A waste solid waste treatment device with waste gas treatment function

A waste treatment device and waste gas treatment technology, which is applied in biological organic part treatment, grain treatment, solid waste removal, etc. The problem of slow molding of biological fertilizers, etc., achieves the effect of fast and convenient use, safe and convenient use, and convenient replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

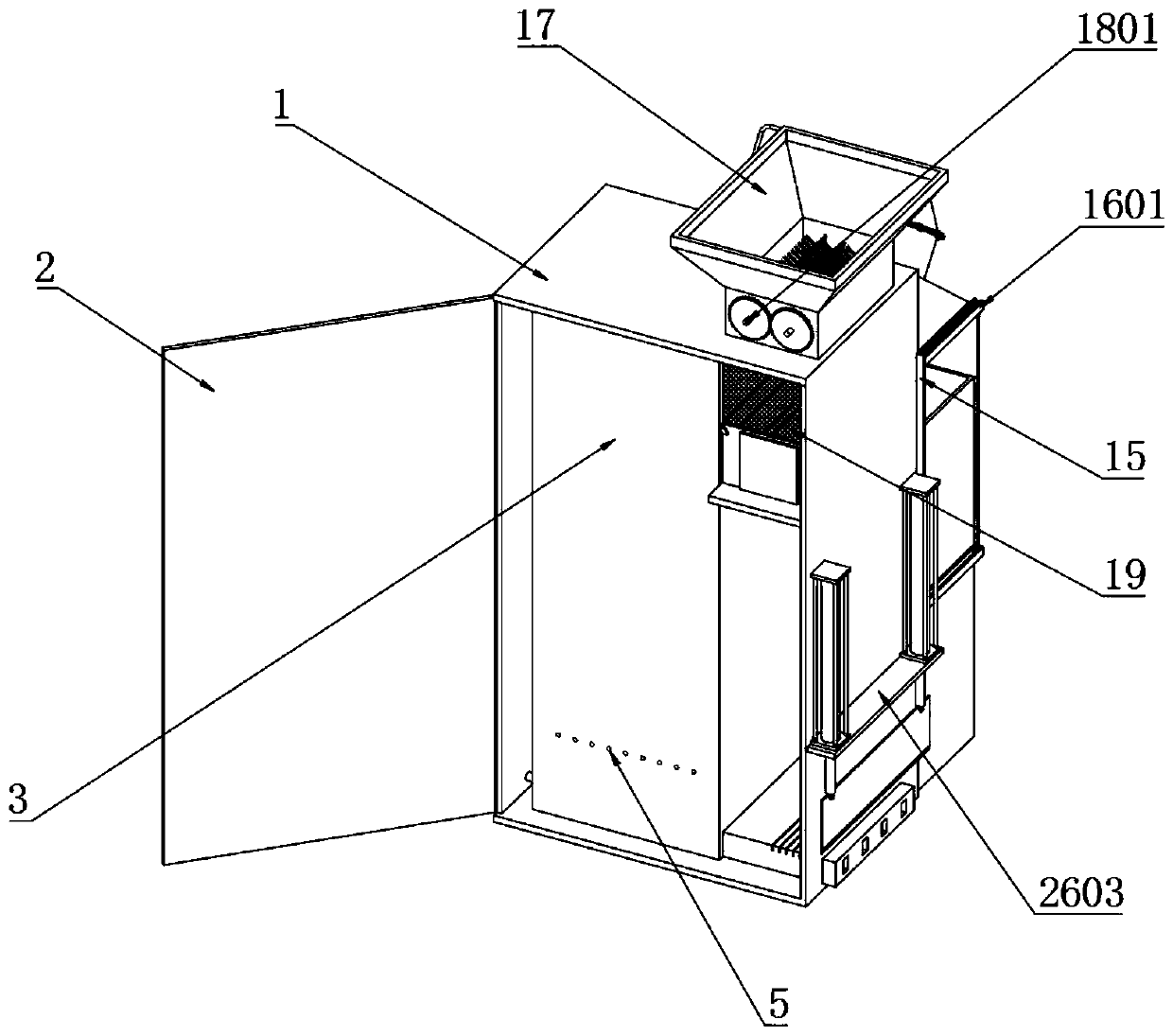

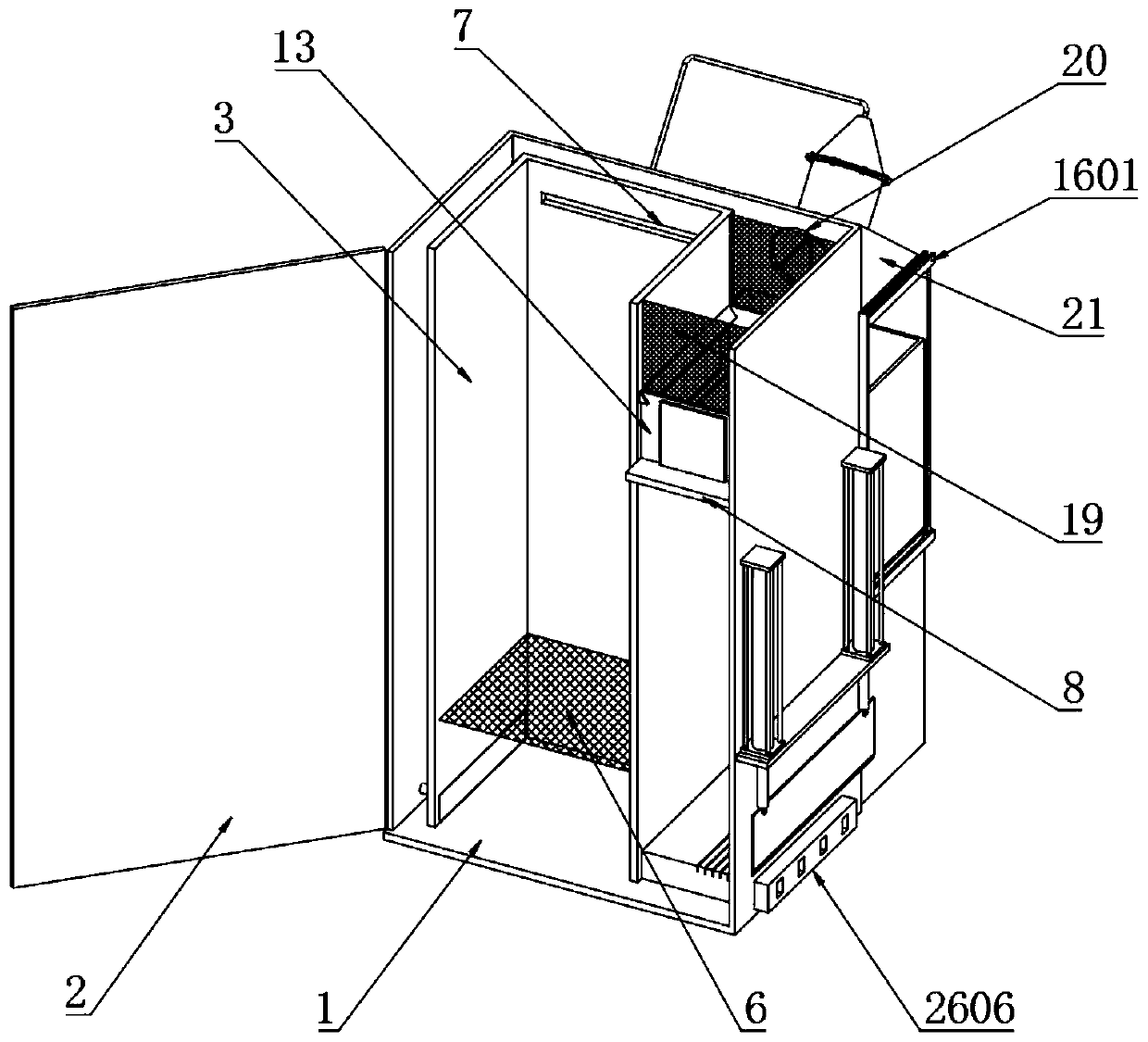

