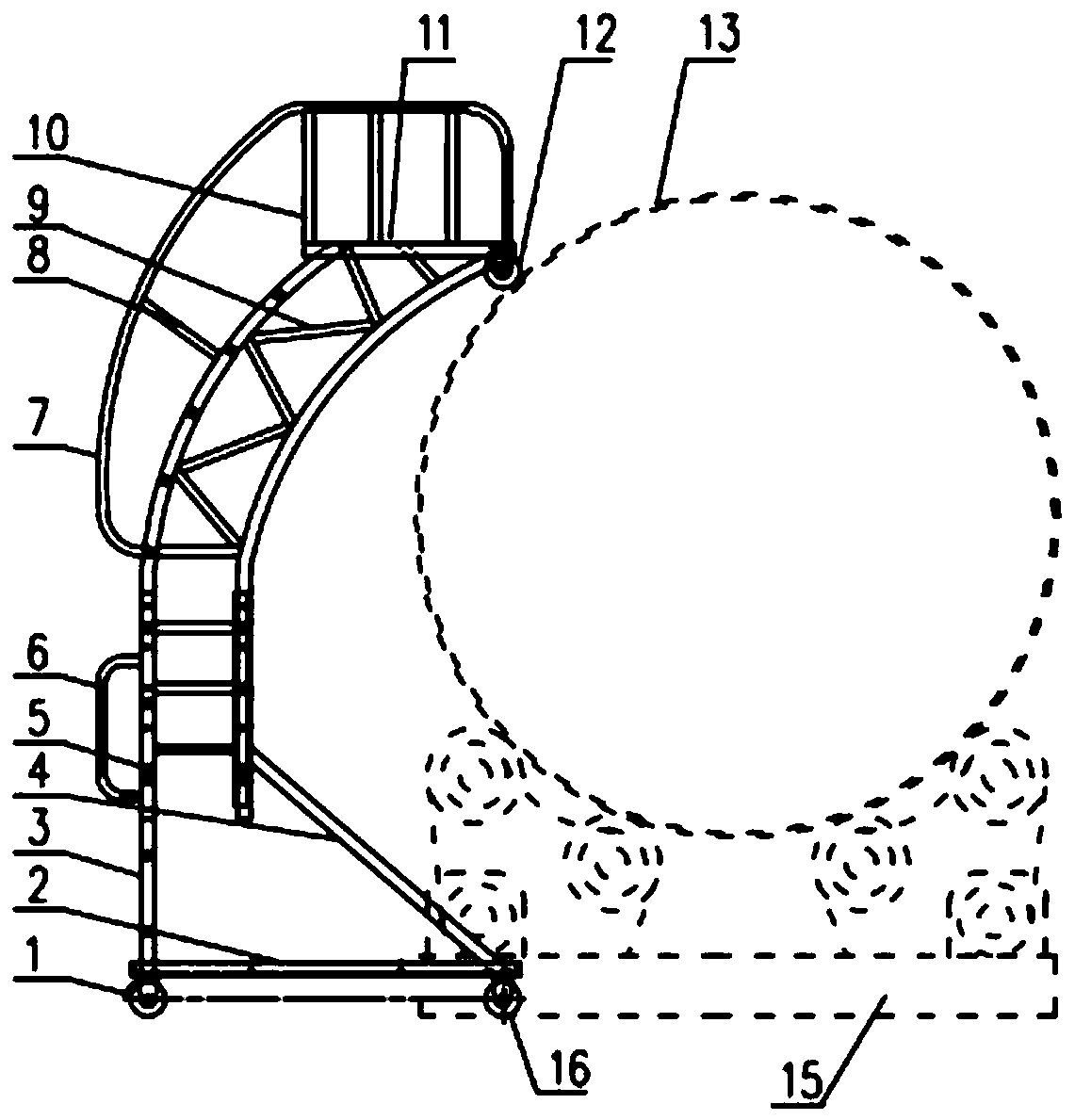

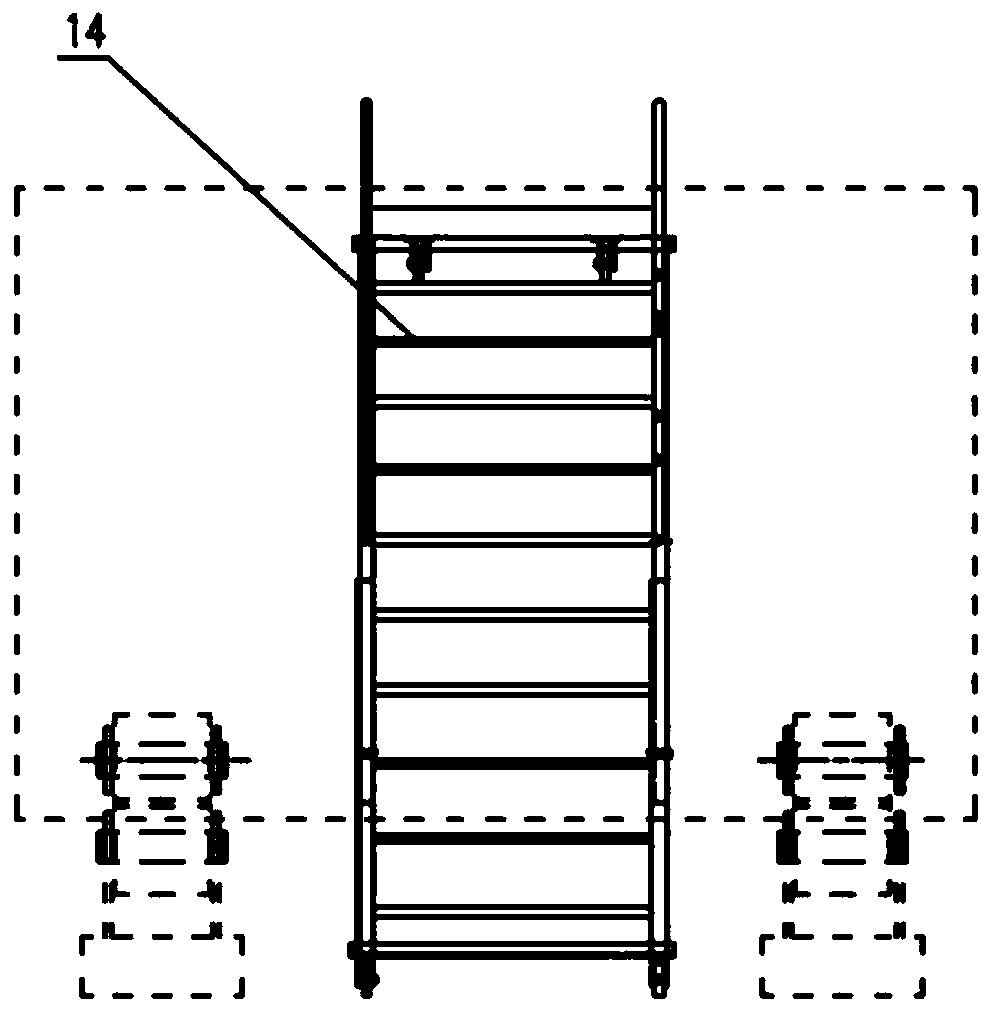

[0027] Such as Figure 1 to Figure 2 As shown, the present embodiment 1 provides a liftable mobile climbing ladder, comprising: a lower ladder part and an arc-shaped upper ladder part; a sliding wheel 12 is provided on the top side of the upper ladder part; the sliding wheel 12 It is suitable for abutting against the outer wall of a cylinder to be welded 13; and the upper ladder part is connected with the lower ladder part through a height adjustment assembly.

[0028] Specifically, the liftable mobile ladder of this embodiment facilitates approaching the outer wall of the cylinder 13 to be welded through the arc-shaped upper ladder, and realizes effective contact with the outer wall of the cylinder 13 to be welded through the sliding wheel 12, the sliding wheel 12 It can rotate following the rotation of the cylinder 13 to ensure the stability of welding; in addition, the liftable mobile ladder can also adjust the installation height of the upper ladder through the height adju...

Embodiment 2

[0045] On the basis of embodiment 1, this embodiment 2 provides a working method of a liftable mobile ladder, including: pressing against the outer wall of a cylinder to be welded by a sliding wheel arranged on the top side of the upper ladder part; And the installation height of the upper ladder part installed on the lower ladder part is adjusted by the height adjustment assembly.

[0046] Specifically, for the specific structure and working principle of the liftable mobile ladder in this embodiment, refer to the description in Embodiment 1, which will not be repeated here.

[0047] In summary, the liftable mobile ladder of the present application facilitates access to the outer wall of the cylinder to be welded through the arc-shaped upper ladder, and realizes effective contact with the outer wall of the cylinder to be welded through the sliding wheels, which can follow the cylinder The rotation of the body rotates to ensure the stability of the welding; in addition, the lif...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap