A simple slide rail surface degreasing and cleaning device

A technology for cleaning devices and slide rails, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as low work efficiency, low applicability, and inapplicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

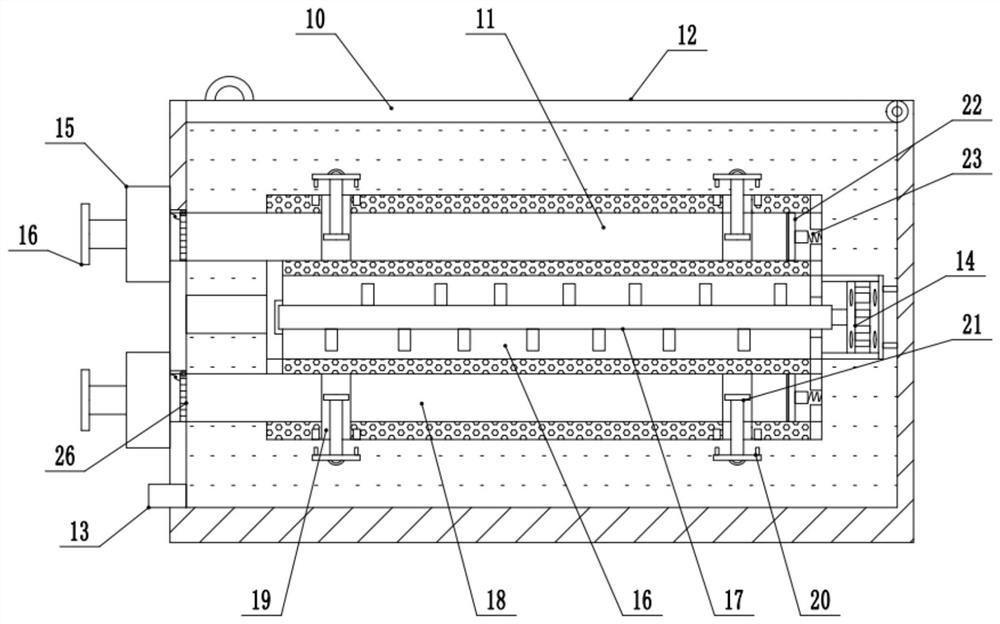

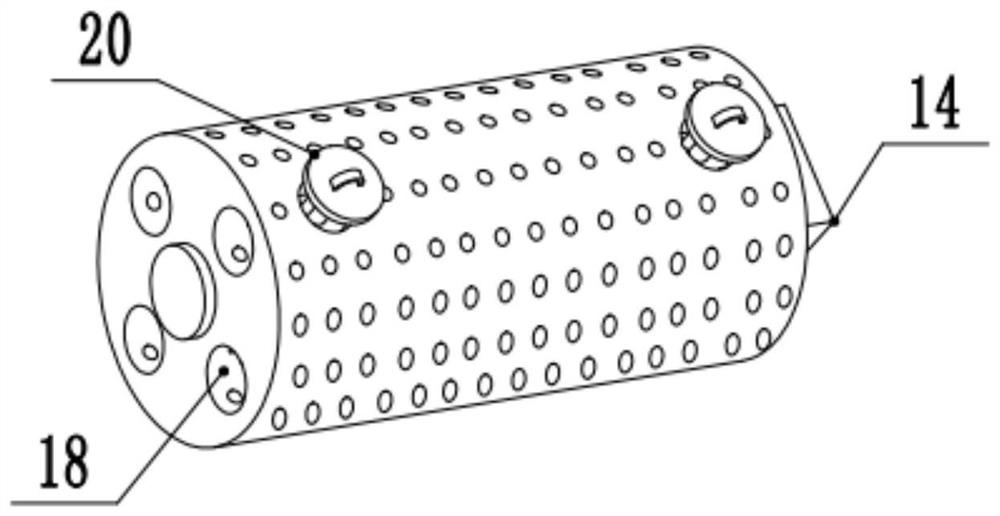

[0022] see Figure 1-3 , a simple surface degreasing and cleaning device for slide rails, comprising a box body 10 and an inner pipe 11; The inside of the box body 10 is filled with a large amount of lye, and the lye has a good effect of removing oil stains. The top of the box body 10 is hinged with a group of box covers 12, and the upper left side of the box cover 12 is fixedly equipped with a handle that is convenient for opening and closing the box cover 12, and is used for adding lye inside the box body 10 by opening and closing the box cover 12 And the operation to the inner parts of the box body 10. The inside of the box 10 is provided with a set of inner tubes 11 coaxial with the box 10, the middle part of the left side of the inner tube 