Wood-plastic composite surface texture shaping device

A wood-plastic composite material and shaping device technology, which is applied to the device for coating liquid on the surface, decorative art, special patterns, etc., can solve the problems of wasting manpower, slow work speed, and low work efficiency, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] see Figure 1-8 , the present invention provides a technical solution:

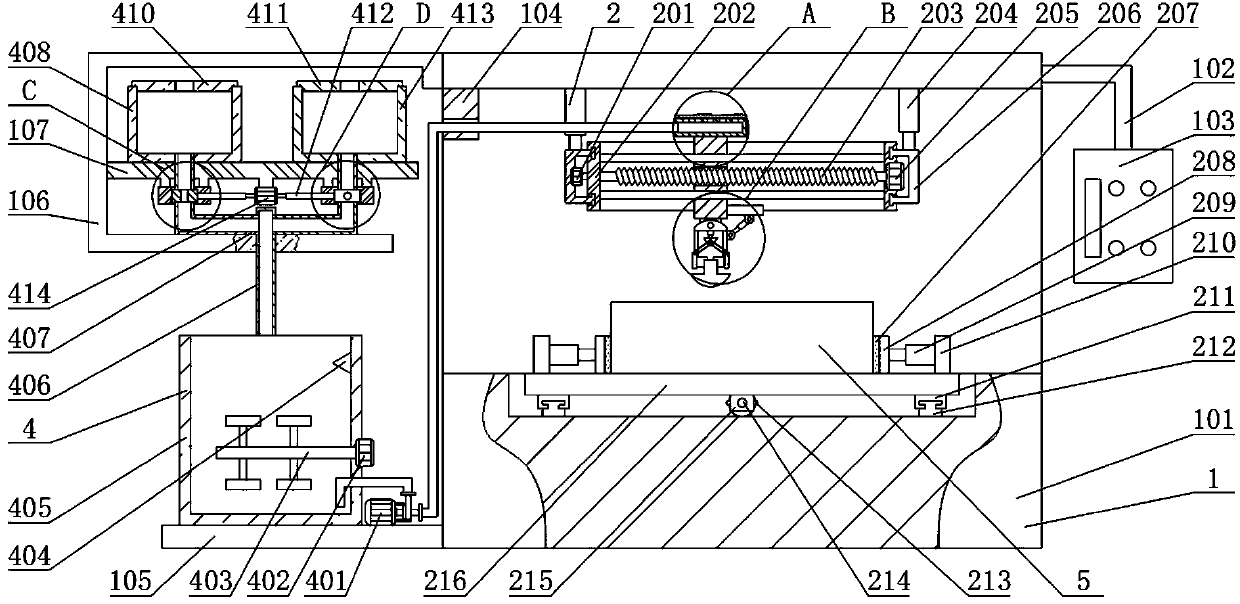

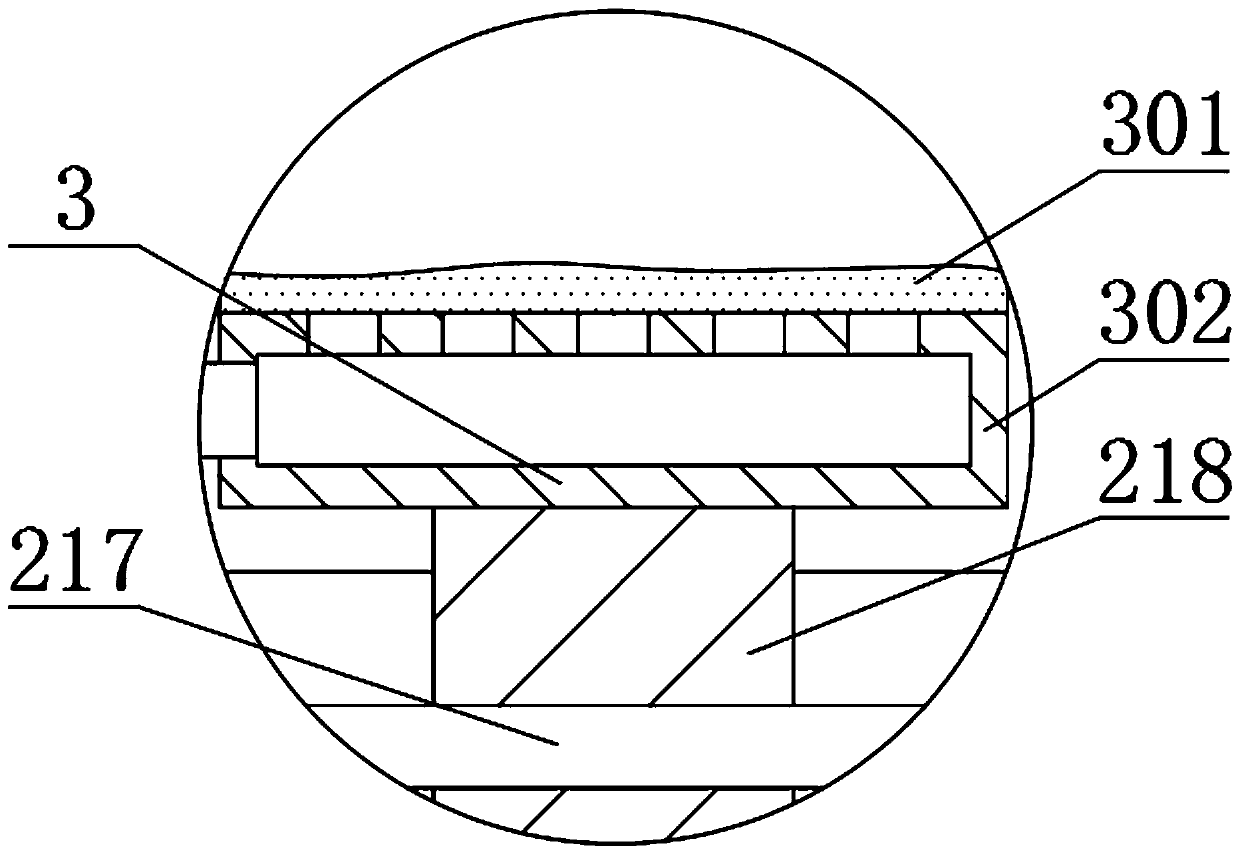

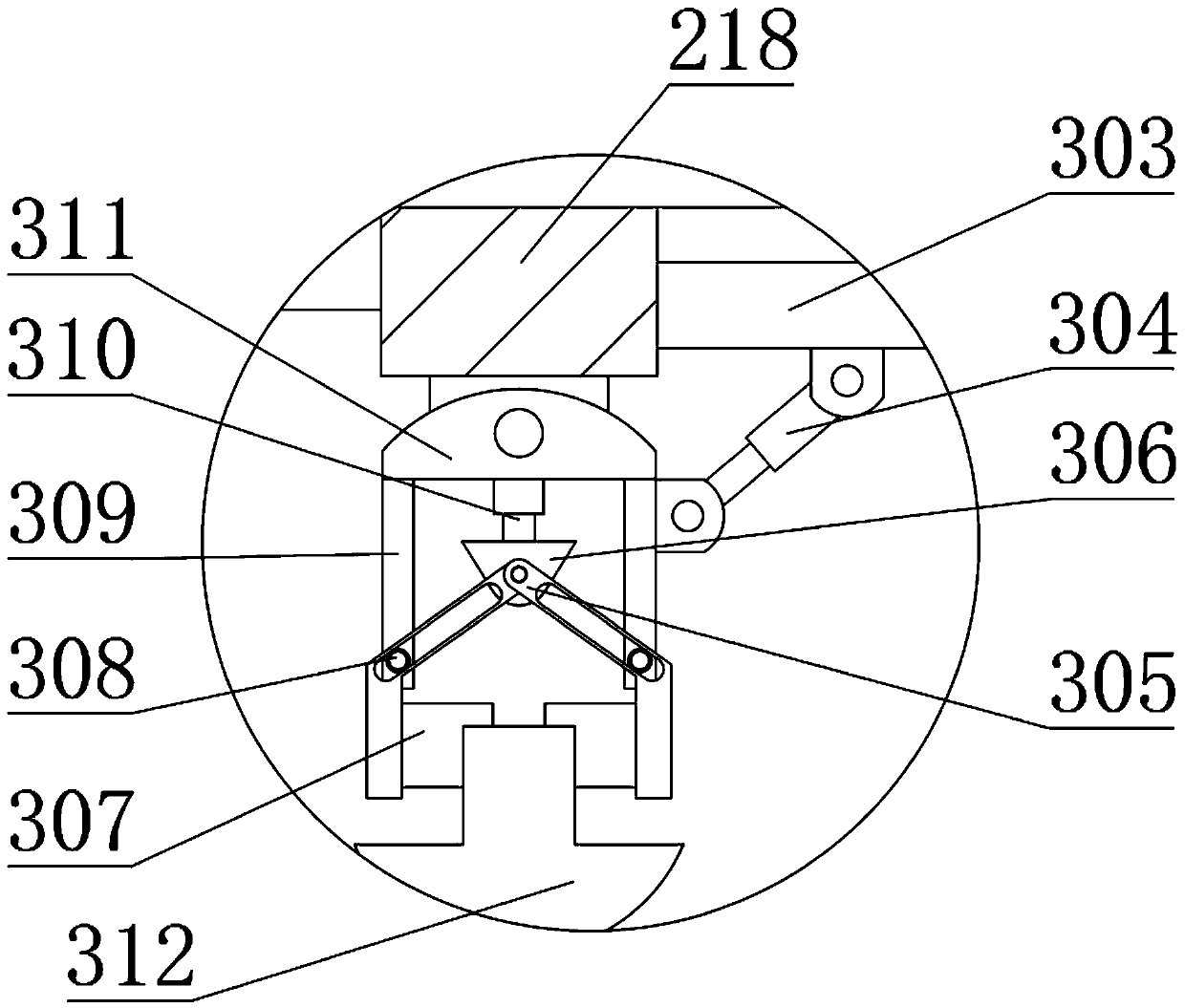

[0029]A wood-plastic composite material surface texture shaping device, comprising a main body device 1, an adjustment device 2, a texture shaping device 3, a dynamic balance device 4 and a wood-plastic composite material plate 5, one end of the main body device 1 is fixedly connected