Laser pipe cutter with 3D bevel cutting function and control method

A bevel cutting and pipe cutting machine technology, applied in laser welding equipment, household appliances, manufacturing tools, etc., can solve the problems of inability to meet production needs, inability to perform co-edge cutting, increase processing time, etc., to achieve small runout and simplification Equipment, the effect of shortening tails

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

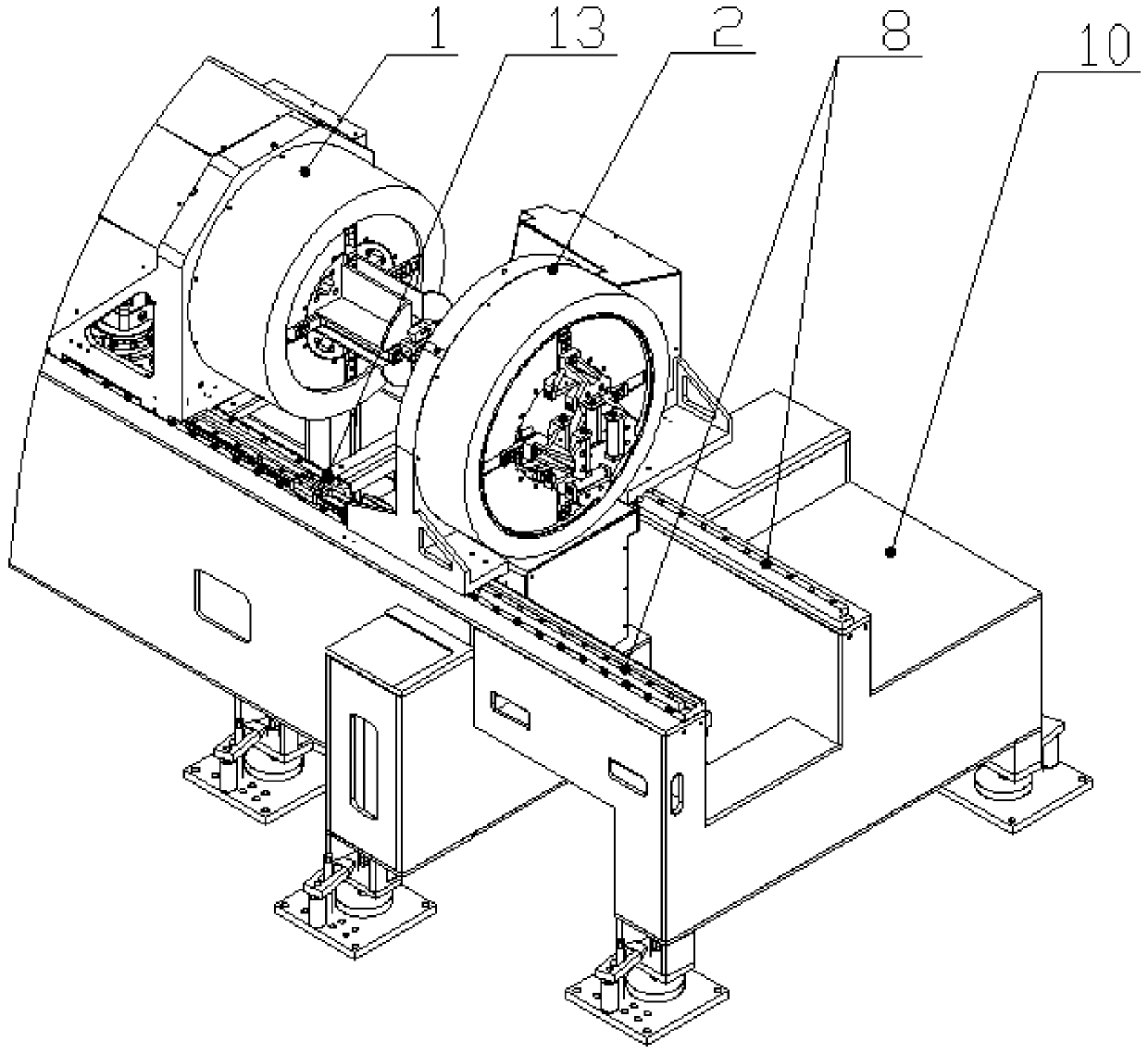

[0026] see figure 1 , the installation form of the front chuck and the headstock of the present invention; including a front chuck 2, a headstock 1, a pair of linear guide rails 8 and a bed 10, so that the front chuck and the headstock are installed on the same pair of linear guide rails superior.

