Quadrature-direct axis reluctance controllable permanent magnet brushless motor

A permanent magnet brushless motor, controllable technology, applied to synchronous motors with stationary armature and rotating magnets, magnetic circuit shape/style/structure, magnetic circuit, etc., can solve the problem of power density reduction and torque insufficiency Adjustment, air gap main magnetic flux is not high, etc., to achieve the effect of improving the utilization rate reduction, widening the speed regulation range, and high torque density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

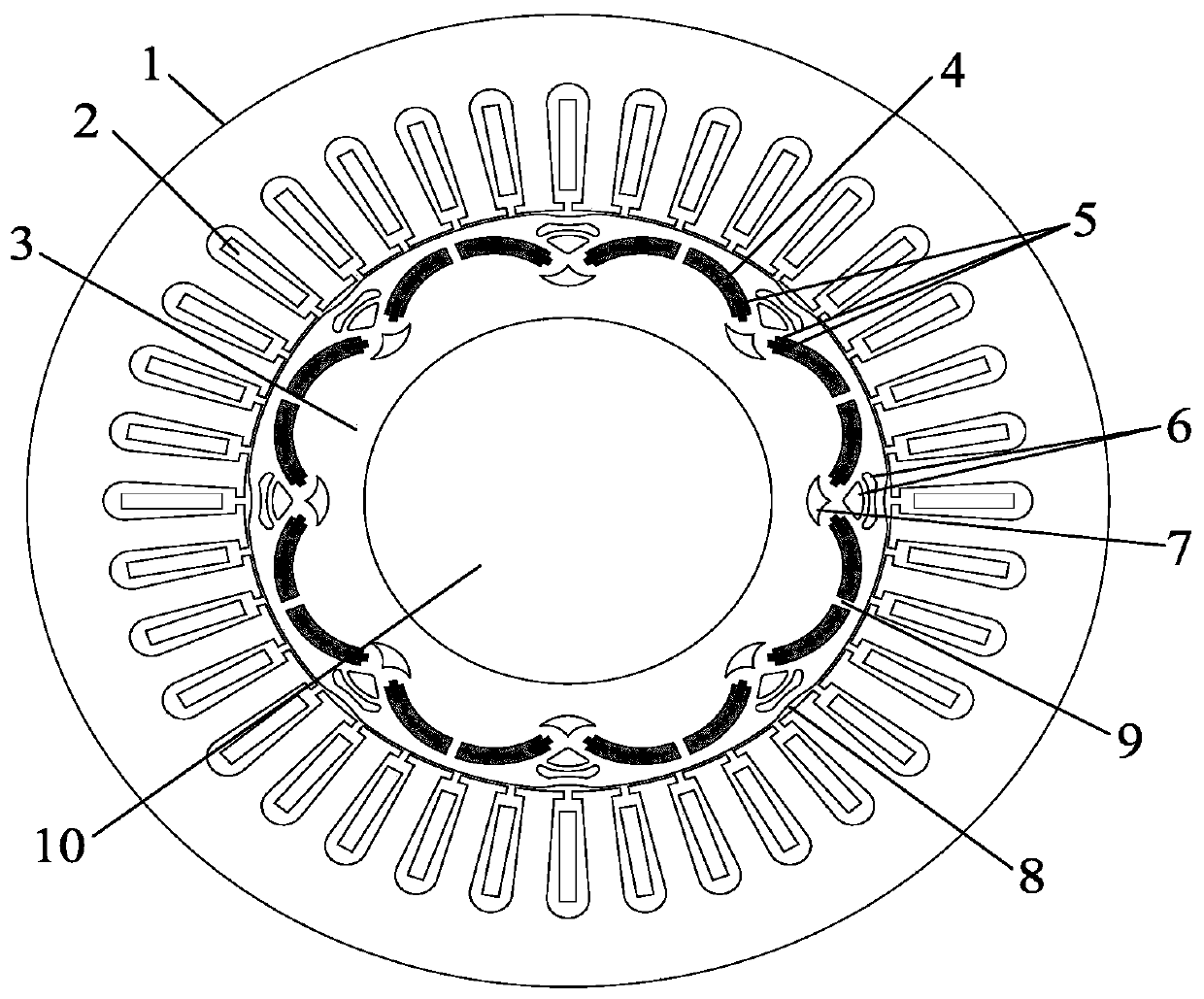

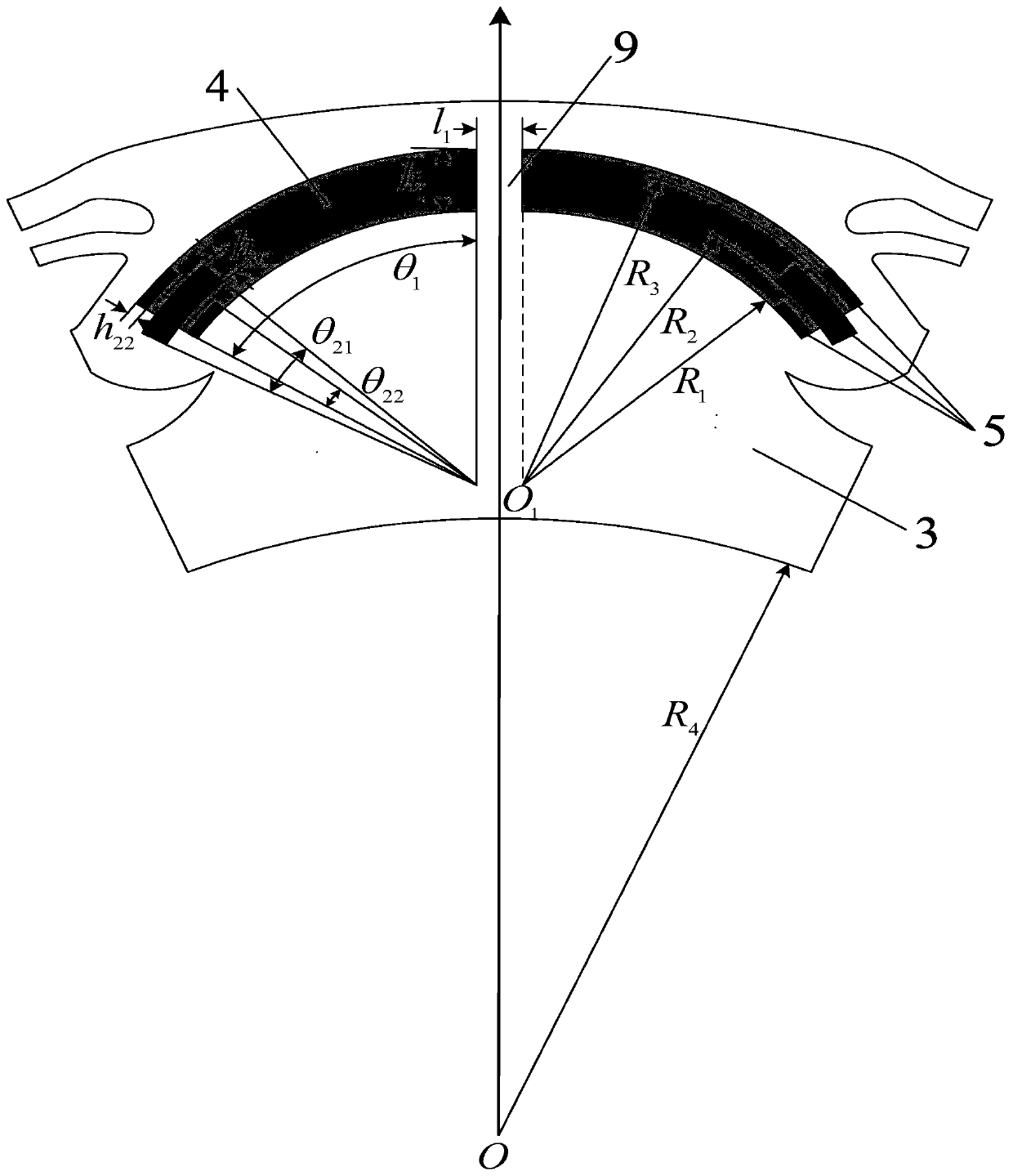

[0031] see figure 1 , the present invention includes a stator core 1 , an armature winding 2 , a rotor core 3 and a rotating shaft 10 . The outermost part is the stator core 1 , the rotor core 3 is located inside the stator core 1 , and the center of the rotor core 3 is slotted for placing the rotating shaft 10 . There is an air gap between the inner wall of the stator core 1 and the outer wall of the rotor core 3, and the thickness of the air gap is related to the power level of the motor, the mixed permanent magnet material, and the processing and assembly processes of the stator core 1 and the rotor core 3. The stator core 1 and the rotor core 3 are formed by laminating silicon steel sheets of the same thickness, the lamination thickness is 0.35 mm, and the lamination coefficient is 0.95. The shaft 10 is made of non-magnetic material.