11 is fixedly connected to the left side wall of the box 10, and the inside of the box 10 is ring-shaped. There are four sets of slide rail fixing cavities 18, and the left side of the slide rail fixing cavities 18 is provided with an...

Embodiment 2

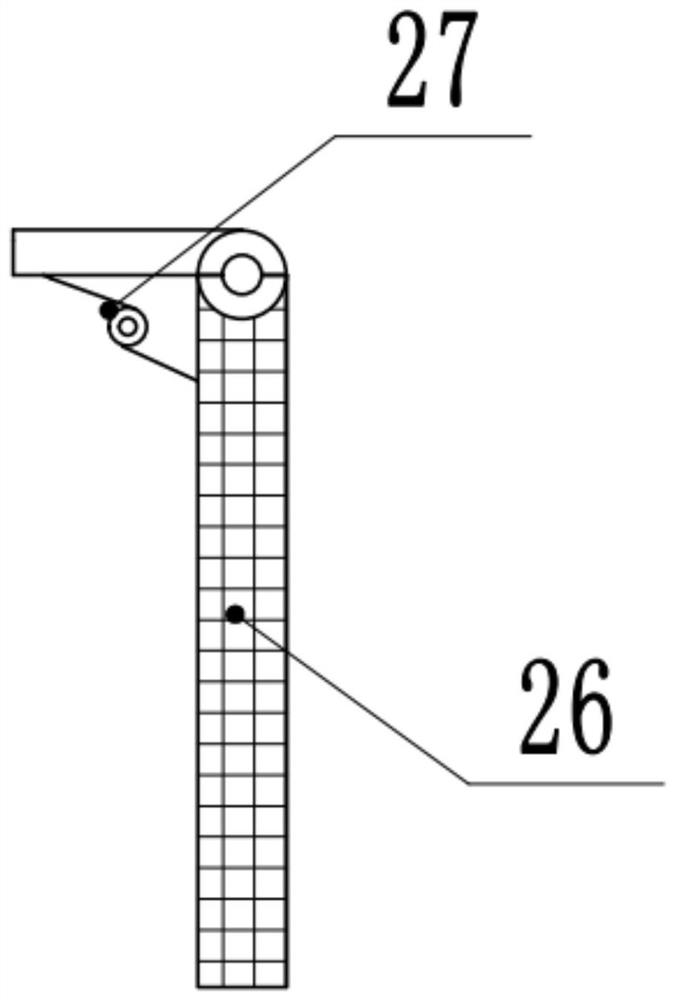

[0027] refer to Figure 4 , on the basis of Embodiment 1, a group of dust removal boxes 15 are arranged between the slide rail inlet 16 and the slide rail hole, and a fan 25 is fixedly installed on the inner upper side of the dust removal box 15, and a fan 25 is fixedly installed on the inner lower side of the slide rail inlet 16. There is a group of dust grooves 24 with an inverted frustum-shaped structure. When the slide rail provides the slide rail inlet 16 to enter the fan 25, the fan 25 is provided to continuously blow the air, and the dust on the slide rail can be removed in advance. Fall into the dust groove 24 under the effect of dust groove 24, and the bottom end of dust groove 24 is connected with the dust outlet that is used to discharge dust.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com