Dry Granular Glaze for Soft Polishing Brick and Its Application

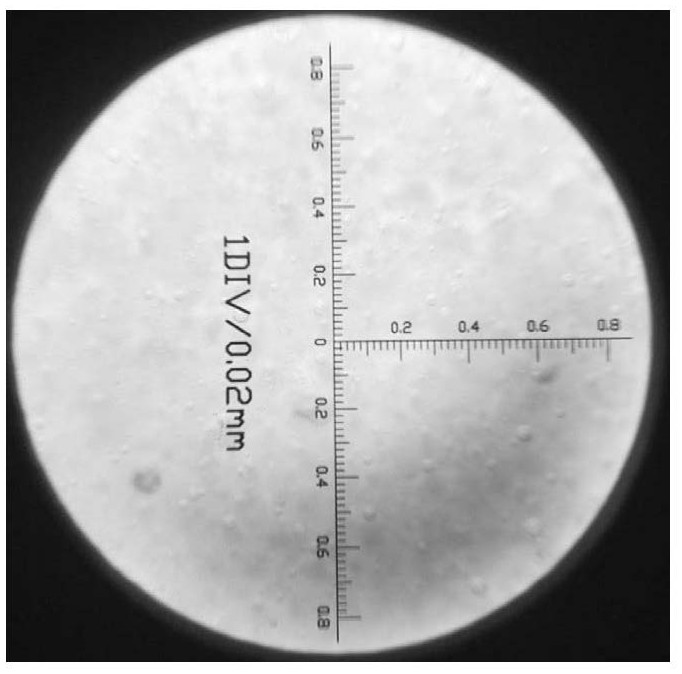

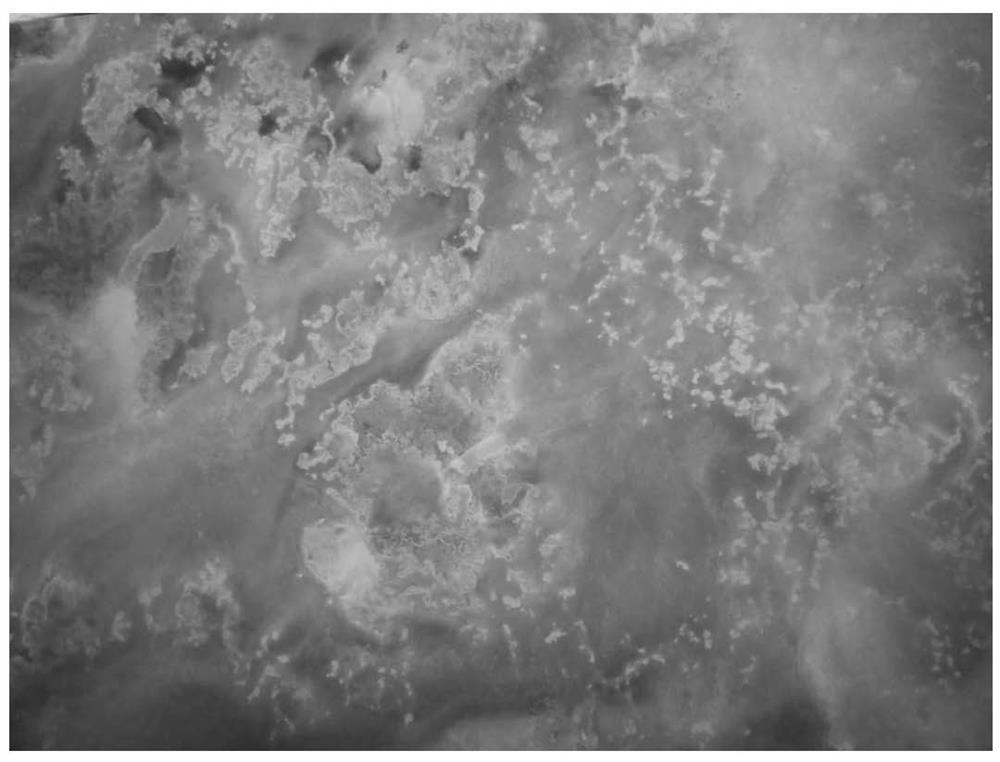

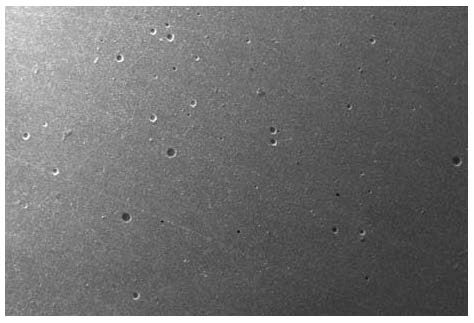

A dry-grain glaze and dry-grain technology, which is applied in the field of ceramic building materials, can solve the problems of less glazing amount of dry-grain glaze, poor glaze water ripple, complicated process, etc., and achieve the effects of less water ripple, fewer pores, and low luminosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] 1. Press common green body powder into green body.

[0046] 2. The green body is dried in a drying kiln, and the moisture content of the dried green body is controlled within 0.5%.

[0047] 3. Inkjet printing pattern on the dried green body.

[0048] 4. Prepare dry grain glaze. The formula of the dry granule glaze is: mixed dry granule 52%; dry granule suspending agent glue: 31%; glaze powder: 4%; water: 13%. The dry particle suspension agent glue includes: debonding agent: 3%; thickener: 19%; dispersant 6%; defoamer: 0.5%; preservative: 0.6%; leveling agent: 1.5%; %.

[0049] Mixed dry granules include: low temperature dry granules: 20%, medium temperature dry granules: 60%, high temperature dry granules: 20%. The chemical composition of the mixed dry granules includes: IL: 0.4%; SiO 2 : 60.8%; Al 2 o 3 : 11.6%; CaO: 9.4%; MgO: 1.1%; K 2 O: 5.1%; Na 2 O: 2.0%; ZnO: 6.6%; SrO: 2.5%; BaO: 0.5%. The particle gradation of the mixed dry granule is: 60-80 mesh: 11....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com