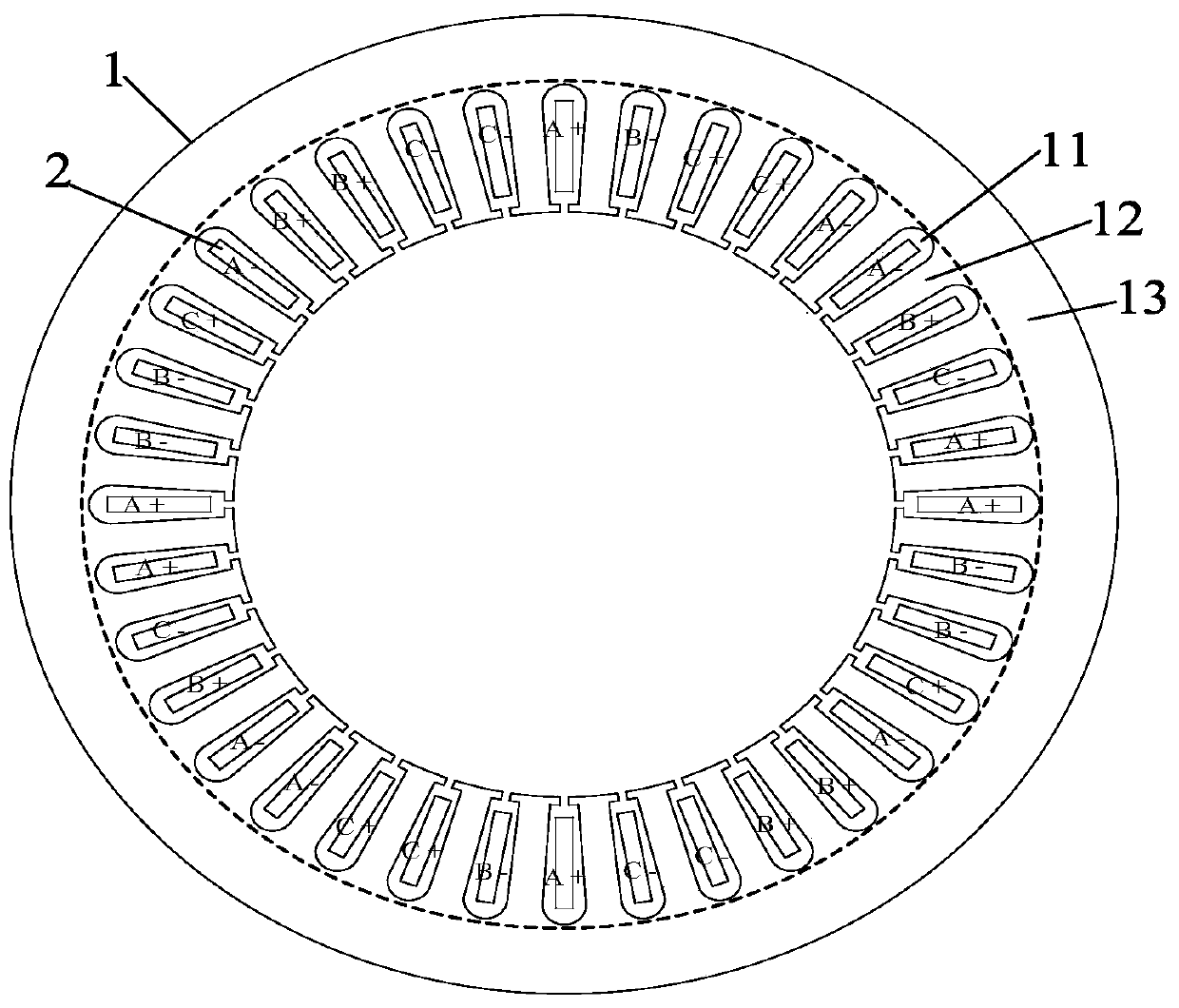

[0032] see figure 2 , The stator core 1 is composed of a stator slot 11 , a stator tooth 12 and a stator yoke 13 . The inner wall of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com