A kind of nontoxic gold-plated gold salt and its synthetic method

A synthesis method and technology of gold salt, applied in the field of electroplating gold, can solve the problems of poor wear resistance of the coating, toxicity of malononitrile, and high cost of the plating solution, and achieve the effects of stable performance, strong adhesion and corrosion protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

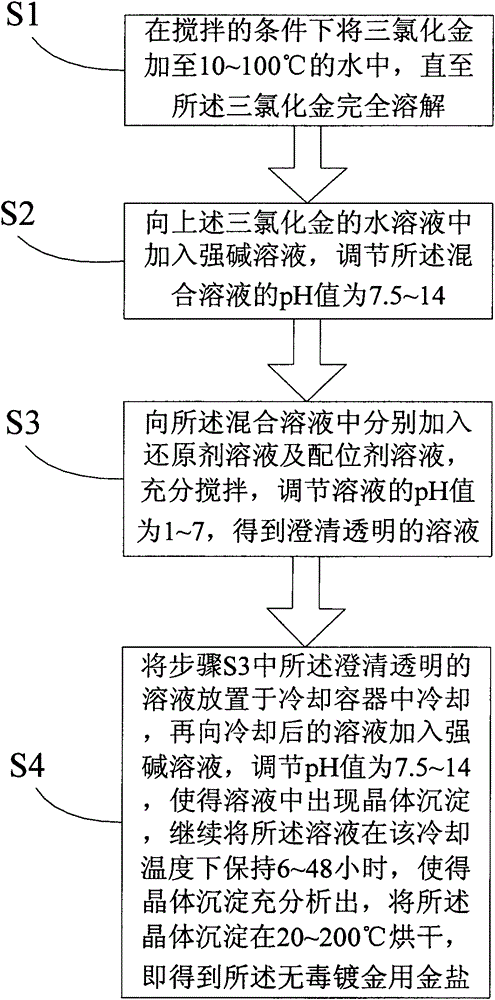

[0035] see figure 1 , figure 1 It is a schematic flow chart of the method for synthesizing a gold salt for non-toxic gold plating of the present invention. The synthetic method of gold salt for nontoxic gold plating of the present invention comprises the following steps:

[0036] Step S1: adding gold trichloride to water at 10-100° C. under stirring until the gold trichloride is completely dissolved;

[0037] Step S2: adding a strong alkali solution to the aqueous solution of gold trichloride to adjust the pH value of the mixed solution to 7.5-14; in this step S2, the reaction equation is: That is, AuO - 2 mixed solution.

[0038] Step S3: Add a reducing agent solution with a concentration of 0.1mol / L to 10mol / L and a complexing agent solution with a concentration of 1.0mol / L to 10mol / L respectively into the mixed solution, stir well, and adjust the pH value of the solution From 1 to 7, a clear and transparent solution was obtained.

[0039] In this step, the reducing ...

Embodiment 1

[0067] Add 1.0L deionized water into the reaction vessel, turn on the stirring and heating device, raise the temperature to 10°C, add 20g of gold trichloride after the temperature stabilizes, and keep stirring until the gold trichloride is completely dissolved; 16.8g KOH, dissolve it in 3L of water at 10°C to prepare a KOH solution, slowly add it dropwise to the above-mentioned gold trichloride solution, measure the pH value while adding, and adjust the pH value to 7.5; In water heated to 10°C, add 97.32g of potassium citrate and 339g of NCCH with stirring 2 COOCH 2 CH 3 , to be completely dissolved to obtain a concentration of 0.1mol / L potassium citrate solution and a concentration of 1.0mol / L NCCH 2 COOCH 2 CH 3 solution; the above potassium citrate solution and NCCH 2 COOCH 2 CH 3 The solution was slowly added dropwise to the above solution, and the pH value was adjusted to 1 to obtain a clear and transparent solution; the above obtained container containing the clea...

Embodiment 2

[0069] Add 1.5L deionized water into the reaction vessel, turn on the stirring and heating device, raise the temperature to 40°C, add 35g of gold trichloride after the temperature stabilizes, and keep stirring until the gold trichloride is completely dissolved; Dissolve 336g KOH in 3L water at 40°C to prepare KOH solution, slowly add it dropwise to the above-mentioned gold trichloride solution, measure the pH value while adding, and adjust the pH value to 9; heat in 3L To water at 40°C, add 52.84g ascorbic acid and 1395g NC (CH 2 ) 2 COO(CH 2 ) 3 CH 3 , to be completely dissolved to obtain a concentration of 0.1mol / L ascorbic acid solution and a concentration of 3.0mol / L NC (CH 2 ) 2 COO(CH 2 ) 3 CH 3 solution, the above ascorbic acid solution and NC (CH 2 ) 2 COO(CH 2 ) 3 CH 3 The solution was slowly added dropwise to the above solution, and the pH value was adjusted to 3 to obtain a clear and transparent solution; the above obtained container containing the clea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com