Quantitative candy taking candy jar

A candy and can body technology, which is applied in the field of quantitatively taking sugar candy cans, can solve the problems of simple structure of the can body, contamination of candy, and contaminants brought into the can, and achieves the effects of convenient use, safe and hygienic use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

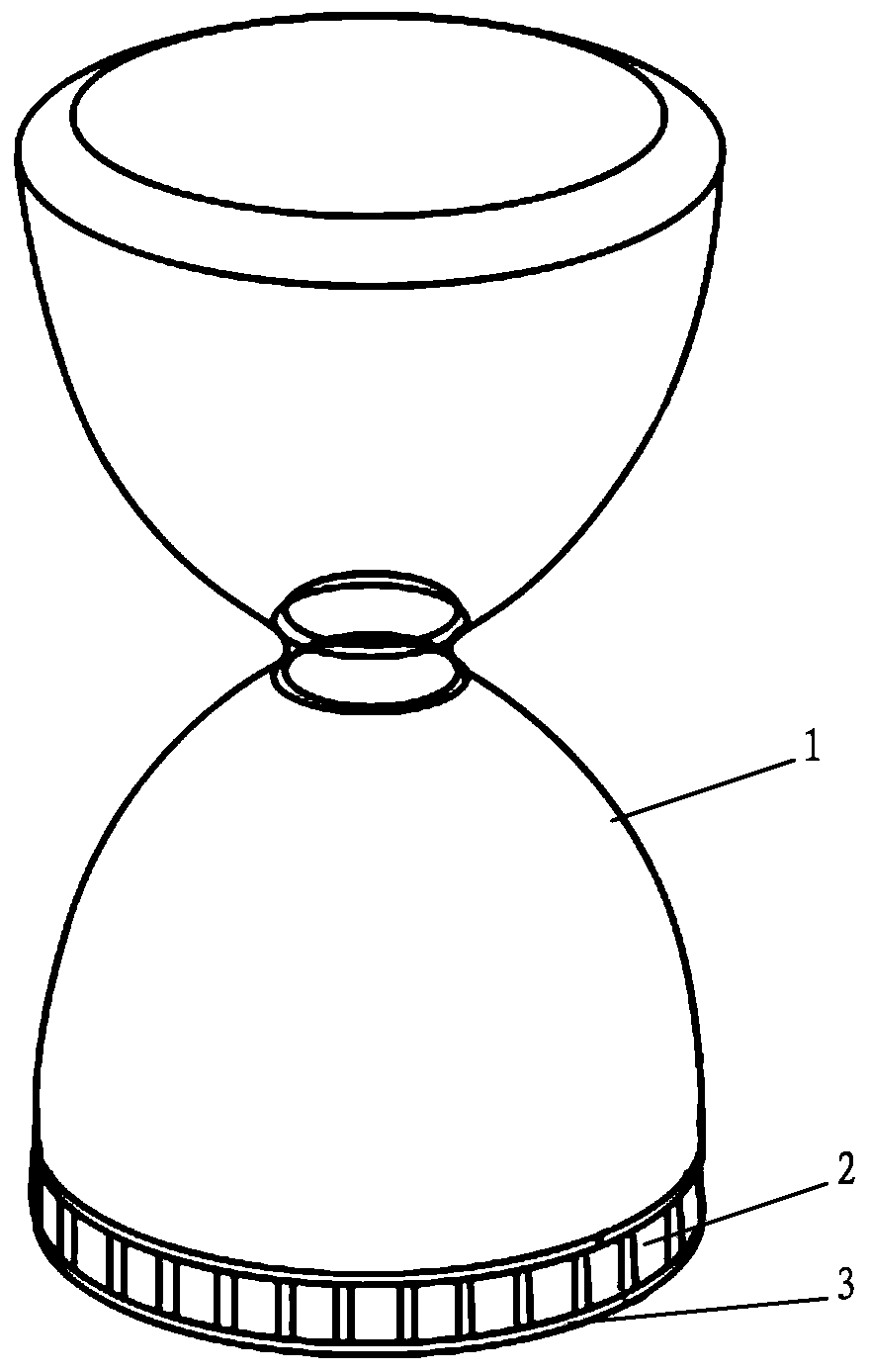

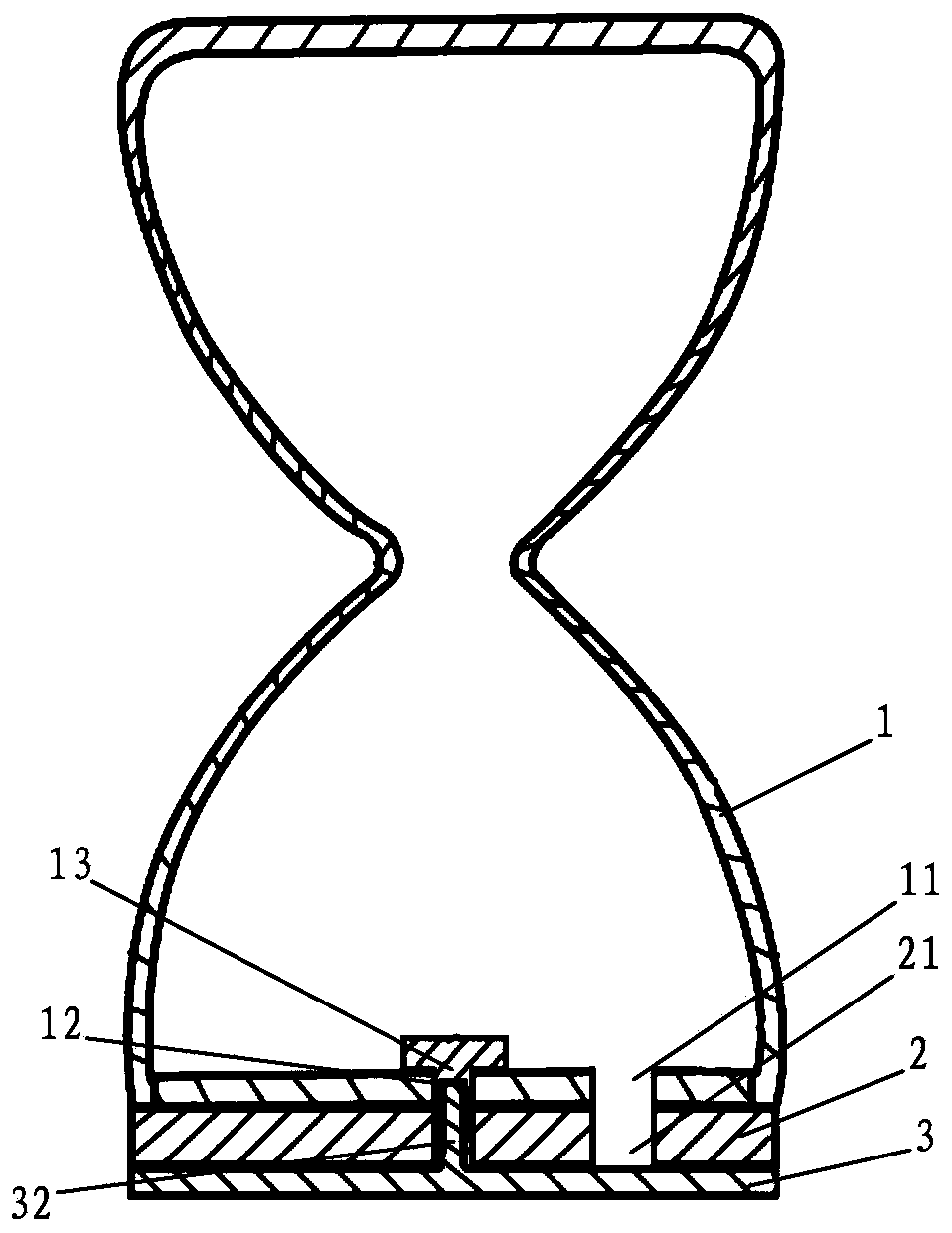

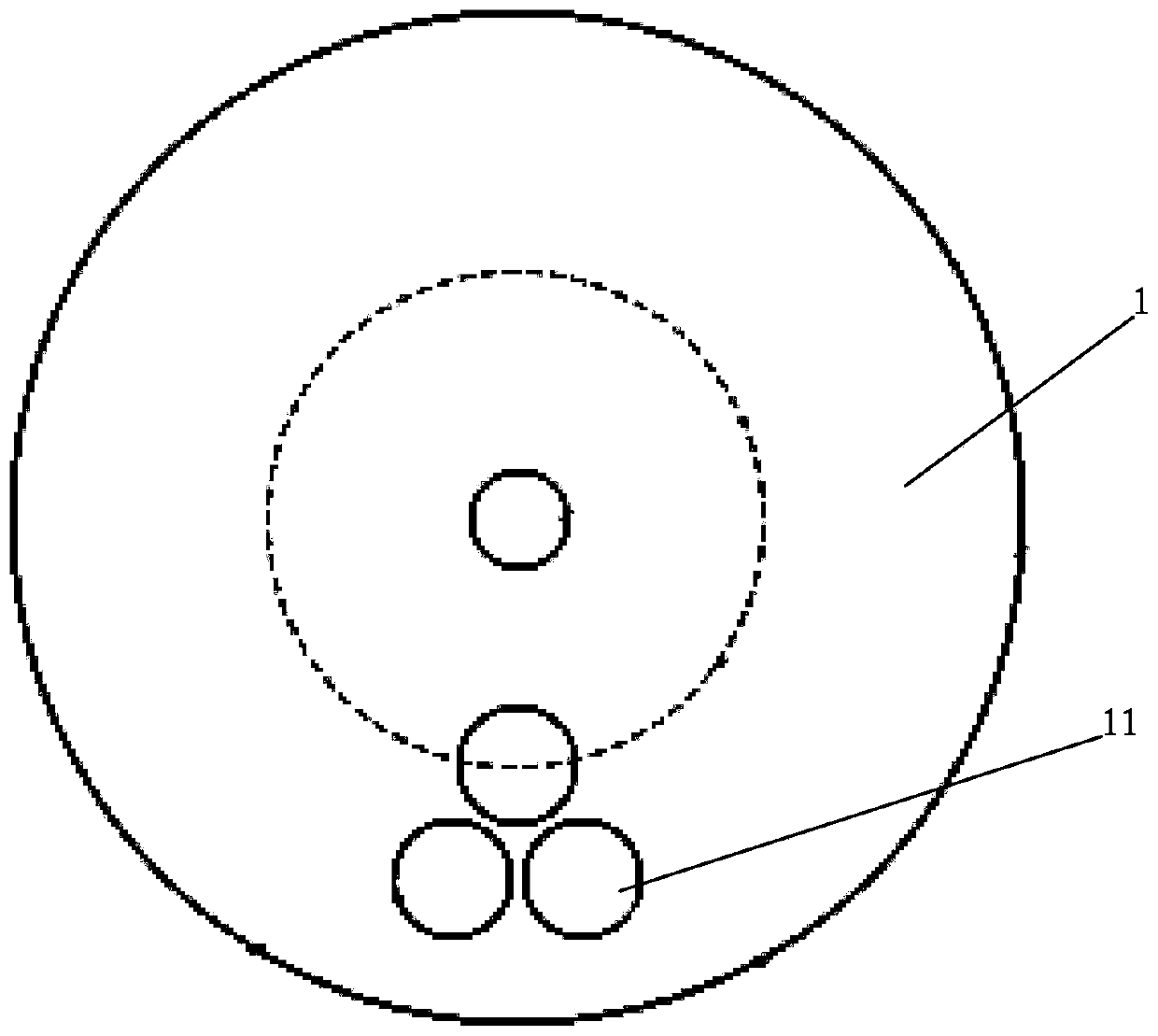

[0024] Reference Figure 1 to Figure 5 , This embodiment relates to a quantitative sugar candy canister, including a can body 1, a storage turntable 2 and a sugar outlet baffle 3, the storage turntable 2 is rotatably