Measurement of operating parameters on actuators

A technology of operating parameters and actuators, which is applied in the testing of machine/structural components, fluid pressure actuation system testing, heat measurement, etc., to achieve the effect of optimizing the production system, reducing costs, and facilitating replacement or maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

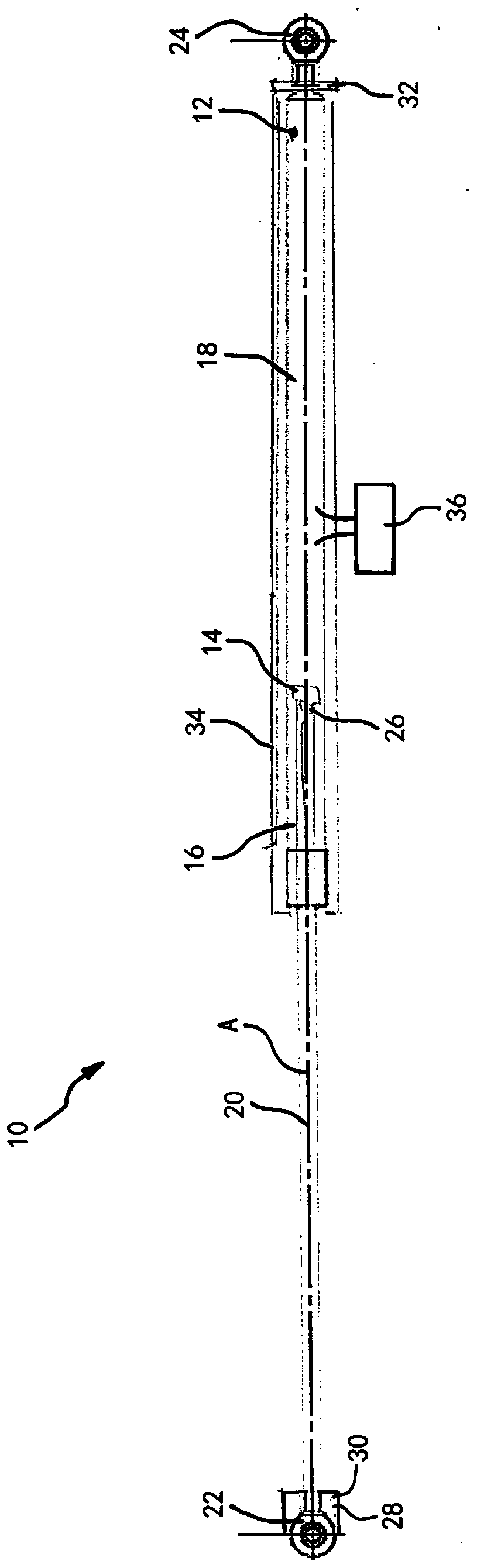

[0029] exist figure 1 In , the actuator according to the invention is denoted generally by 10 . exist figure 1 In the exemplary embodiment shown, the actuator 10 is designed as a hydraulic piston-cylinder assembly 10 .

[0030] The actuator 10 comprises a cylinder 12 in which a piston 14 is arranged displaceably along an axis A. As shown in FIG. The piston 14 divides the interior of the cylinder 12 into a first working space 16 and a second working space 18 . A piston rod 20 is connected to the piston 14 and extends through the first working space 16 and is displaceable along the axis A together with the piston 14 .

[0031] At the end of the piston rod 20 opposite to the piston 14, a first connection unit 22 is arranged, which is adapted to be connected with a superordinate assembly, such as a solar panel. At the opposite end of the actuator 10 to the first connection unit 22 there is arranged a second connection unit 24 adapted to connect with another superordinate compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com