Luminescent ceramic with high afterglow intensity and preparation method thereof

A technology of luminescent ceramics and strength, applied in the field of ceramics, can solve the problems of poor luminescent afterglow performance, large loss of luminous intensity, and decreased luminous intensity of luminescent ceramic tiles, so as to avoid rain erosion and acid-base corrosion, improve afterglow intensity, reduce The effect of hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

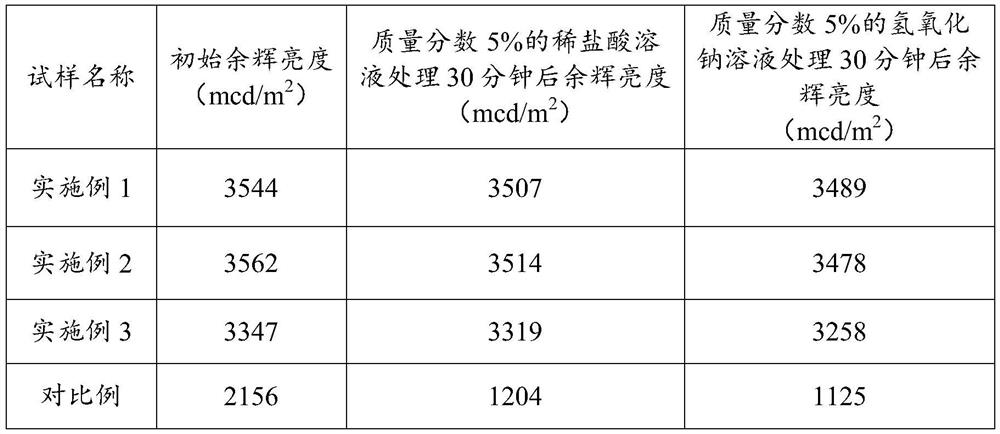

Examples

Embodiment 1

[0027] A luminescent ceramic with high afterglow intensity, the bottom-up structure of the luminescent ceramic is: a body layer, a surface glaze layer, a bonding layer, a luminescent layer, a transparent layer and a pattern layer, wherein the bonding layer and the transparent layer are The materials are all low-temperature glazes, and the material of the light-emitting layer is a mixture of low-temperature glaze and light-emitting materials in a ratio of 50:50. The components and mass percentages of the low-temperature glaze are: SiO 2 40%, Al 2 O 3 10%, Fe 2 O 3 0.01%, TiO 2 0.01%, CaO 8%, K 2 O is 2%, Na 2 O is 2%, B 2 O 3 30%, BaO 4.98% and Li 2 O is 3%; the mass percentage of each component of the material of the surface glaze layer is: SiO 2 60%, Al 2 O 3 25%, Fe 2 O 3 0.2%, TiO 2 0.3%, CaO2.5%, MgO3.0%, K 2 O 2.5%, Na 2 O 3.0%, ZnO 0.5% and ZrO 2 3.0%; the luminescent material is SrAl co-doped with rare earth Eu and Dy 2 O 4 and Ca 2 MgSi 2 O 7 ...

Embodiment 2

[0035] A luminescent ceramic with high afterglow intensity, the bottom-up structure of the luminescent ceramic is: a body layer, a surface glaze layer, a bonding layer, a luminescent layer, a transparent layer and a pattern layer, wherein the bonding layer and the transparent layer are The materials are all low-temperature glazes, and the material of the light-emitting layer is a mixture of low-temperature glaze and light-emitting material in a ratio of 80:20. The components and mass percentages of low-temperature glaze are: SiO 2 41.25%, Al 2 O 3 13.59%, Fe 2 O 3 0.01%, TiO 2 0.02%, CaO 7.6%, K 2 O is 1.7%, Na 2 O is 2%, B 2 O 3 25%, BaO 6.46% and Li 2 O is 2.37%; the mass percentage of each component of the material of the surface glaze layer is: SiO 2 65%, Al 2 O 3 20%, Fe 2 O 3 0.1%, TiO 2 0.1%, CaO 1.5%, MgO 3%, K 2 O 4.5%, Na 2 O2.2%, ZnO 0.1% and ZrO 2 3.5%; the luminescent material is SrAl co-doped with rare earth Eu and Dy 2 O 4 luminescent mate...

Embodiment 3

[0043] A luminescent ceramic with high afterglow intensity, the bottom-up structure of the luminescent ceramic is: a body layer, a surface glaze layer, a bonding layer, a luminescent layer, a transparent layer and a pattern layer, wherein the bonding layer and the transparent layer are The materials are all low-temperature glazes, and the material of the light-emitting layer is a mixture of low-temperature glaze and light-emitting material in a ratio of 70:20. The components and mass percentages of low-temperature glaze are: SiO 2 47.17%, Al 2 O 3 10.12%, Fe 2 O 3 0.02%, TiO 2 0.01%, CaO 5.54%, K 2 O is 1.27%, Na 2 O is 1.48%, B 2 O 3 27.05%, BaO 4.78% and Li 2 O is 2.56%; the mass percentage of each component of the material of the surface glaze layer is: SiO 2 63.3%, Al 2 O 3 21%, Fe 2 O 3 0.2%, TiO 2 0.2%, CaO2.5%, MgO2.0%, K 2 O3.5%, Na 2 O3.8%, ZnO0.5% and ZrO 2 3%; the luminescent material is SrAl co-doped with rare earth Eu and Dy 2 O 4 , Sr 2 Mg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com