Reinforcement production line for prefabricated bottom plate of large-span laminated slab

A laminated board, large-span technology, applied in the online network, applications, household appliances, etc., can solve the problems of low efficiency, delay in working hours, and inability to tie together, etc., to achieve the effect of convenient welding, easy removal, and good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

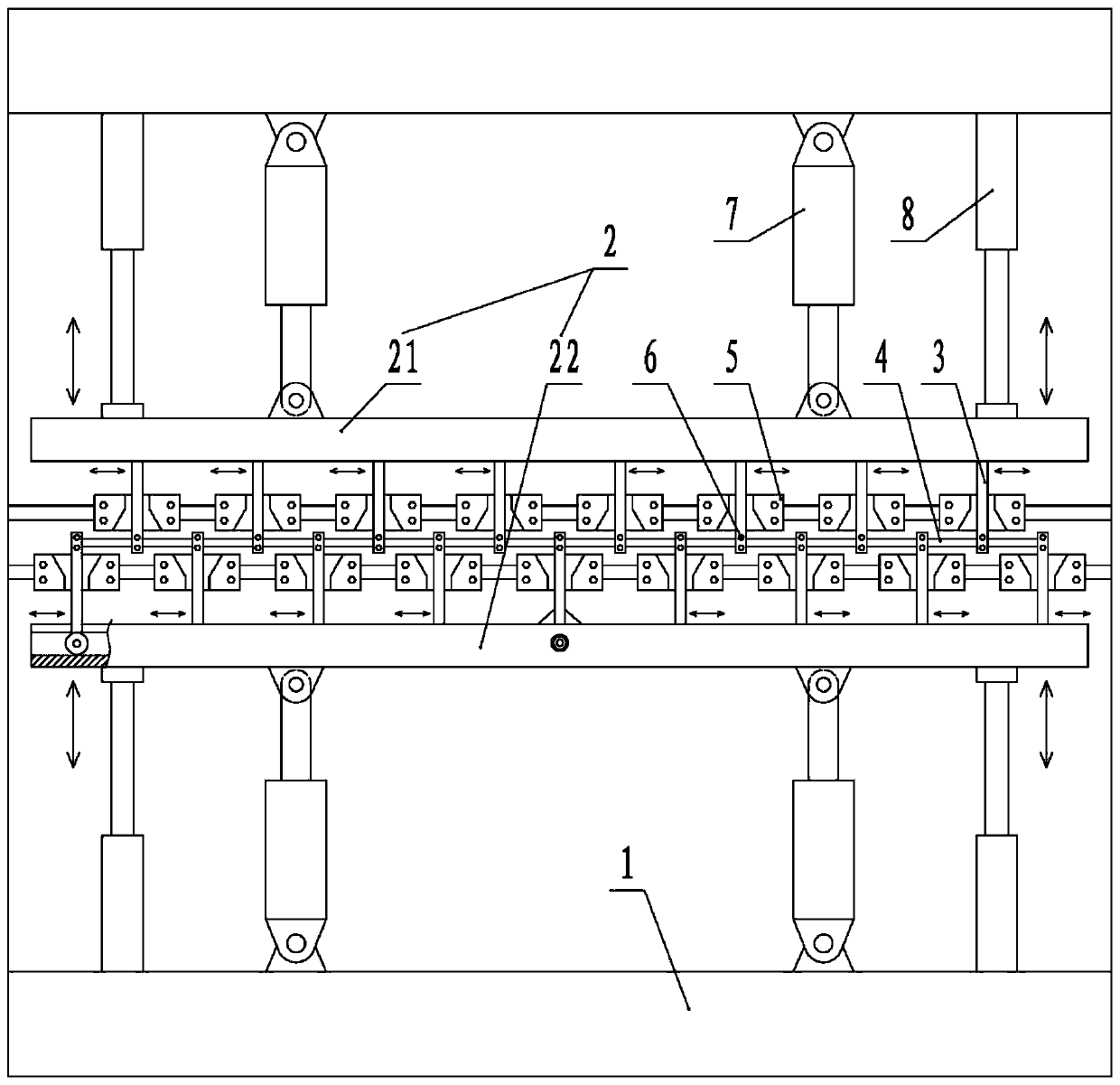

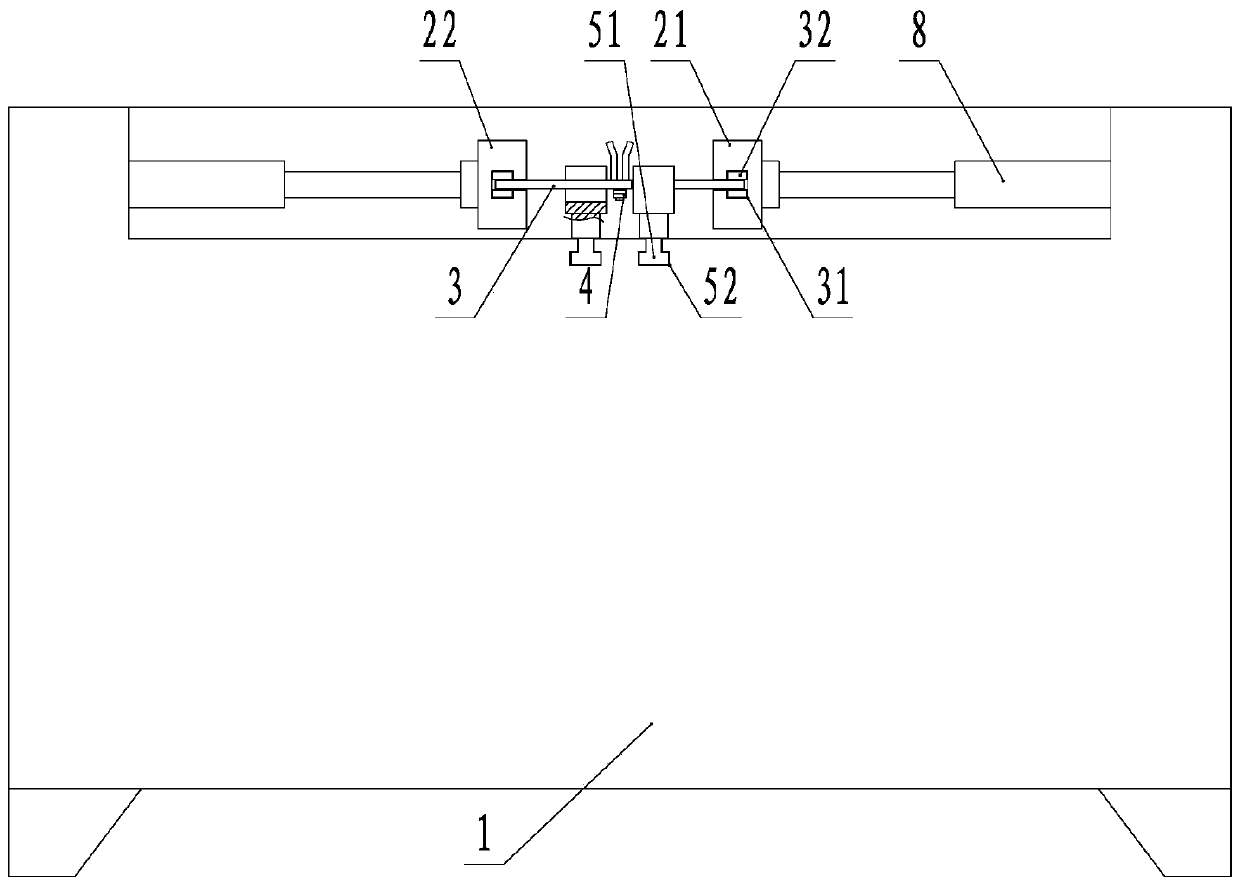

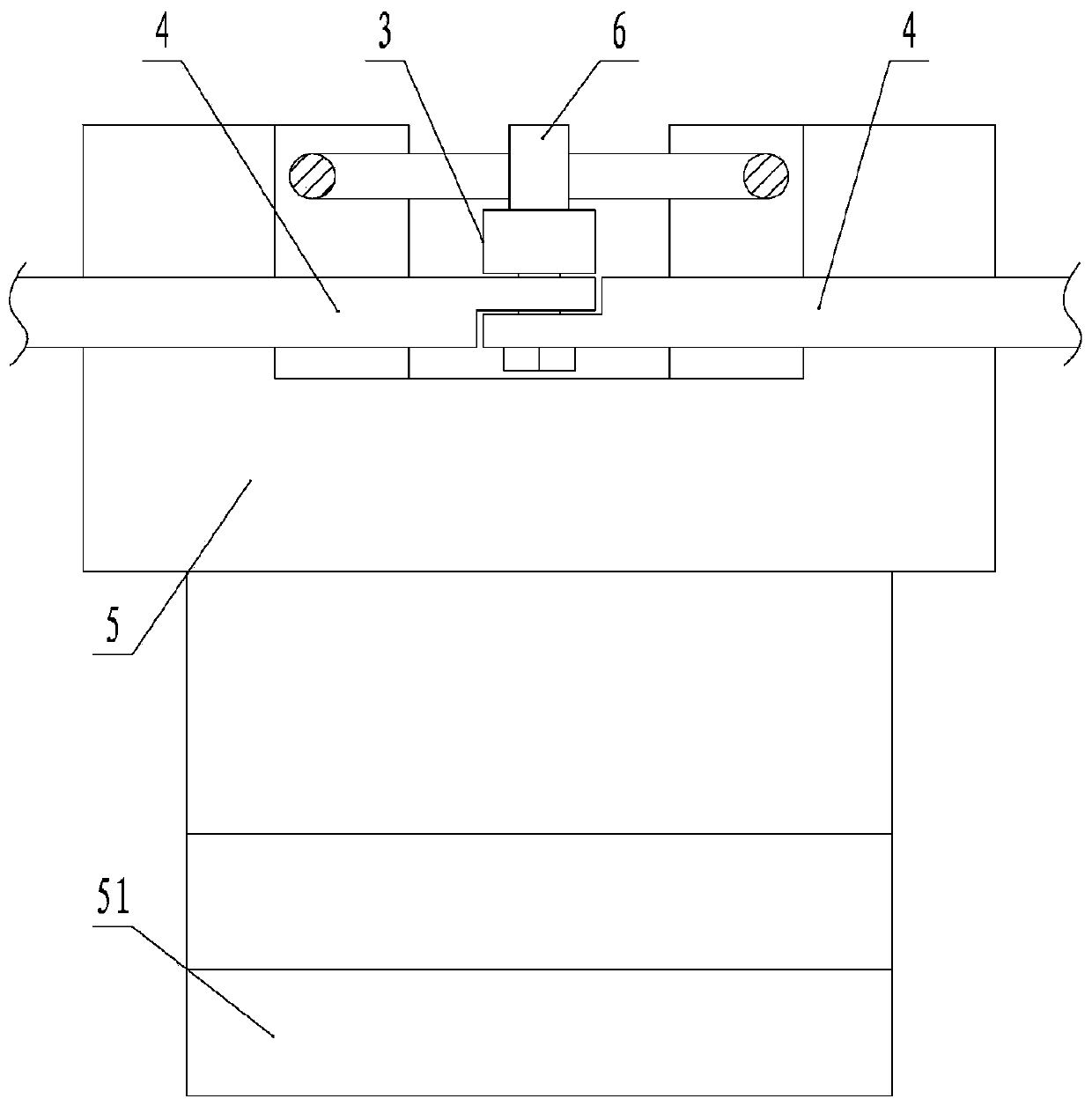

[0033] Such as Figure 1-11 As shown, the specific structure of the present invention is: a prefabricated floor reinforcement production line for large-span laminated slabs, comprising reinforcement equipment, a welding reinforcement device, and a reinforcement platform. The reinforcement equipment includes a body 1, and the body 1 A movable splint 2 is arranged horizontally opposite, and the splint 2 includes a first splint 21 and a second splint 22 parallel to each other. The first splint 21 and the second splint 22 move close to and away from at the same speed at the same time; the first splint 21, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com