Vertical pressure steam sterilizer with quick cooling, drying and automatic moisturizing functions

A technology of automatic water replenishment and pressure steam, applied in the direction of dry gas arrangement, drying, instruments, etc., can solve the problems of low efficiency, a large amount of time, and the wet state of the sterilized object, and achieve the effect of avoiding the wet state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical solutions and advantages of the present invention more clear, the technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the drawings in the embodiments of the present invention:

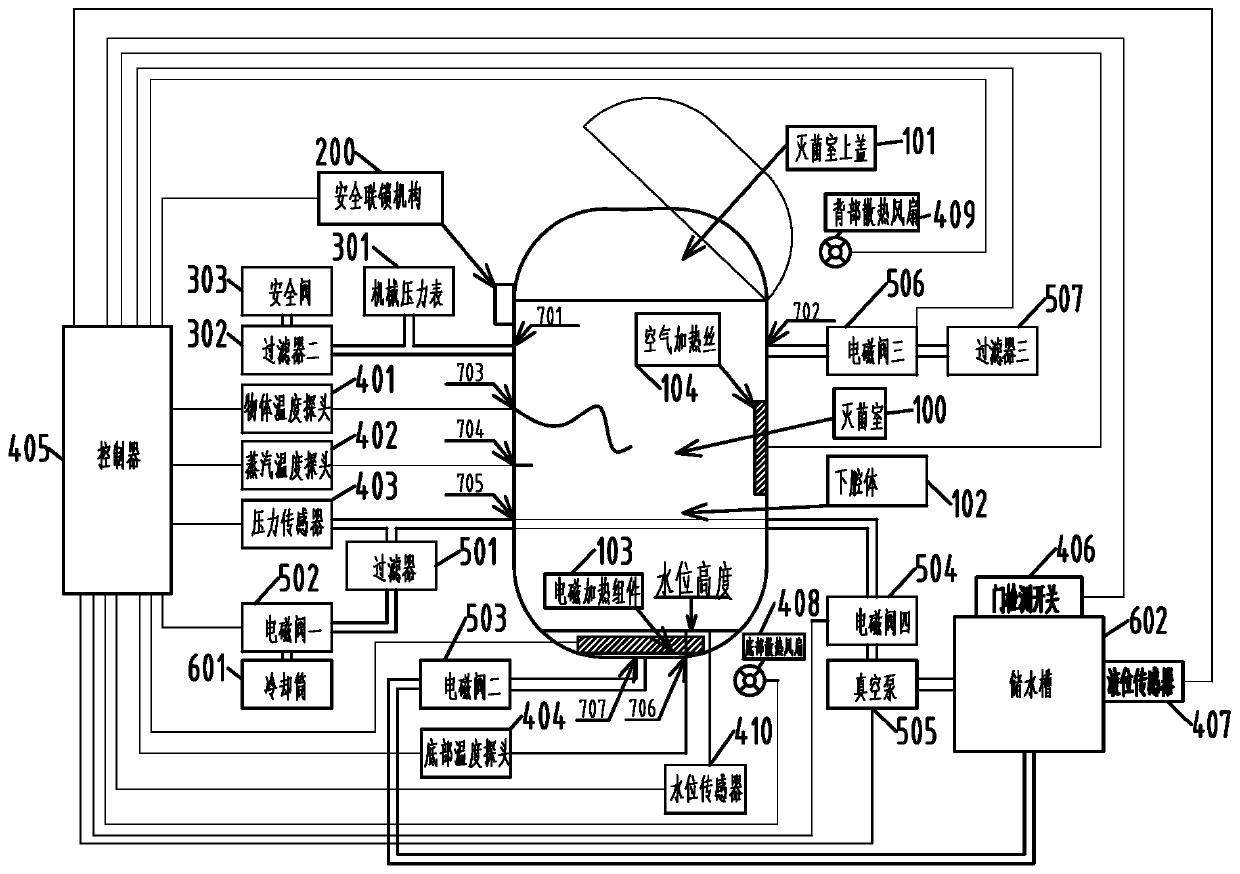

[0021] Such as figure 1 The shown vertical pressure steam sterilizer with rapid cooling and drying and automatic water supply function includes a sterilization chamber 100, which has a sterilization chamber upper cover 101, and its bottom has a lower cavity 102, the lower cavity 102 has an electromagnetic heating assembly 103 and an air heating wire 104 inside. The upper cover 101 of the sterilization chamber can be opened and closed, the electromagnetic heating assembly 103 is installed at the bottom of the lower cavity 102 , and the air heating wire 104 is installed at the middle of the lower cavity 102 . The electromagnetic heating assembly 103 is used to heat the water at the bottom of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com