Low-cost ramming material for RH and preparation method thereof

A low-cost, ramming material technology, used in the field of smelting refractory materials, can solve the problems of waste disposal environmental pollution, narrow application scope, environmental pollution, etc., and achieve the effects of low cost, cost reduction, and satisfaction of use requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

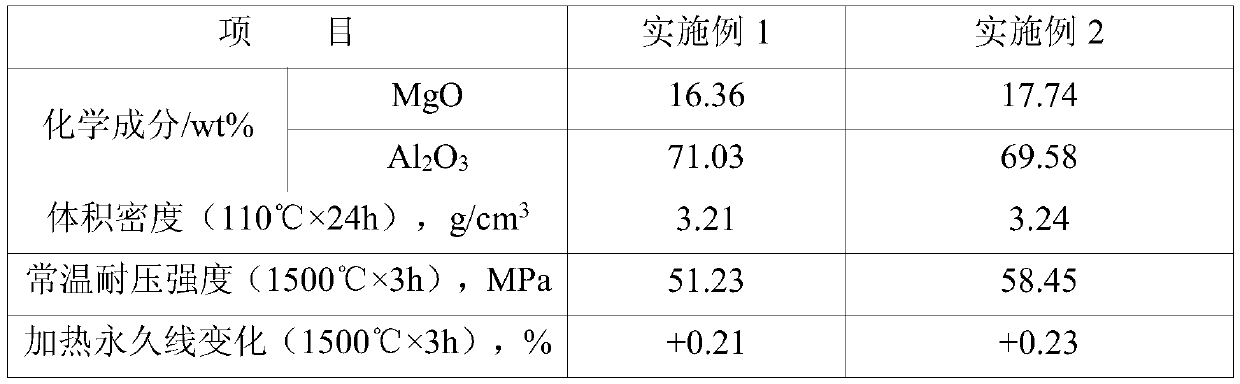

Embodiment 1

[0022] After the used waste refractory materials are recycled, sorted and sorted, the residual iron, residual steel and metamorphic layer on the surface are removed; the used waste refractory materials (Al 2 o 3 content is 91.69wt%, MgO content is 7.66wt%) and is ground into three different particle sizes of 3

[0023] According to the mass percentage content, 3<particle size≤5mm used waste refractory material 20%, 1<particle size≤3mm used waste refractory material 25%, particle size≤1mm used waste refractory material 30%, particle size≤0.088 mm magnesia 22%, high alumina cement 2.8%, sodium tripolyphosphate admixture 0.2%;

[0024] Add it into a blender, stir and mix until uniform, and get ramming material for RH.

Embodiment 2

[0026] After the used waste refractory materials are recycled, sorted and sorted, the residual iron, residual steel and metamorphic layer on the surface are removed; the used waste refractory materials (Al 2 o 3 The content is 89.32wt%, the MgO content is 8.02wt%), please supplement the component content data) and be crushed into three different particle sizes: 3

[0027] According to the mass percentage content, 25% of used waste refractory materials for 3<particle size≤5mm, 22% of used waste refractory materials for 1<particle size≤3mm, 25% of used waste refractory materials for particle size≤1mm, particle size≤0.088 mm magnesia 24%, high alumina cement 3.8%, sodium tripolyphosphate admixture 0.2%;

[0028] Add it into a blender, stir and mix until uniform, and get ramming material for RH.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com