Vehicle rear processor and rotary vane pipe thereof

A post-processor and rotary vane tube technology, which is applied in the direction of exhaust treatment, machines/engines, mechanical equipment, etc., can solve the problems of insufficient vaporization effect and uniformity, and a large amount of urea crystallization, so as to improve the vaporization effect and uniformity sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

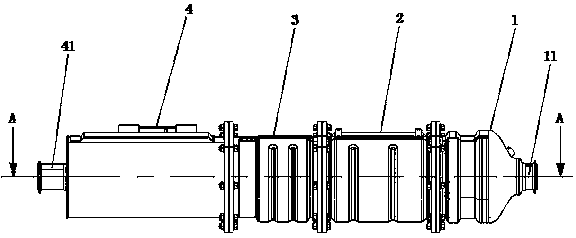

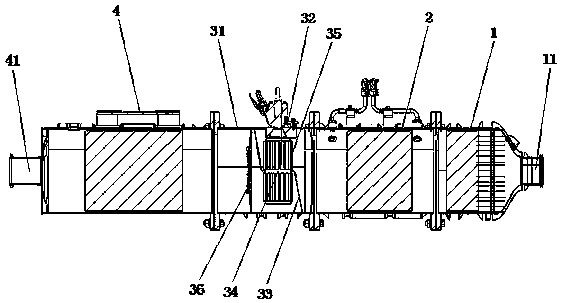

[0024] Such as Figures 1 to 6 As shown, the vehicle afterprocessor of the present invention includes a DOC oxidation catalyst 1 , a PDF particle trap 2 , a urea mixing box 3 and an SCR catalytic box assembly 4 .

[0025] The DOC oxidation catalytic converter 1 is located at the front of the afterprocessor and the front end is matched with an intake pipe 11 .

[0026] The PDF particle trap 2 is matched and installed at the rear end of the DOC oxidation catalyst 1; wherein, the front end of the PDF particle trap 2 is connected and fixed to the rear end of the DOC oxidation catalyst 1 through flange matching.

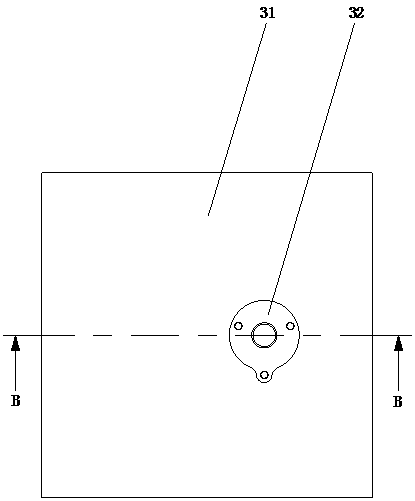

[0027] The urea mixing box 3 is matched and mounted on the rear end of the PDF particle catcher 2, which includes a mixing box housing 31, a nozzle seat 32, a support 33, an air guide pipe 34, a swirl pipe 35 and a mixer 36.

[0028] The inside of the mixing box housing 31 is a urea mixing chamber, and the front end is matched and fixed to the rear end of the PDF particl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com