Automatic pipeline damping manufacturing device and automatic pipeline damping manufacturing method

A technology for making devices and pipes, used in manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of difficulty in mass production, time-consuming and laborious, and it is difficult to ensure consistency and interchangeability, so as to ensure accuracy and consistency. The effect of high performance and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

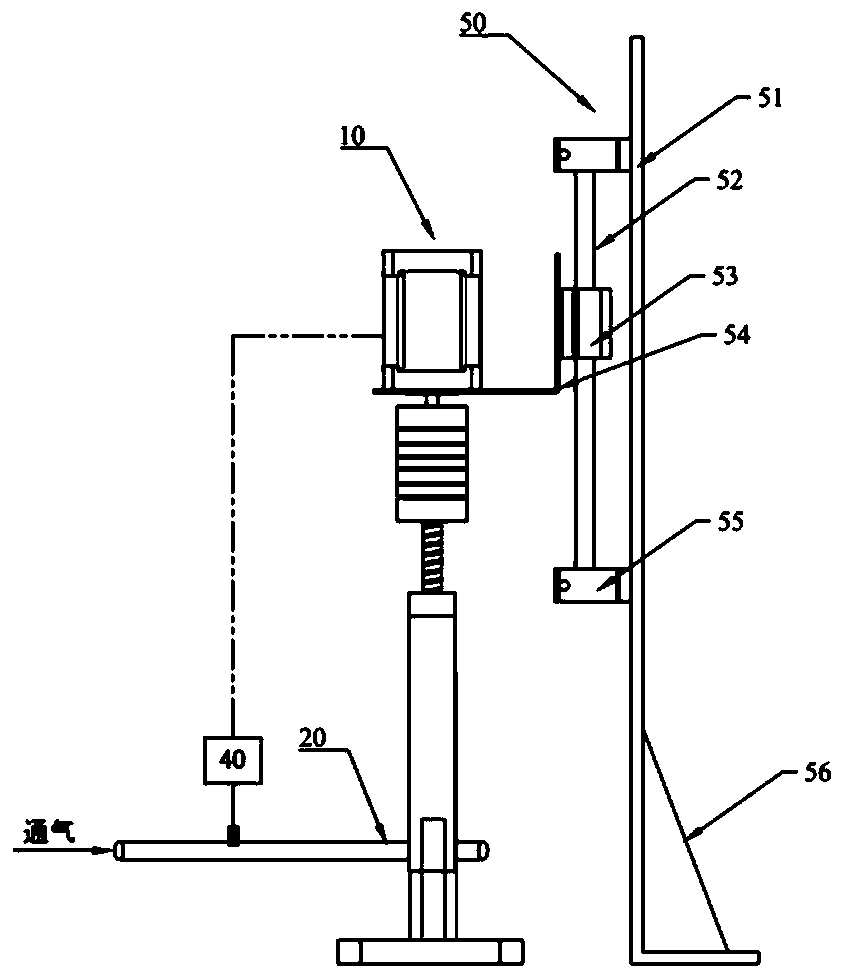

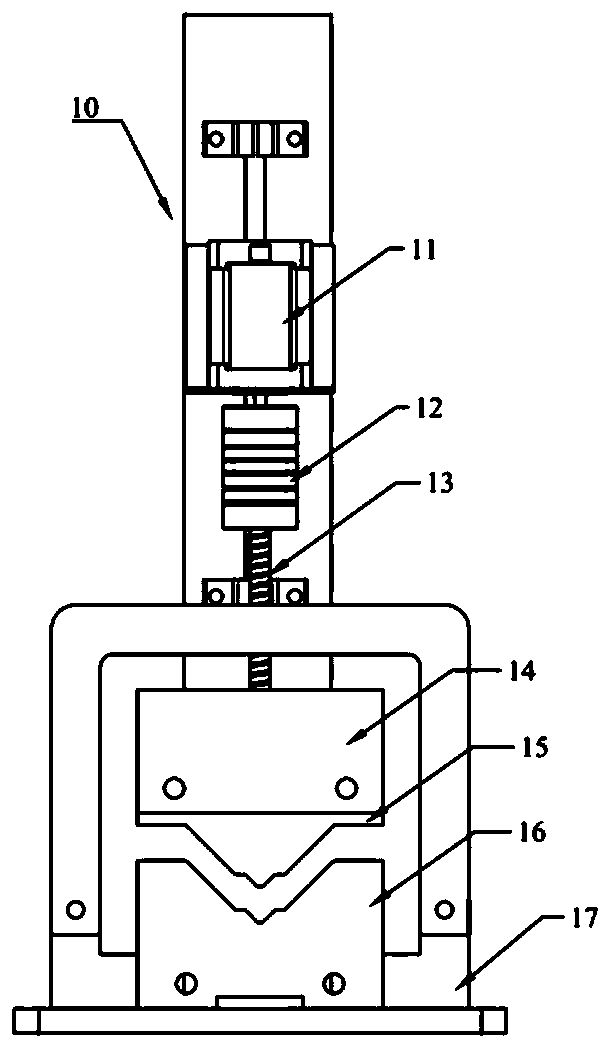

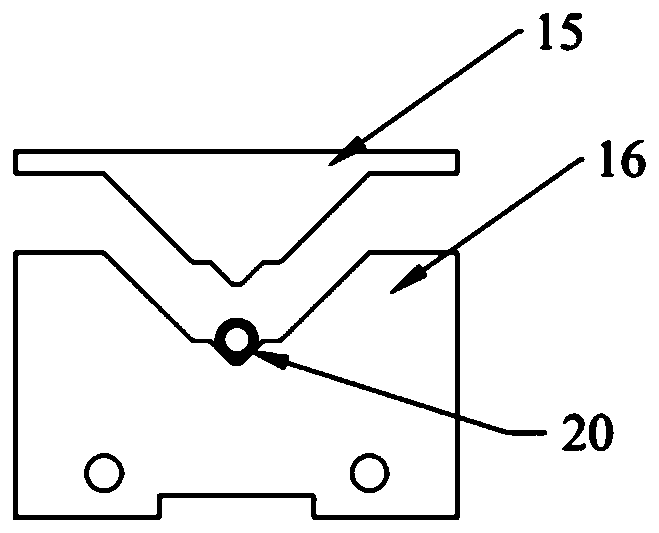

[0034] Such as Figure 1-4 As shown, the pipeline damping automatic manufacturing device provided in this embodiment includes a driving mechanism 10, an upper pressing block 15, a lower pressing block 16 and a gas flow meter 40, the lower pressing block 16 is provided with a pipeline processing groove, and the upper pressing block 15 is provided with a pressing Protrusion; gas flowmeter 40 is arranged on pipeline 30 to be made damping, and one side of pipeline 30 is ventilated; Gas flowmeter 40 is electrically connected to driving mechanism 10, and pipeline 30 stretches in the pipeline processing groove of lower pressing block, and is positioned at At a damping point, the driving mechanism 10 drives the upper pressing block 15 to move downward, and the pressing protrusion of the lower pressing block 16 presses the pipeline downward until the gas flow meter 40 reaches the required flow value, and the driving mechanism 10 stops.

[0035] The drive mechanism 10 used in this embod...

Embodiment 2

[0041] This embodiment also provides a method for automatically producing pipeline damping, using the automatic pipeline damping production device described in Embodiment 1, including at least the following steps:

[0042] S1, connect the pipeline to be damped to the gas measuring instrument, and ventilate on one side of the pipeline;

[0043]S2, extending the pipeline to be damped into the pipeline processing groove of the lower pressing block, and positioning it to a damping production point;

[0044] S3, the driving mechanism drives the upper pressing block to move downward, and the pressing protrusion of the upper pressing block presses the pipeline downward until the gas flowmeter reaches the required flow rate, the driving mechanism stops;

[0045] S4, setting a limiting block in the limiting groove between the upper pressing block and the lower pressing block;

[0046] S5, moving the pipeline to put another damping point into the pipeline processing groove of the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com