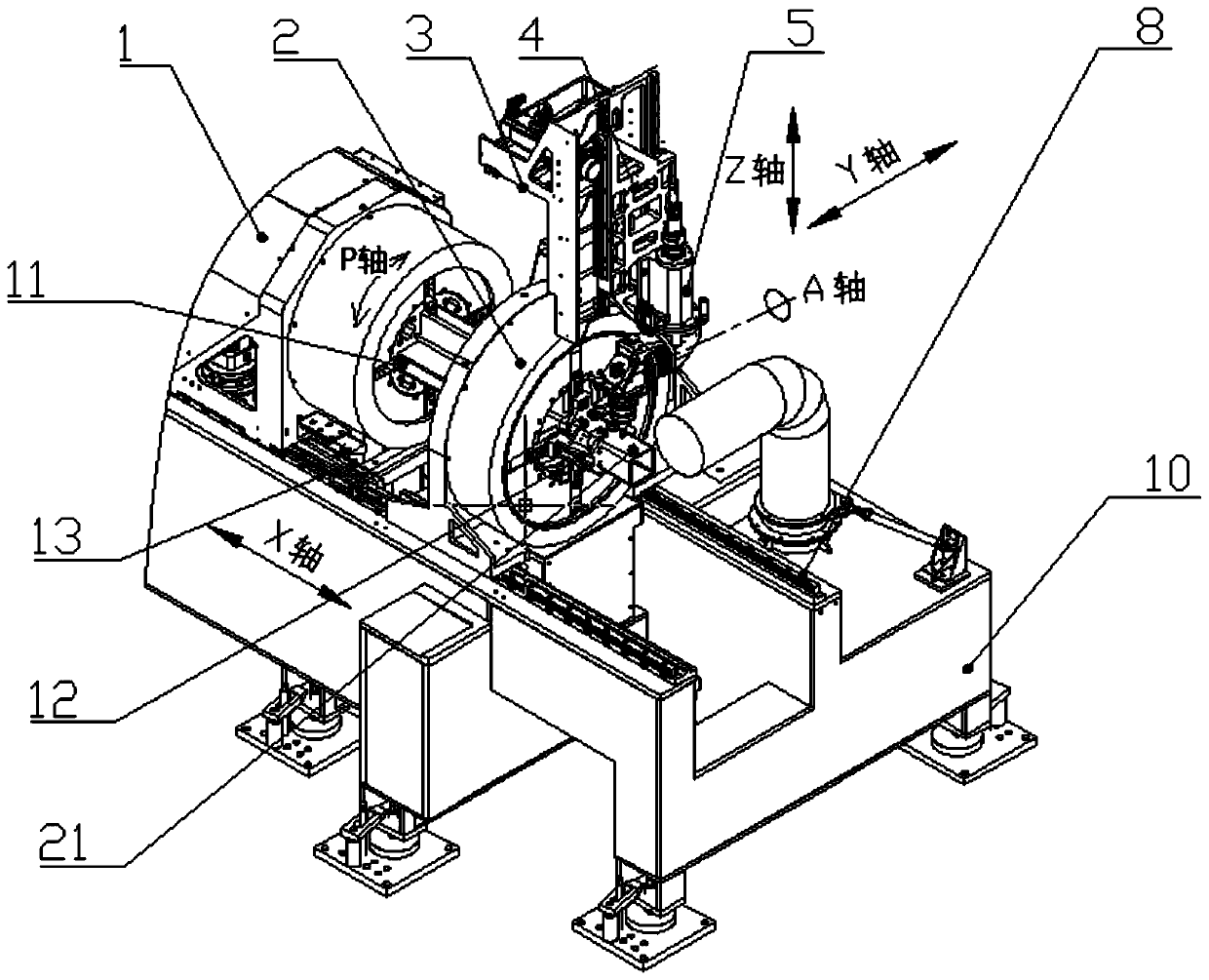

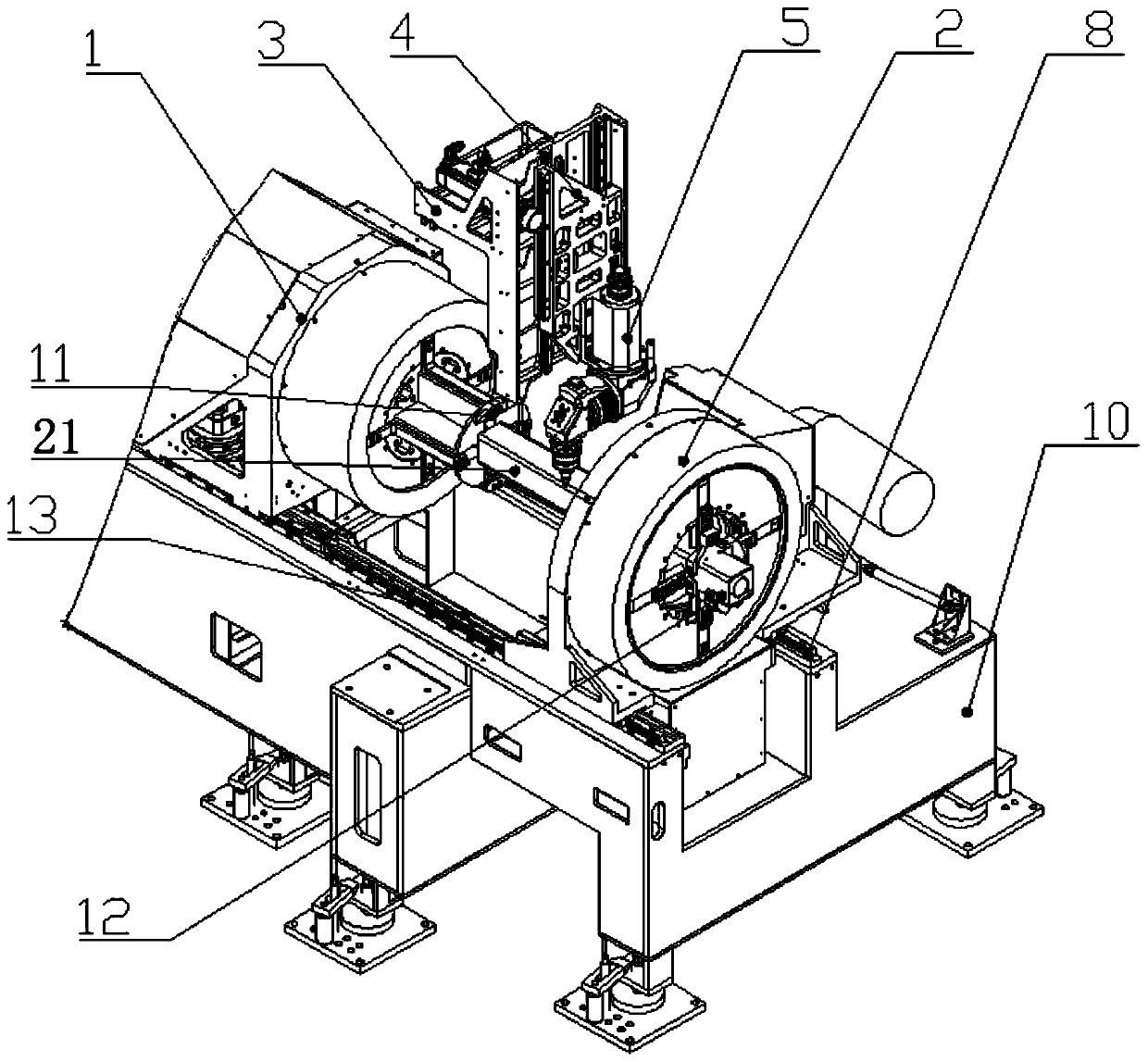

[0027] see figure 2 , the implementation of the pipe 3D groove function in the present invention. It includes a front chuck 2, a headstock 1, a Y-axis mechanism, a Z-axis mechanism and a 3D laser cutting head 5; the headstock 1 and the front chuck 2 are used to clamp the pipe, so that the pipe, the headstock 1 and the front chuck 2 synchronous rotation (P-axis); the headstock clamping claw 11 clamps the pipe and moves along the linear guide rail X-axis direction; The X axis moves; the laser cutting head 5 can move along the horizontal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com