mounted on the bottom end of the can body 1, the sugar outlet baffle 3 It is rotatably mounted on the bottom end of the storage turntable 2; the bottom end of the tank body 1 is provided with a first outlet 11, and the storage turntable 2 is provided with a second outlet 21 corresponding to the first outlet 11, The sugar outlet baffle 3 has a third outlet 31 corresponding to the second outlet 21; the second outlet 21 can store a set amount of candies, and the storage carousel 2 rotates to the second outlet 21 and When the first outlet 11 is connected, the candies in the tank 1 fall from the first outlet 11 to the second outlet 21, and then rotate the storage turntable 2 to separate the second outlet 21 from the first outlet 11, and the sugar outlet baffle 3 When r...

Embodiment 2

[0035] This embodiment is based on implementation 1, as an improvement to the connection structure between the tank body 1, the storage turntable 2 and the sugar outlet baffle 3, the bottom center of the tank body 1 and the center of the storage turntable 2 are open In the hole 12, a rotating shaft 32 is provided in the center of the sugar outlet baffle 3, the storage turntable 2 is rotatably sleeved on the rotating shaft 32, and the rotating shaft 32 is rotatably sleeved in the through hole 12 of the tank body 1. The rotating shaft 32 and the through hole 12 are connected by interference fit or transition fit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com