Asymmetric type centrifugal impeller fan

A centrifugal impeller, asymmetric technology, used in non-variable-capacity pumps, mechanical equipment, machines/engines, etc., can solve the problem of loud fan noise, reduce noise, improve installation and positioning accuracy, and reduce rotational noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

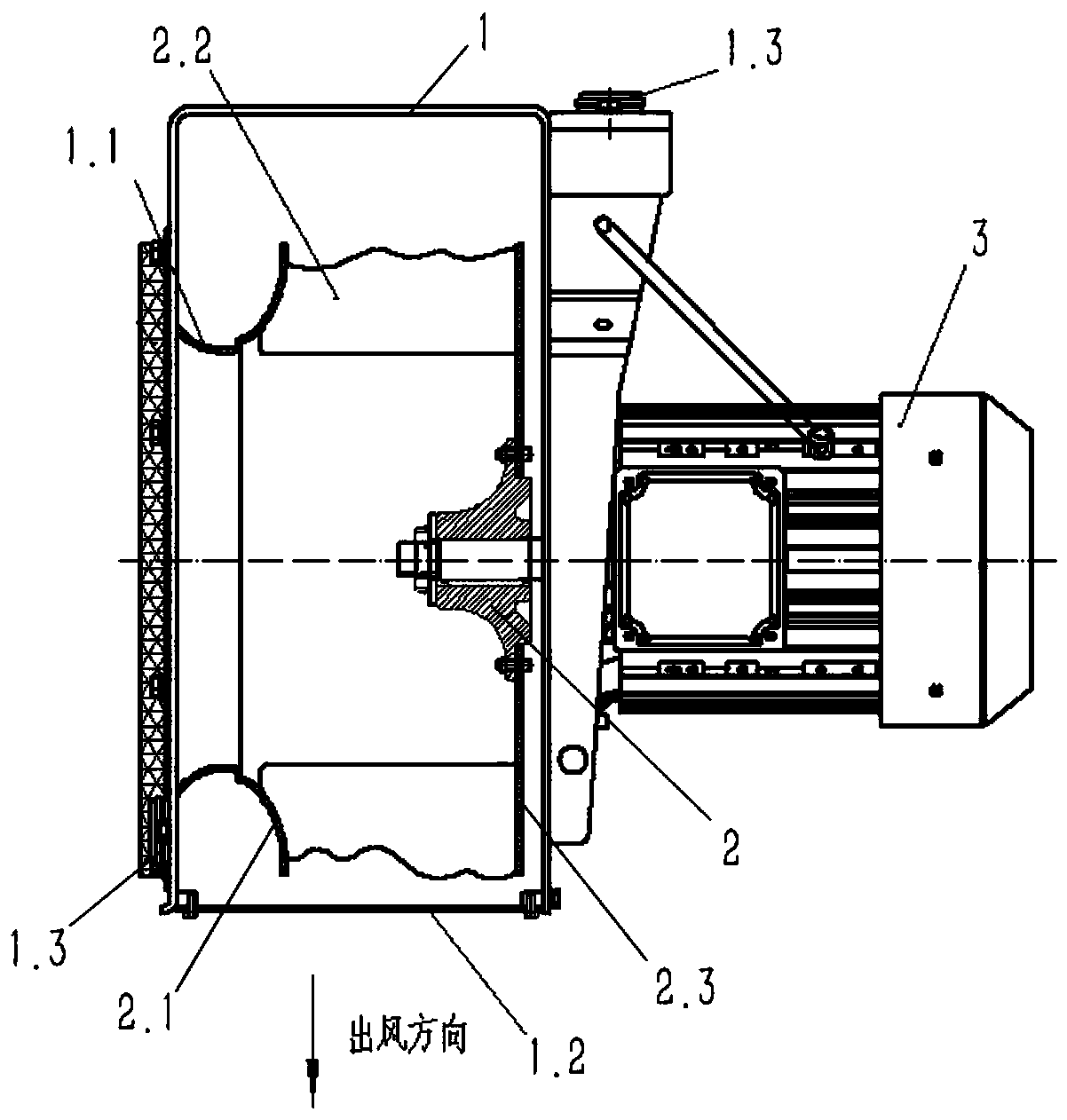

[0034] see Figure 1 to Figure 5 , an asymmetric centrifugal impeller fan, this embodiment is applied to the cooling and heat dissipation of locomotive traction transformers.