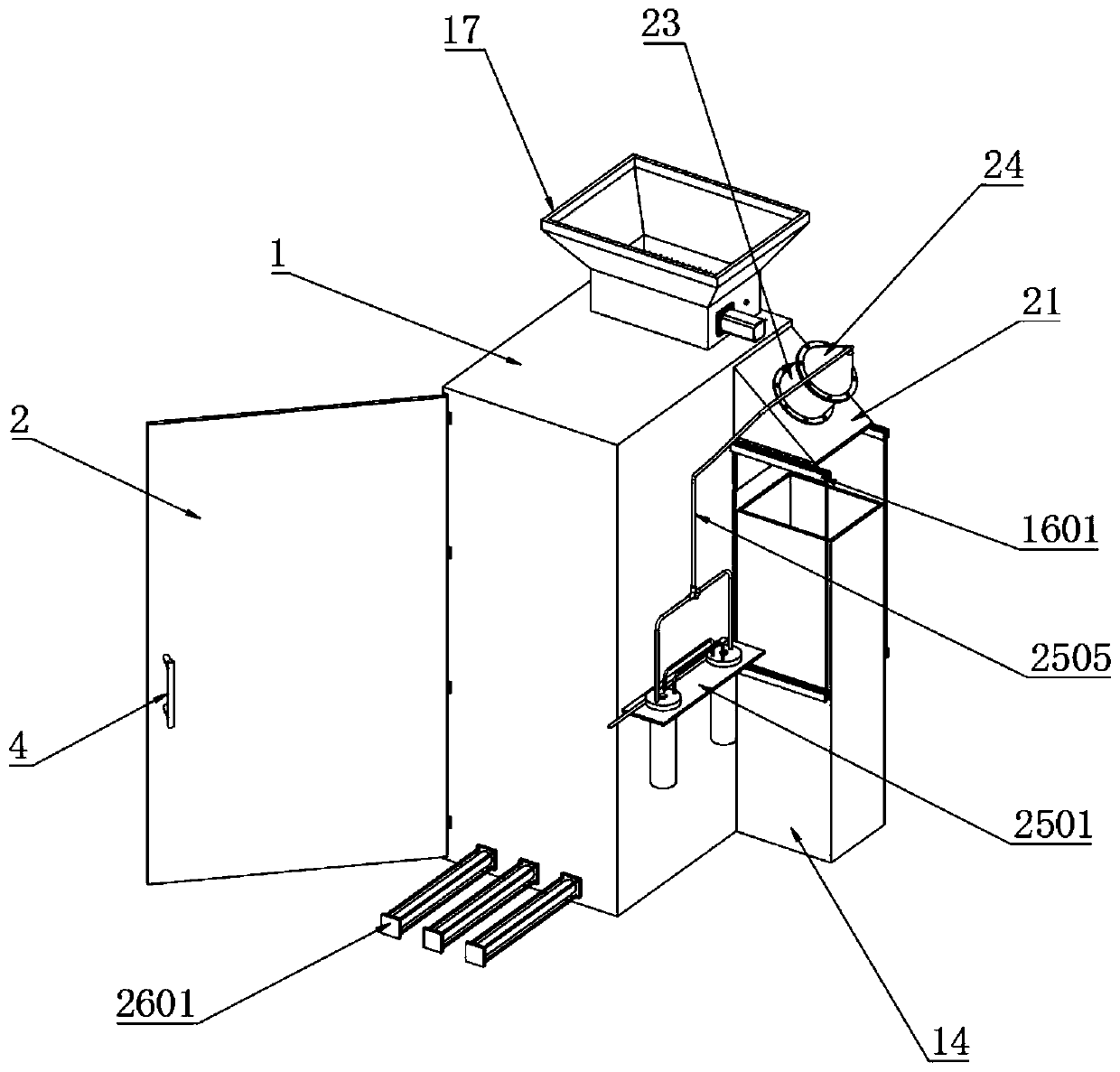

[0049] Example: such as Figure 1-9 As shown, the present invention provides a technical solution, a waste solid waste treatment device with a waste gas treatment function, comprising a main box body 1, a box door 2 hinged on the front edge of the main box body 1, and one side of the box door 2 A handle 4 is welded in the middle of the surface, an incineration box 3 is built at the inner bottom of the main box body 1, and a number of air inlet holes 5 are equidistantly penetrating through the bottom of the front end of the incineration box 3, through which the igniter can pass through the air inlet holes 5 to waste gas. The solid waste is ignited, and the top of the back end of the incineration box 3 is provided with an exhaust groove 7, and the interior of the incineration box 3 is equipped with a partition frame 6 at the position below the corresponding exhaust groove 7;

[0050] The top of the side end surface of the incineration box 3 is provided with a feed inlet 10, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com