Substrate for high-brightness LED light source and preparation method thereof

A LED light source and high-brightness technology, which is applied in the direction of chemical instruments and methods, applications, ceramic products, etc., can solve the problems of poor heat dissipation of LED substrates, low thermal conductivity, and unsuitable high-brightness LEDs, etc., to achieve heat dissipation and impurities Low content, long-lasting effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0076] The invention provides a method for preparing a substrate for a high-brightness LED light source. Silicon carbide and the aforementioned modified silicon carbide whiskers are used to prepare a silicon carbide ceramic plate, the surface of the ceramic is coated with an epoxy resin layer containing gossypol-grafted graphene, and finally Then add an aluminum nitride heat dissipation plate on the surface of the epoxy resin layer.

[0077] The preparation method of a substrate for a high-brightness LED light source specifically includes:

[0078] 1) Silicon carbide and aluminum dihydrogen phosphate are ball-milled with water as a medium, and then ball-milled at low speed after adding modified silicon carbide whiskers. After vacuum degassing, they are injected into a mold to obtain a ceramic green body. After drying and demoulding, vacuum low-temperature sintering is performed to obtain a silicon carbide ceramic plate. ;

[0079] 2) Gossypol-grafted graphene is dispersed in ...

Embodiment 1

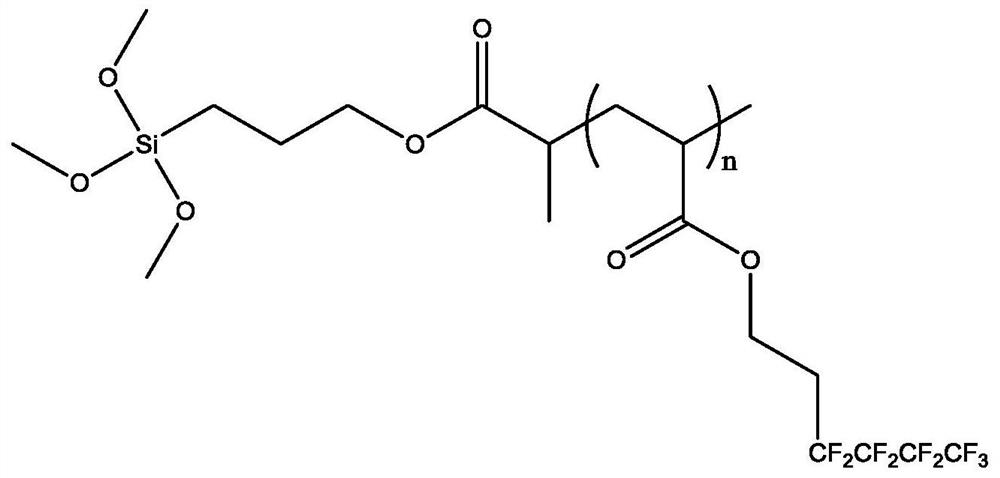

[0098] Example 1: A fluorosilane coupling agent oligomer:

[0099] This embodiment provides a fluorosilane coupling agent oligomer, which is prepared through the following steps: mixing equal weight of xylene and propylene glycol methyl ether as a solvent, filling with nitrogen protection, stirring at 150r / min, mixing 0.04mol KH570, 0.18mol fluorine-containing monomer CH 2 =CH-C(O)-O-CH 2 CH 2 -C 4 F 9 , The mixture of 1.31g azobisisobutyronitrile and 1.18g di-n-butyltin dilaurate was added dropwise into the mixed solvent at 110°C at a constant speed within 2h, and the mixture was kept at 120r / min and stirred for 30min, cooled to room temperature and rotated at low temperature. Evaporate to remove the solvent, and vacuum dry at 45°C to constant weight.

[0100] The molecular weight of the oligomer was determined by gel chromatography and analyzed by size exclusion chromatography, and the weight-average molecular weight of the oligomer was measured to be about 1450, and it...

Embodiment 2

[0102] Embodiment 2: a kind of fluorosilane coupling agent oligomer modified silicon carbide whisker:

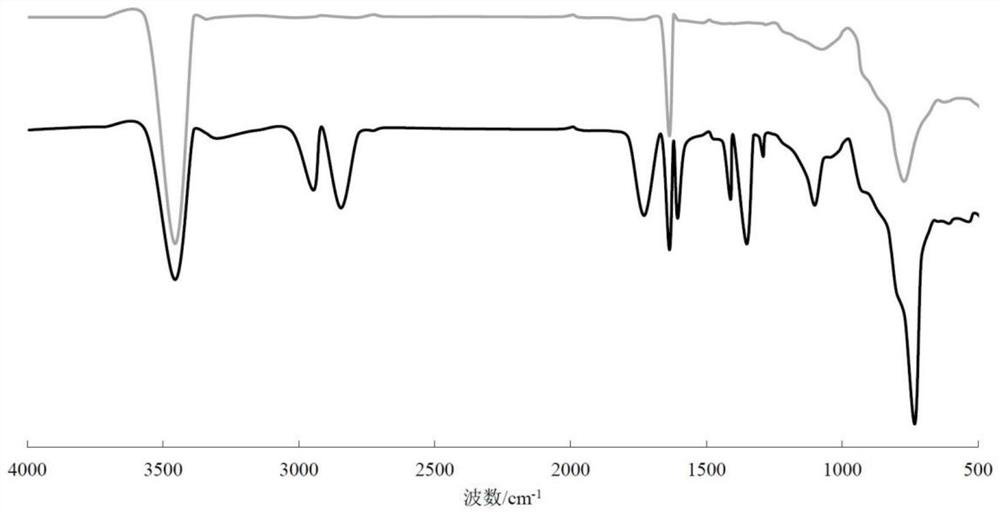

[0103] This embodiment provides a fluorosilane coupling agent oligomer-modified silicon carbide whisker, which is specifically based on the fluorosilane coupling agent oligomer obtained in Example 1 to an average diameter of 300-350 nm and an aspect ratio of 30-40. The silicon carbide whiskers were modified and obtained, and the steps were as follows: 100g silicon carbide whiskers were dispersed in 12L toluene, and the ultrasonic frequency was 60KHz and the ultrasonic intensity was 0.8W / cm. 2 Disperse under conditions for 3h; add 0.8g of fluorosilane coupling agent oligomer and 0.48g of deionized water in turn, slowly heat up to 70°C at 2°C / min, stir at 180r / min for 5h, suction filtration, and alcohol washing for 3 times. Dry to constant weight at 50°C. The FTIR image of silicon carbide whiskers modified by fluorosilane coupling agent oligomer is shown in image 3 shown, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com