with the adjustment device 2, and the adjustment One end of the device 2 is fixedly connected with a texture shaping device 3, the left end of the main device 1 is fixedly connected with a dynamic balance device 4, and one end of the adjustment device 2 is provided with a wood-plastic composite board 5, and the main device 1 includes a base 101, a connecting rod 102, a control Cabinet 103, connection plate 104, support plate 105, fixed frame 106 and fixed plate 107, one end of dynamic balance device 4 is fixedly connected with base 101, the left end of base 101 is fixedly connected with support plate 105, the right en...

Embodiment 2

[0033] see Figure 1-8 , the present invention provides a technical solution:

[0034]A wood-plastic composite material surface texture shaping device, comprising a main body device 1, an adjustment device 2, a texture shaping device 3, a dynamic balance device 4 and a wood-plastic composite material plate 5, one end of the main body device 1 is fixedly connected with the adjustment device 2, and the adjustment One end of the device 2 is fixedly connected with a texture shaping device 3, the left end of the main device 1 is fixedly connected with a dynamic balance device 4, and one end of the adjustment device 2 is provided with a wood-plastic composite board 5, and the main device 1 includes a base 101, a connecting rod 102, a control Cabinet 103, connection plate 104, support plate 105, fixed frame 106 and fixed plate 107, one end of dynamic balance device 4 is fixedly connected with base 101, the left end of base 101 is fixedly connected with support plate 105, the right en...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap