Tenon pushing and embedding intelligent flexible assembling line based on lining plate sliding attaching splicing

An assembly line and mortise and tenon technology, which is applied in the field of intelligent flexible assembly lines, can solve problems such as broken plates, surge of pushing force, and deviation of plate inclinations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

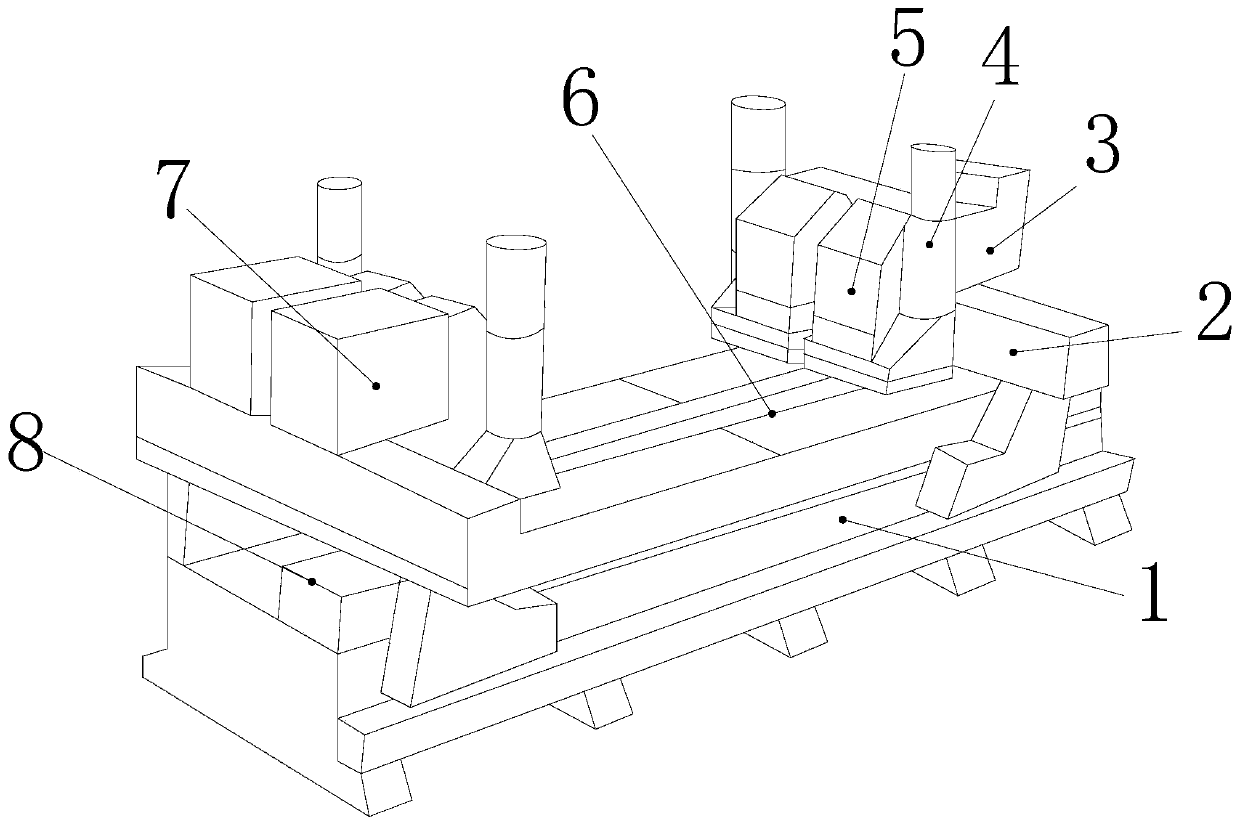

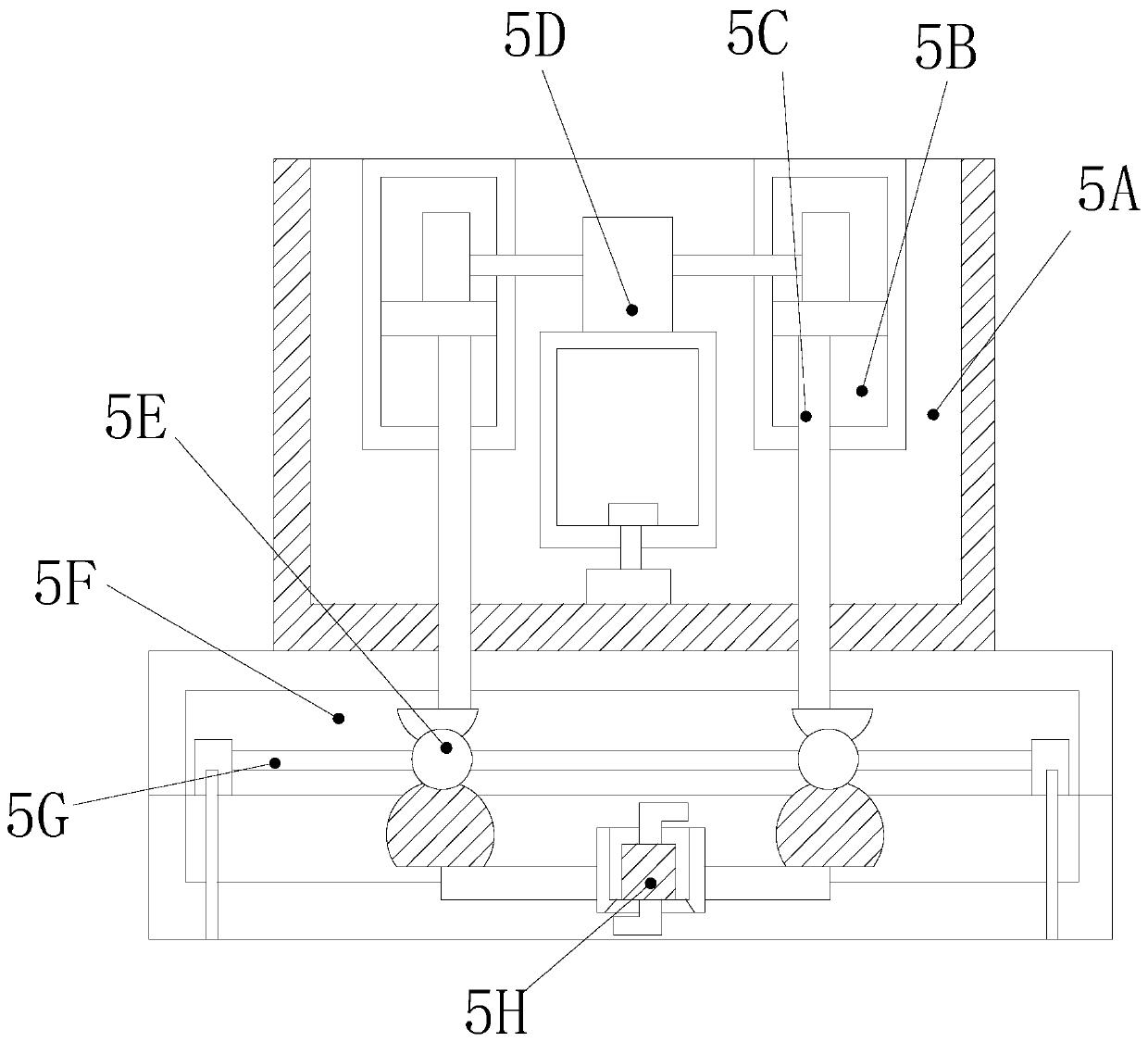

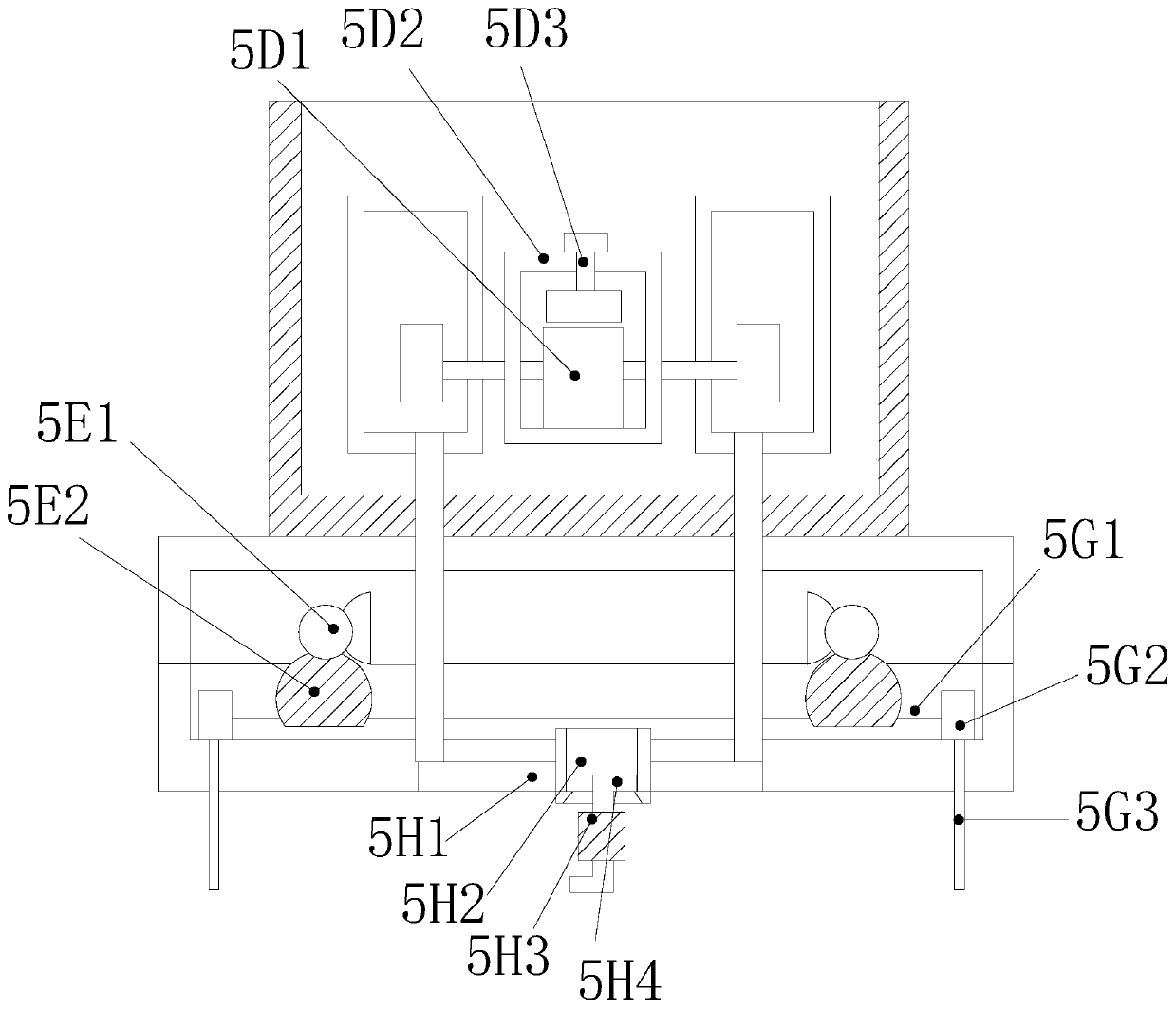

[0033] see Figure 1-Figure 7 , the present invention provides an intelligent flexible assembly line for pushing and tenoning parts based on the sliding assembly of lining boards. Tenon assembling mechanism 5, working table 6, hydraulic tank 7, track pad 8, said tenon assembling mechanism 5 is closely attached to pneumatic column tube 4 and interpenetrated with each other, and said tenon assembling mechanism 5 passes through the rack The buckle block 3 and the arch slide 2 are buckled together and are perpendicular to each other, the groove base 1 is mechanically connected with the arch slide 2 through the track pad block 8, and the worktable 6 is installed on the track pad On the top of the block 8 and on the same horizontal plane, the hydraulic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com