Smooth wear-resistant coating and preparation method thereof

A wear-resistant paint and slippery technology, applied in the field of slip-resistant wear-resistant paint and its preparation, can solve the problems of lack of slippery and wear resistance, and achieve the effects of improving aesthetics, high lubricity and reducing wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

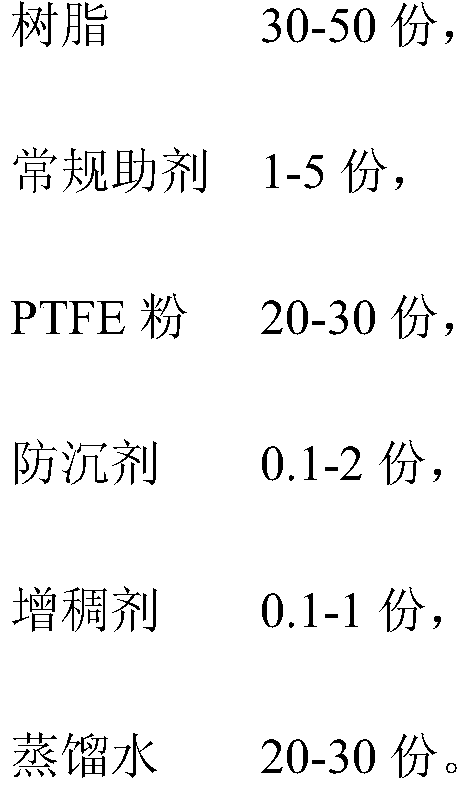

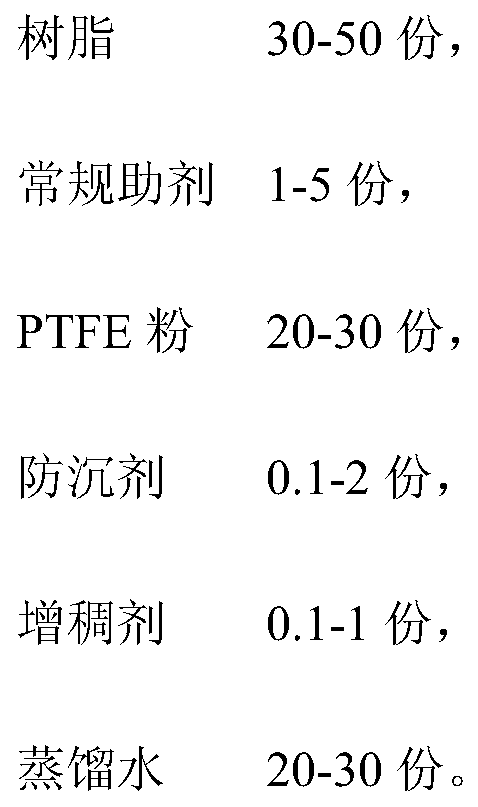

[0033] A smooth wear-resistant coating, raw materials include: water-based polyester resin with a pH value of 7.0-9.0, water-based silicone defoamer TEGO Airex902W, amine neutralizer dimethylethanolamine, purity>99.9%, molecular weight less than 1 Ten thousand, PTFE powder with a particle size of 0.5-15 μm, fumed silica, thickener polyurethane associative rheological additive Hemings R-299 and distilled water, the parts by weight of each raw material are shown in the following table 1;

[0034] The preparation method of this coating comprises the following steps:

[0035] (1) Add water-based silicone defoamer, PTFE powder, fumed silica and 10 parts of distilled water into the container and stir for 20 minutes;

[0036] (2) Add an equal amount of zirconium beads to grind for 80 minutes, and filter to obtain the color paste;

[0037] (3) Add resin, amine neutralizer and 10 parts of distilled water into the container and stir for 20 minutes;

[0038] (4) Add the color paste obt...

Embodiment 2

[0040] A smooth and wear-resistant coating, raw materials include: water-based polyester resin with a pH value of 7.0-9.0, water-based silicone defoamer TEGO Airex902W, amine neutralizer dimethylethanolamine, substrate wetting agent BYK-190 PTFE powder with a purity >99.9%, a molecular weight of less than 10,000, and a particle size of 0.5-15 μm, fumed silica, organic bentonite, thickener polyurethane associative rheology additive Hemings R-299 and distilled water, each The parts by weight of raw materials are shown in the following table 1;

[0041] The preparation method of this coating comprises the following steps:

[0042] (1) Add water-based silicone defoamer, substrate wetting agent, PTFE powder, fumed silica, organic bentonite and 10 parts of distilled water into the container and stir for 20 minutes;

[0043] (2) Add an equal amount of zirconium beads to grind for 80 minutes, and filter to obtain the color paste;

[0044] (3) Add resin, amine neutralizer and 10 part...

Embodiment 3

[0047] A smooth and wear-resistant coating, raw materials include: water-based polyester resin with a pH value of 7.0-9.0, water-based silicone defoamer TEGO Foamex810, amine neutralizer dimethylethanolamine, substrate wetting agent BYK-2012 PTFE powder with a purity of >99.9%, a molecular weight of less than 10,000, and a particle size of 0.5-15 μm, organic bentonite, thickener polyurethane associative rheological additive Hemings R-299 and distilled water, the weight parts of each raw material See Table 1 below;

[0048] The preparation method of this coating comprises the following steps:

[0049] (1) Add silicone defoamer, substrate wetting agent, PTFE powder, organic bentonite and 10 parts of distilled water into the container and stir for 20 minutes;

[0050] (2) Add an equal amount of zirconium beads to grind for 80 minutes, and filter to obtain the color paste;

[0051] (3) Add resin, amine neutralizer and 10 parts of distilled water into the container and stir for 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com