Handheld turning gear

A turning device and hand-held technology, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of low maintenance efficiency, many manpower, material resources and time, and achieve the increase of rotational resistance and the attenuation of speed , the effect of reducing waiting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

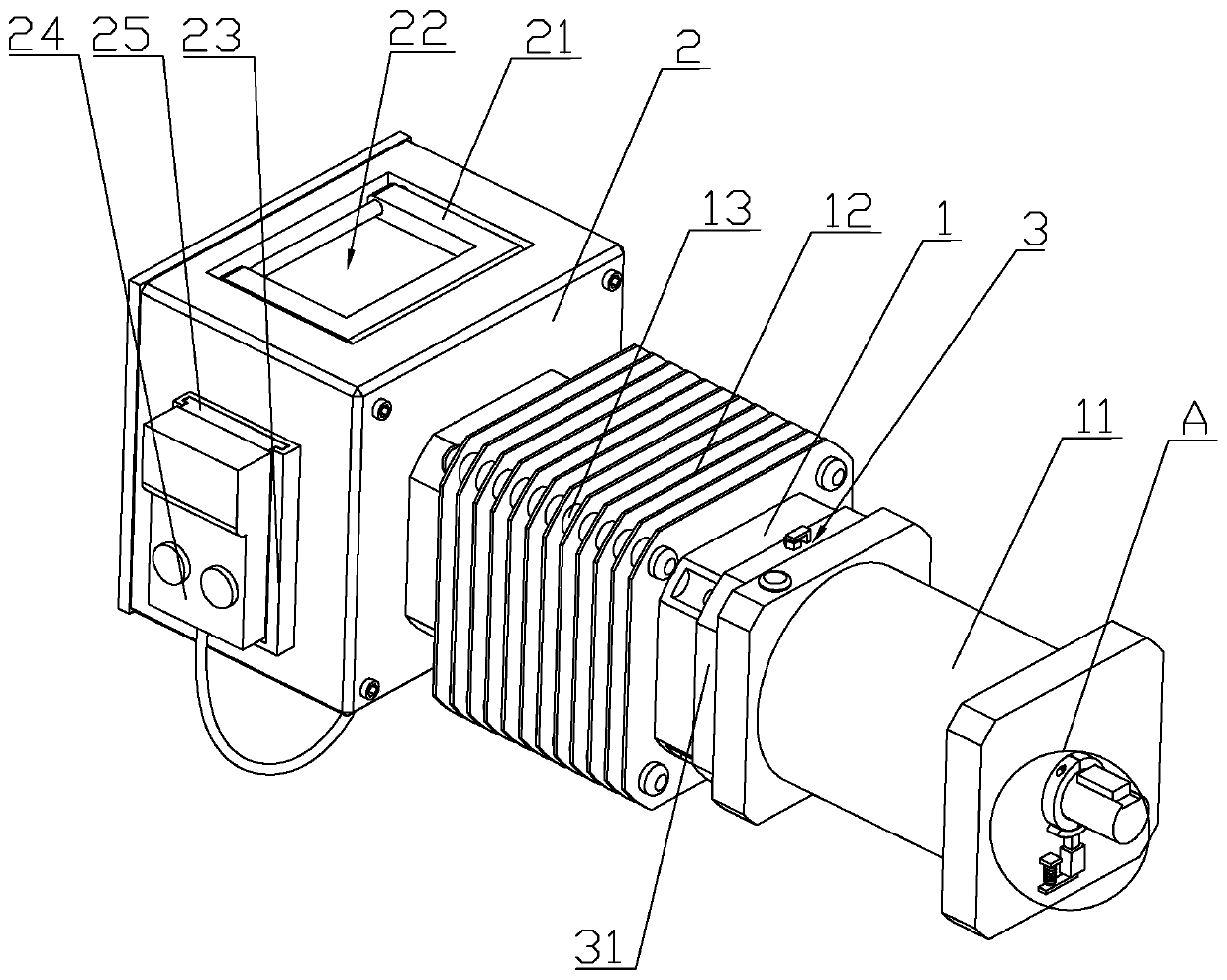

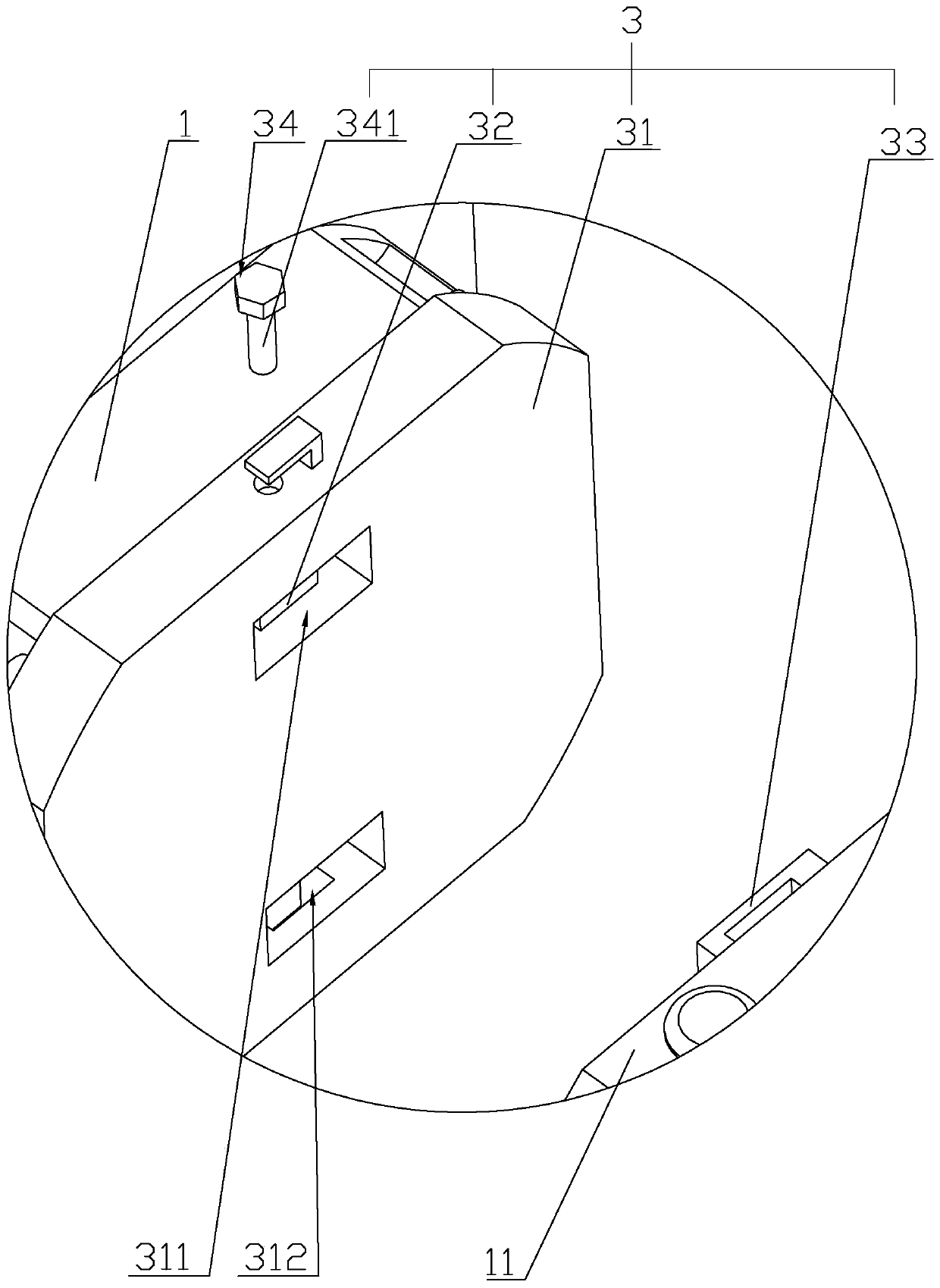

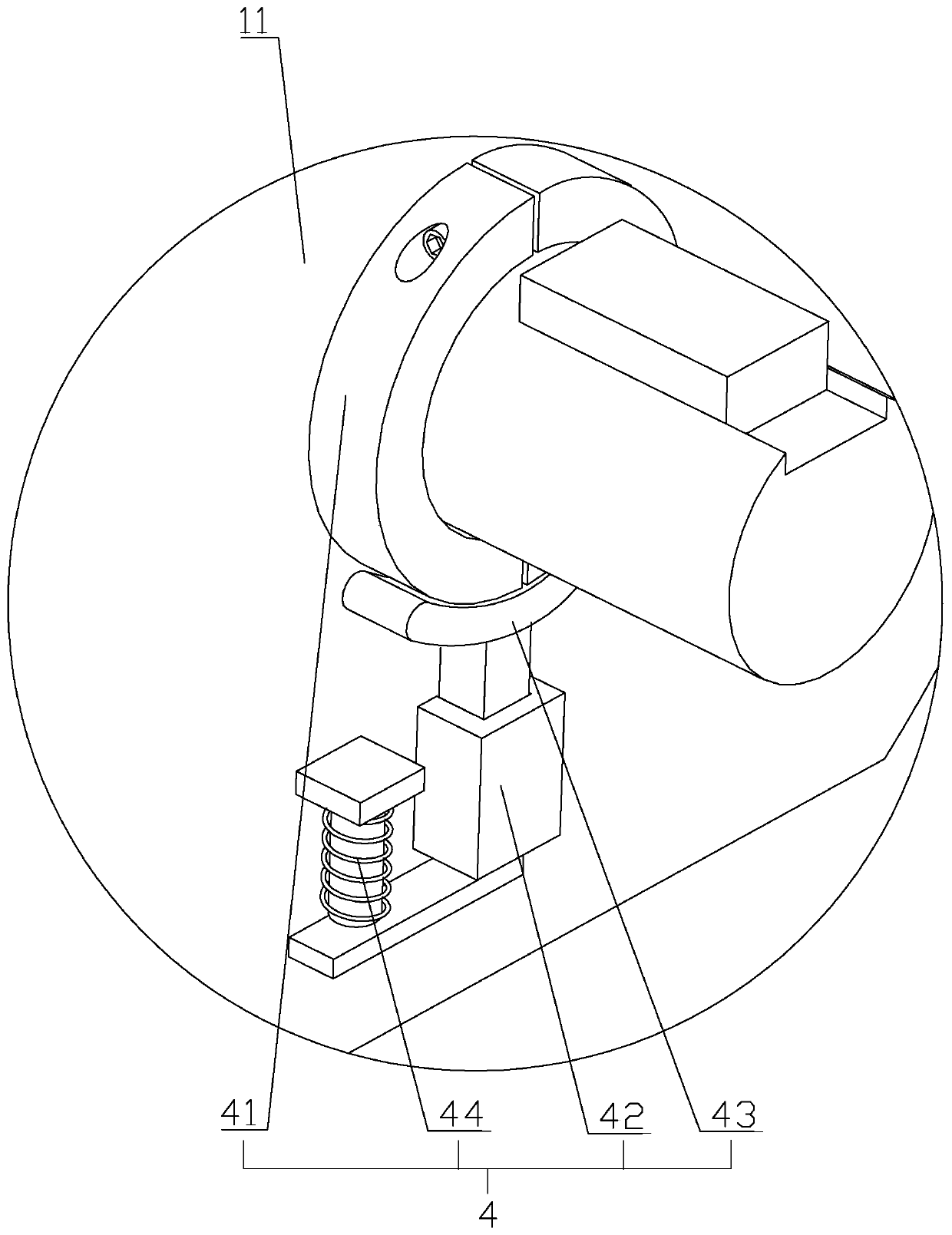

[0037] refer to figure 1 , is a hand-held turning device disclosed in the present invention, including a motor 1, a driver 2 arranged on the motor 1, a handle 24 electrically connected to the driver 2 to control the forward and reverse rotation of the motor 1, and a handle 24 arranged on one side of the motor 1 A speed reducer 11 for increasing the output torque of the motor 1 . The reducer 11 is coaxially fixed with the output shaft of the motor 1 , and a mounting mechanism 3 is arranged between the motor 1 and the reducer 11 . The driver 2 is electrically connected to the motor 1 to supply power to the motor 1. The motor 1 is a servo motor 1 with forward and reverse functions, and the handle 24 is electrically connected to the driver 2 to control the forward and reverse rotation of the motor 1 through the driver 2 . The reducer 11 adopts the PRF90-L1 mode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com