Assembly line type material turnover equipment and assembly line type material turnover method

A flipping equipment, assembly line technology, applied in the direction of metal processing equipment, grinding/polishing equipment, conveyor objects, etc., can solve the problems that can not meet the requirements of automatic production, to reduce labor costs, high degree of automation, improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

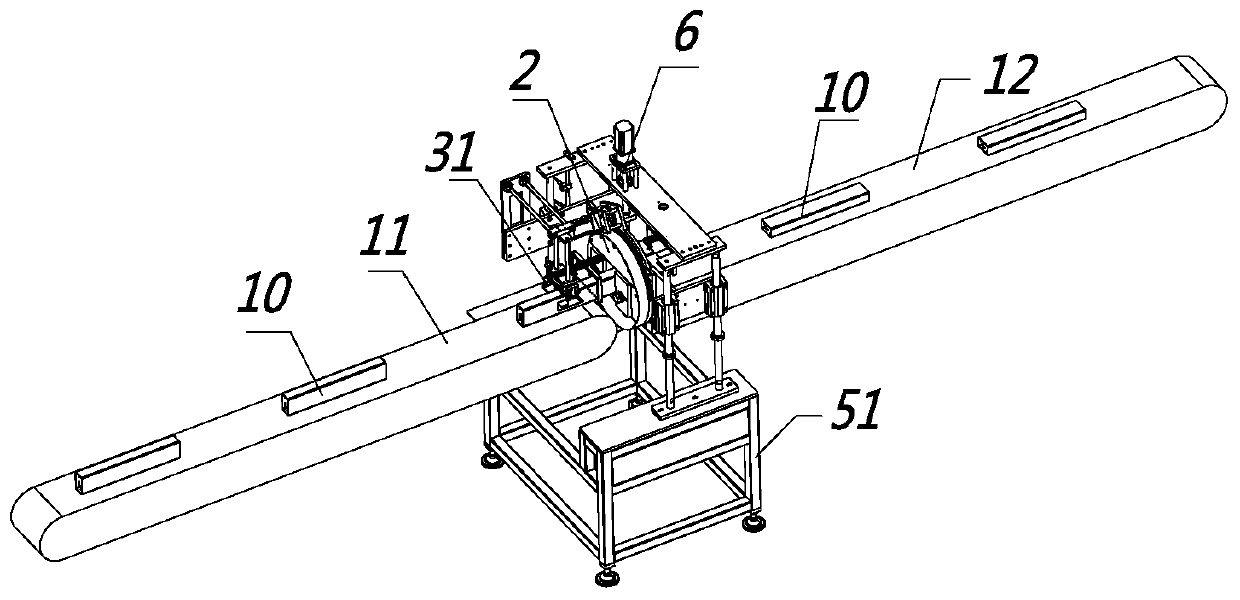

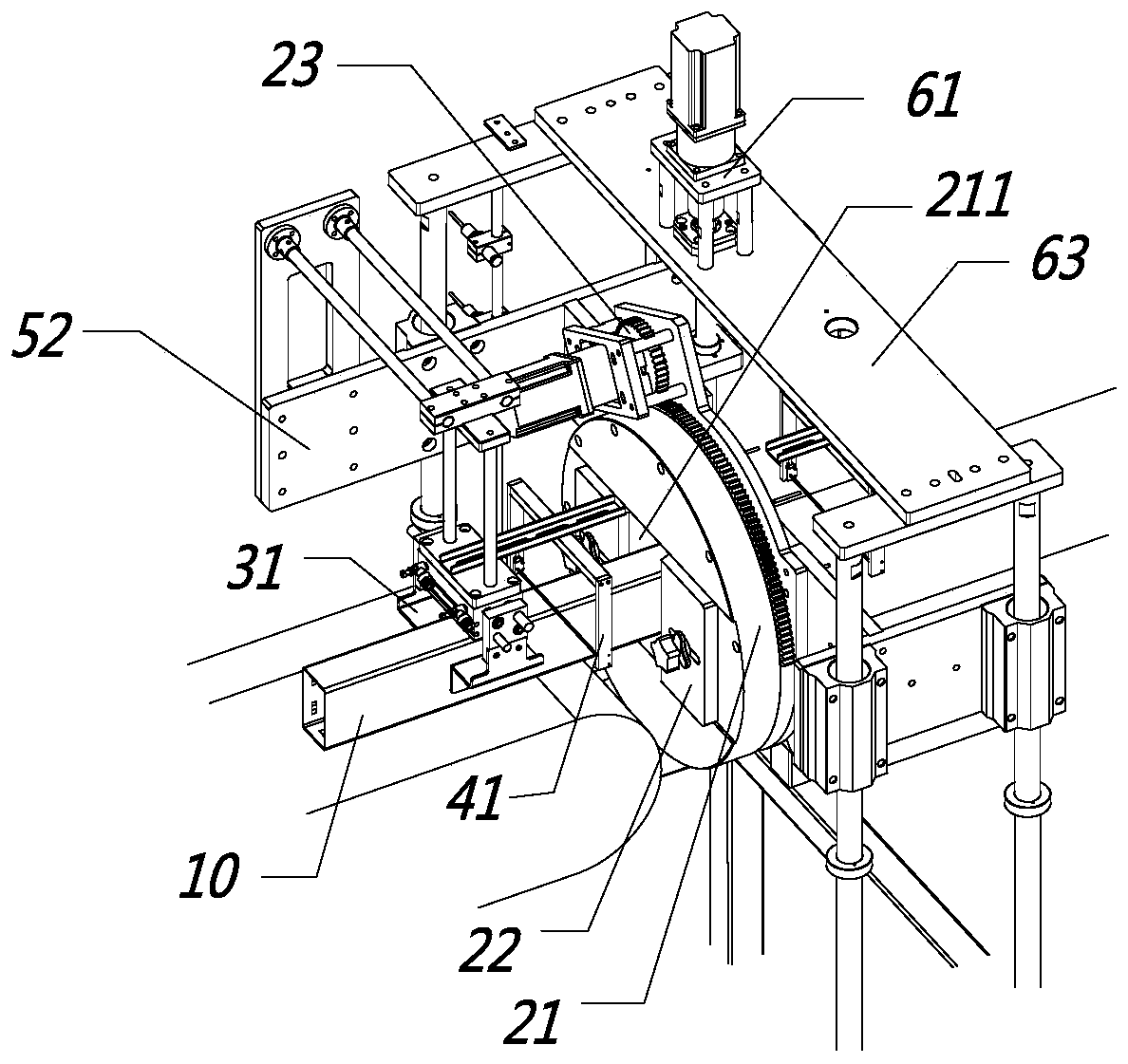

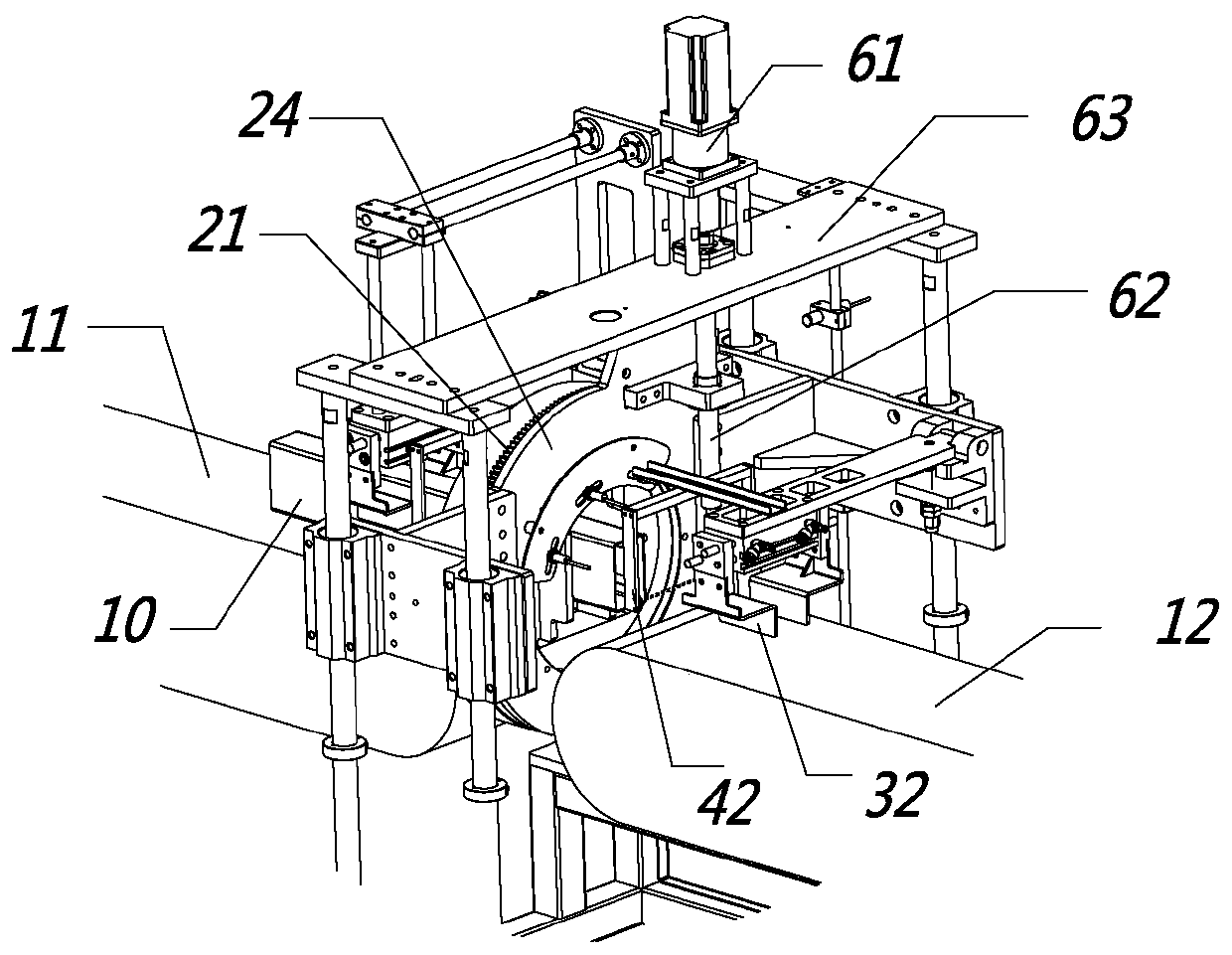

[0033] Such as Figure 1 to Figure 4 As shown, what this embodiment shows is a kind of assembly line type material turning equipment, the material 10 is transported to the processing equipment through the conveyor belt, in this embodiment the processing equipment is preferably a water mill, and the material 10 is a tubular piece, this embodiment The tubular part shown in the figure is a square tube. The four sides of the square tube in this embodiment need to be ground by a water mill to meet the surface accuracy and smoothness requirements. In the traditional grinding process, when a After one side, manual flipping and positioning are required to achieve the grinding of the other side, which is not only time-consuming and labor-intensive.

[0034] For the conveyor belt, one end of the conveyor belt is the previous step process, and the other end of the conveyor belt is the next step. In the present embodiment, the conveyor belt includes the first conveyor belt 11 and the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com