Cartilage slicer for plastic surgery

A slicer, cartilage technology, applied in bone implants, medical science, prosthesis, etc., can solve the problems of cartilage drop, deflection, splitting, slow operation, etc., and achieve the effect of uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

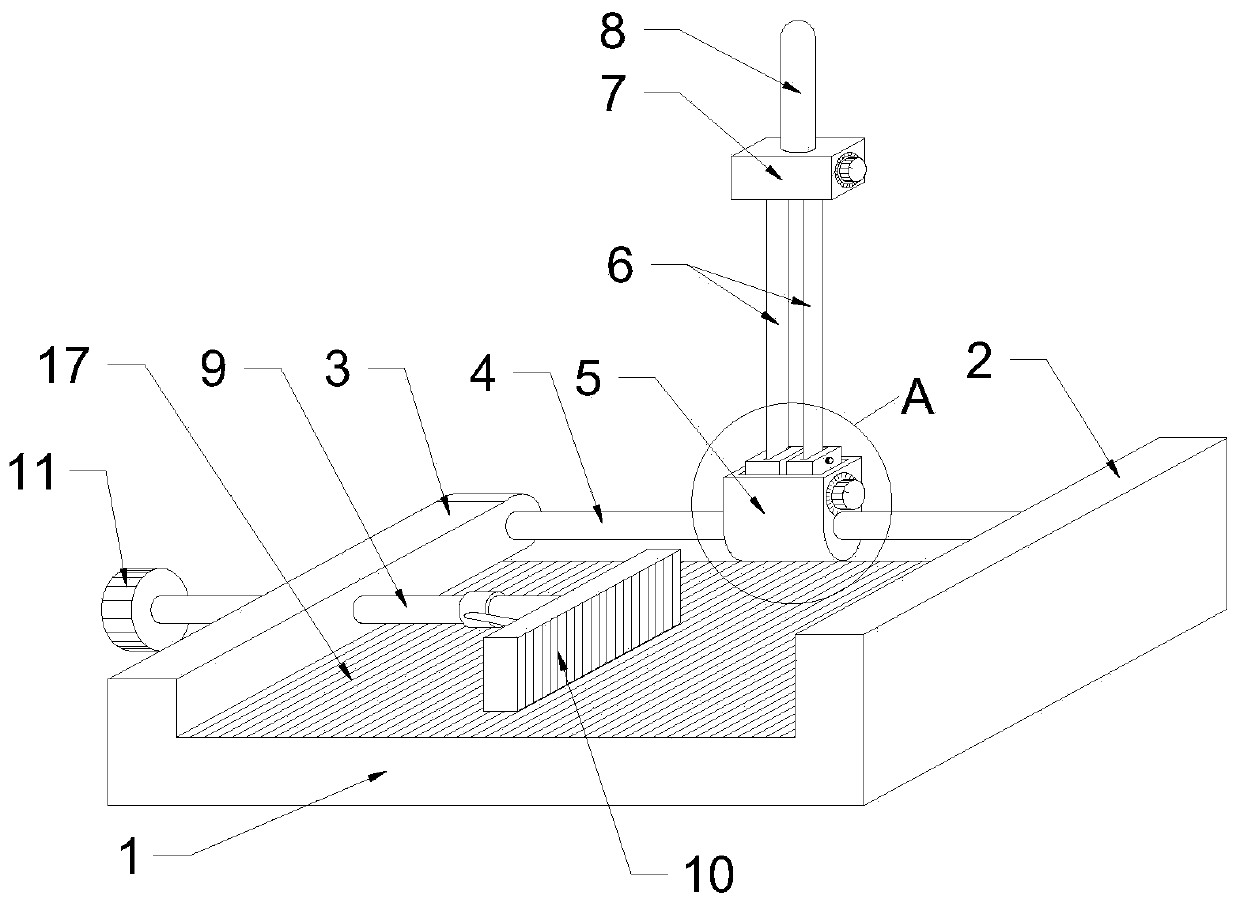

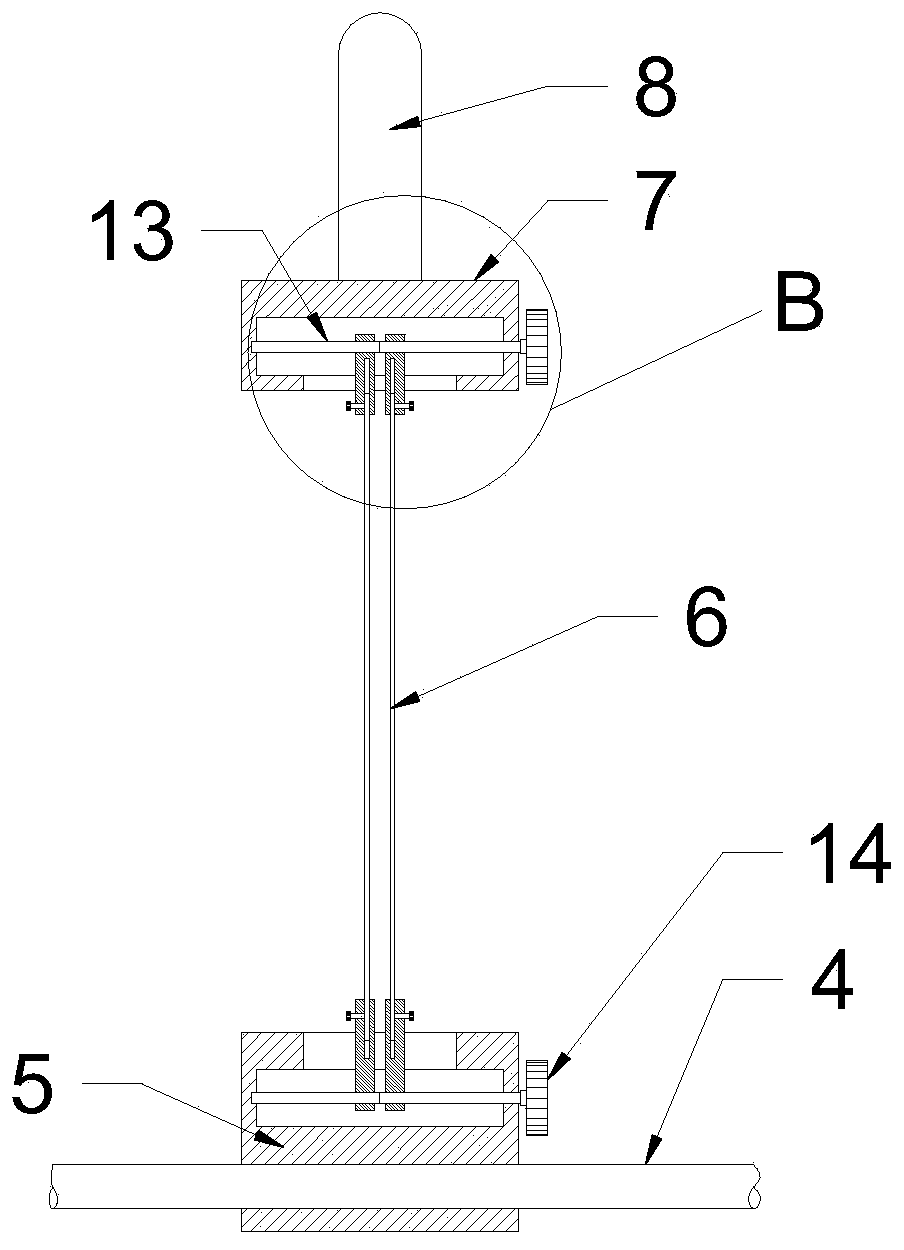

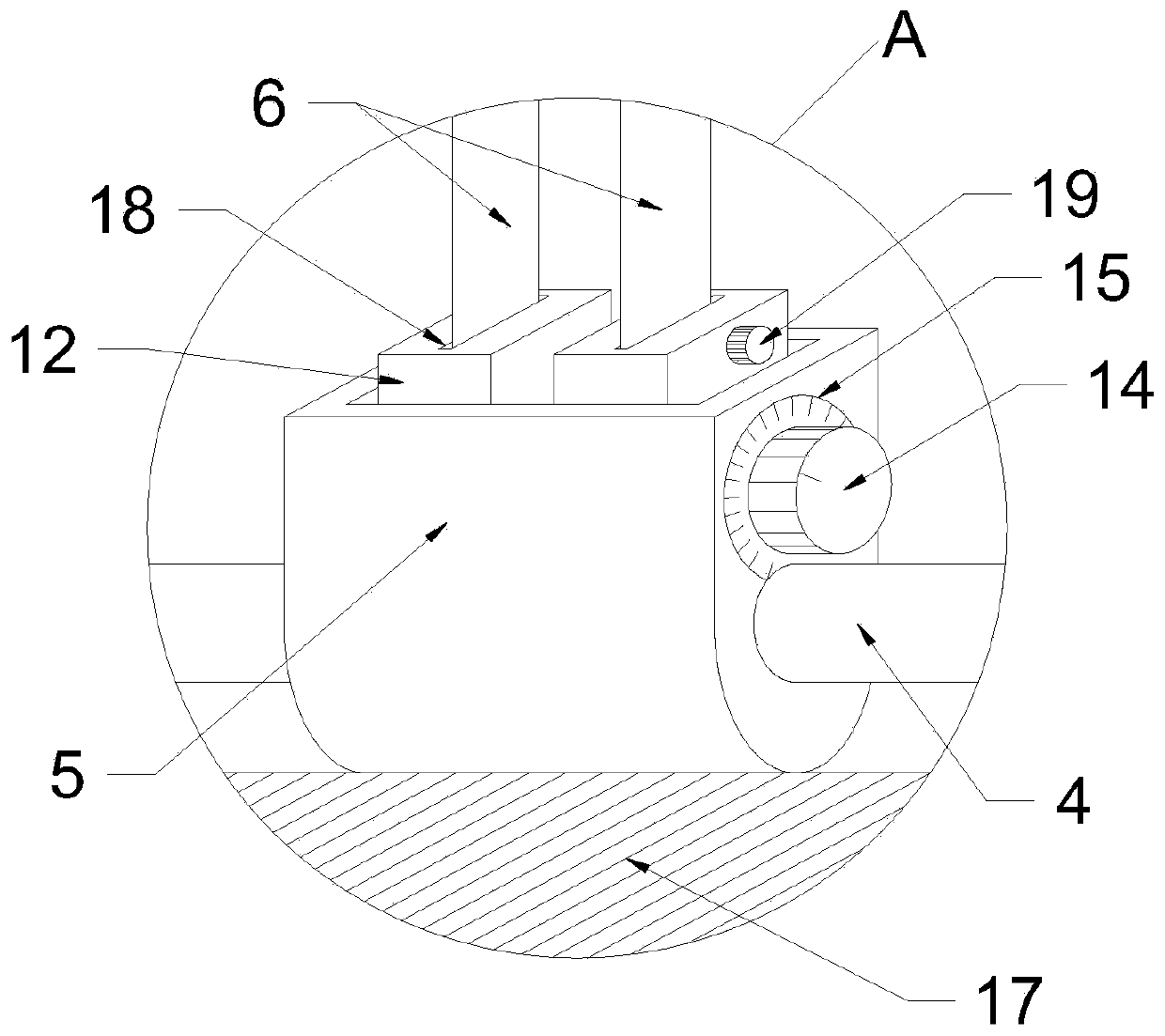

[0024] see Figure 1-5 , a cartilage slicer for plastic surgery, comprising a base plate 1, the upper surface of the base plate 1 is oppositely provided with a stopper 2 and a fixed block 3 parallel to each other, a slide bar 4 is arranged between the stop block 2 and the fixation block 3, and the slide bar 4 Respectively perpendicular to the block 2 and the fixed block 3; the slide bar 4 is pierced with a slide block 5, and the slide block 5 is equipped with two blades 6 whose blades can be attached to the upper surface of the bottom plate 1, and the two blades 6 are Parallel to the block 2; the ends of the two blades 6 away from the slider 5 are all installed on the connecting block 7, and the connecting block 7 is provided with a rotating handle 8; the fixed block 3 is provided with threaded holes, and the fixed block 3 The threaded hole is pierced with an adjusting screw 9 that matches the threaded hole. The end of the adjusting screw 9 located between the block 2 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com