[0035] An asymmetric centrifugal impeller fan includes a casing 1, an impeller 2 and a motor 3; the impeller 2 is installed in the casing 1 and connected with the output shaft of the motor 3 to realize the rotation of the impeller 2;

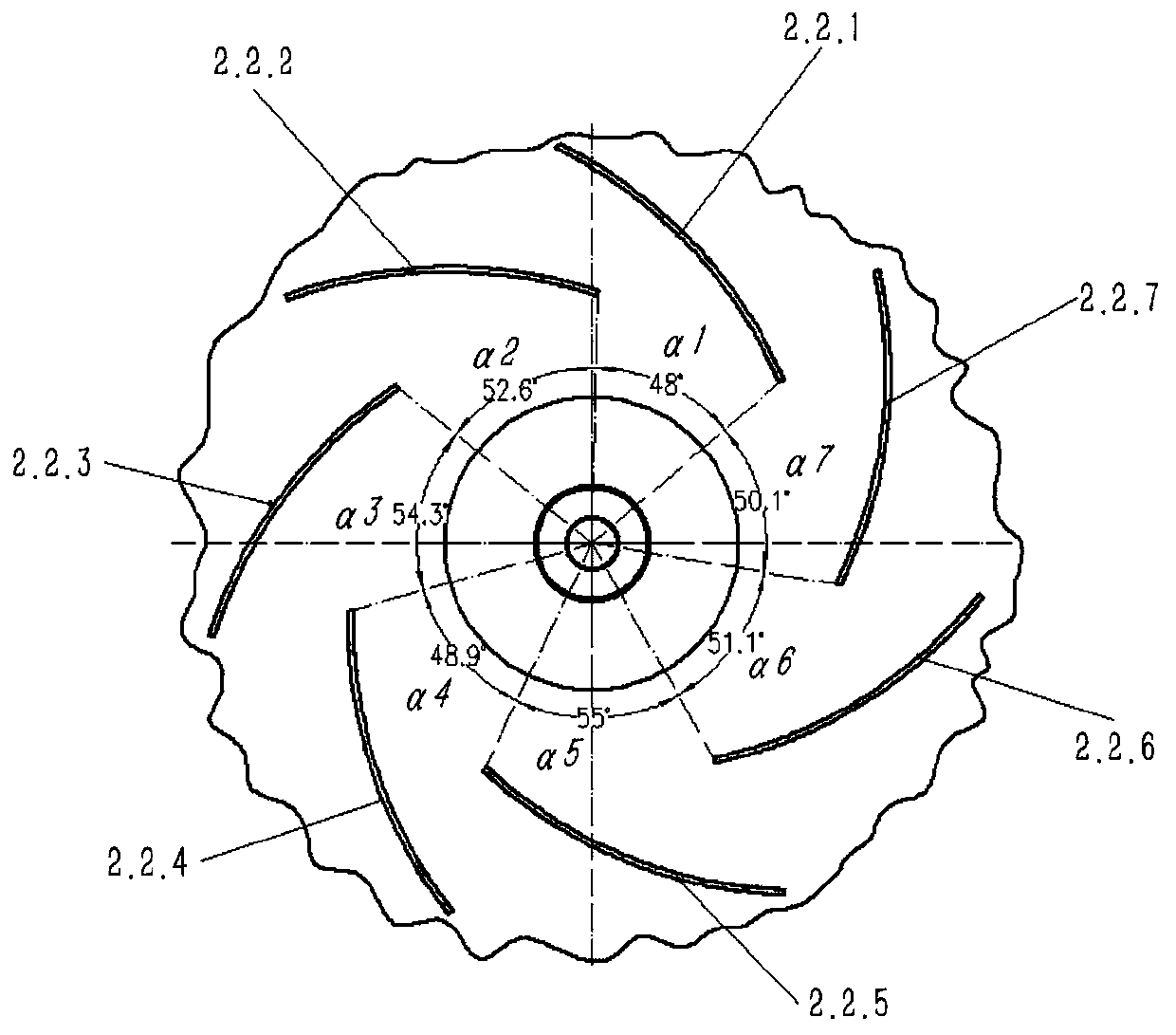

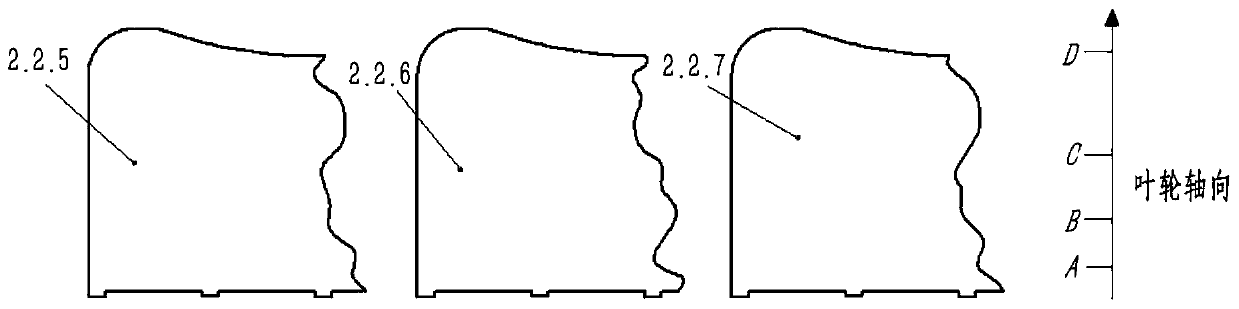

[0036] The impeller 2 includes a front disc 2.1, a blade 2.2 and a rear disc 2.3 connected sequentially along the axial direction of the impeller 2; see figure 1 and image 3 , the edge contour line of the free end of the blade 2.2 is an irregular curve, and the irregular curve is composed of arcs with different curvature radii, so as to avoid the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com