A method for testing the adhesion performance of self-adhesive waterproof membranes in low temperature environments

A waterproof membrane and bonding performance technology, which is applied in the direction of measuring devices, analysis materials, instruments, etc., can solve the problems of lack of judgment basis for the bonding effect of waterproof membranes, and achieve the advantages of easy automatic testing, reduced testing time, and convenient testing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

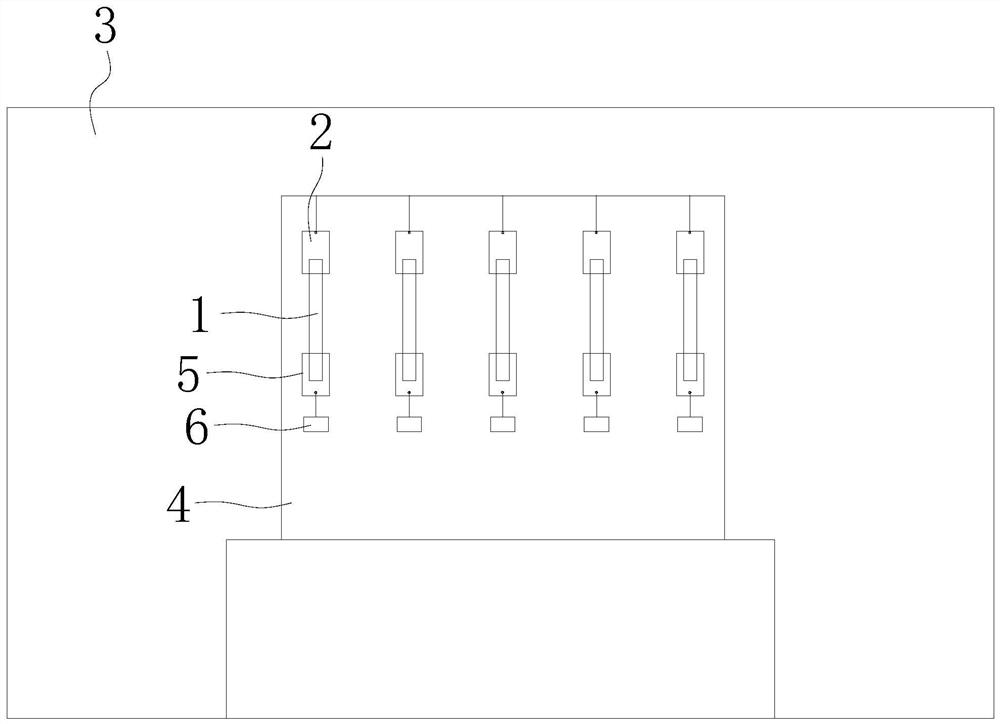

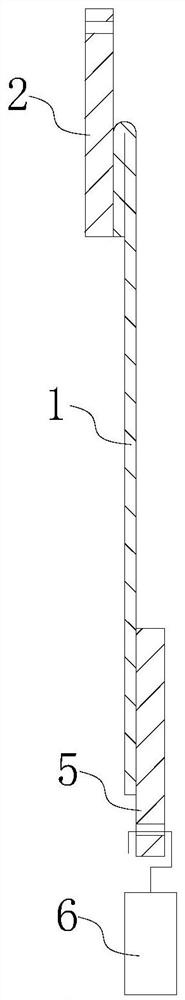

[0051] refer to figure 1 and figure 2 , this embodiment discloses a method for testing the adhesion performance of a self-adhesive waterproof membrane in a low temperature environment, including:

[0052] S1: Cut and make waterproof membrane sample 1, the waterproof membrane is self-adhesive waterproof membrane;

[0053] S2: Bond the waterproof membrane sample 1 with the first test connection block 2 at room temperature (25±2°C) to form a first connection body;

[0054] The self-adhesive waterproof membrane is more securely bonded at room temperature, so that one end of the waterproof membrane sample 1 is firmly connected to the first test connection block 2, and the waterproof membrane sample 1 is kept away from the first test connection block 2 One end of the terminal is used as the test terminal, which is convenient for testing;

[0055] S3: Place the first connecting body and the adhesion testing equipment 4 in the low temperature test chamber 3 for a preset time t 1 ...

Embodiment 2

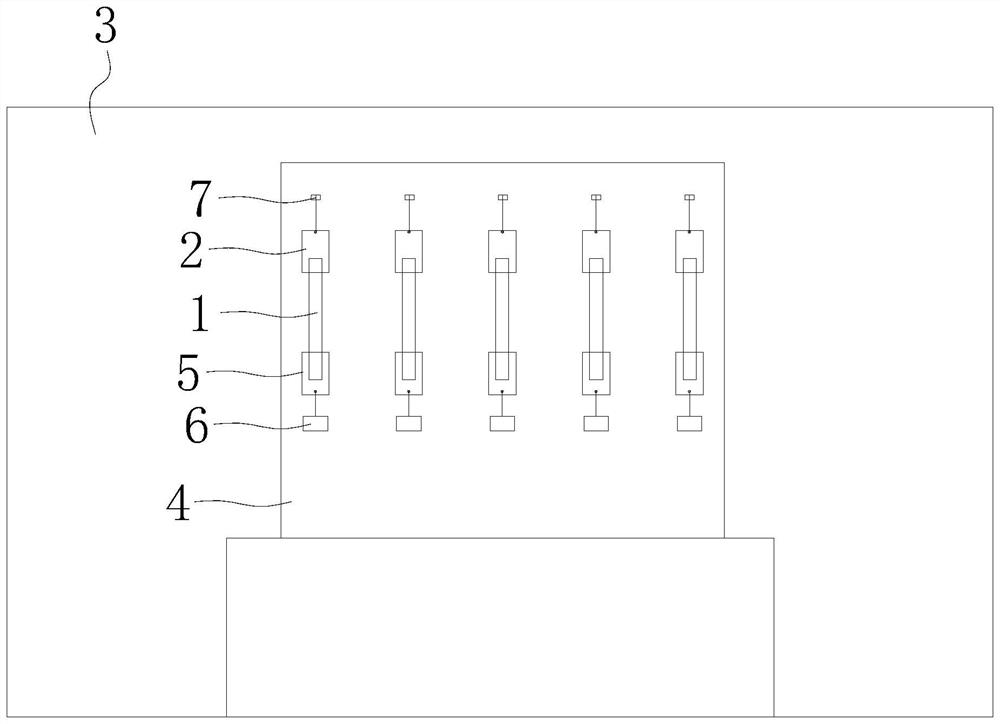

[0066] refer to image 3 as well as Figure 4 , based on Example 1, this example discloses another method for testing the adhesion performance of self-adhesive waterproof rolls in a low-temperature environment. The difference between this example and the above-mentioned Example 1 is that:

[0067] This test method also uses an automatic timing device (not shown in the figure), which includes an electronic timer body (not shown in the figure), a timing start trigger switch 7, and a timing stop sensor 8, holding the adhesiveness measuring instrument Including the base 401, the base 401 is provided with a suspension hook 9, the suspension hook 9 includes a fixed end 901 and a suspension end 902, the fixed end 901 is fixed to the base 401, and the suspension end 902 is used to hang the second connecting body to be tested, The timing start trigger switch 7 is arranged under the fixed end 901 and is in contact with the lower surface of the fixed end 901. Before the second connectin...

Embodiment 3

[0071] refer to Figure 5 , based on Example 1, this example discloses another method for testing the bonding performance of self-adhesive waterproof rolls in a low-temperature environment. The differences between this example and Example 1 are:

[0072] At least one test mark line 501 is set on the second test connection block, and the test mark line 501 is located in the bonding range between the waterproof membrane sample and the second test connection block.

[0073] After the second connecting body is suspended, the lower end face of the second test connection block is the first end face, and the upper end face is the second end face.

[0074] In this embodiment, the distance from the test mark line 501 to the first end surface is H, and the value of H is 0

[0075] The value of H can be 40mm, 35mm, 30mm, 25mm, 20mm, 15mm, 10mm, 5mm.

[0076] In this embodiment, the mode of testing the bonding performance of the waterproof coiled material is:

[0077] After the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com