Top-loading washing machine

A washing machine and top-opening technology, which is applied to other washing machines, washing machines with containers, washing devices, etc., can solve the problems of inconvenient clothes, the inconvenience of the elderly or pregnant women, etc., and achieve the effects of simplifying the structure, improving cleanliness, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

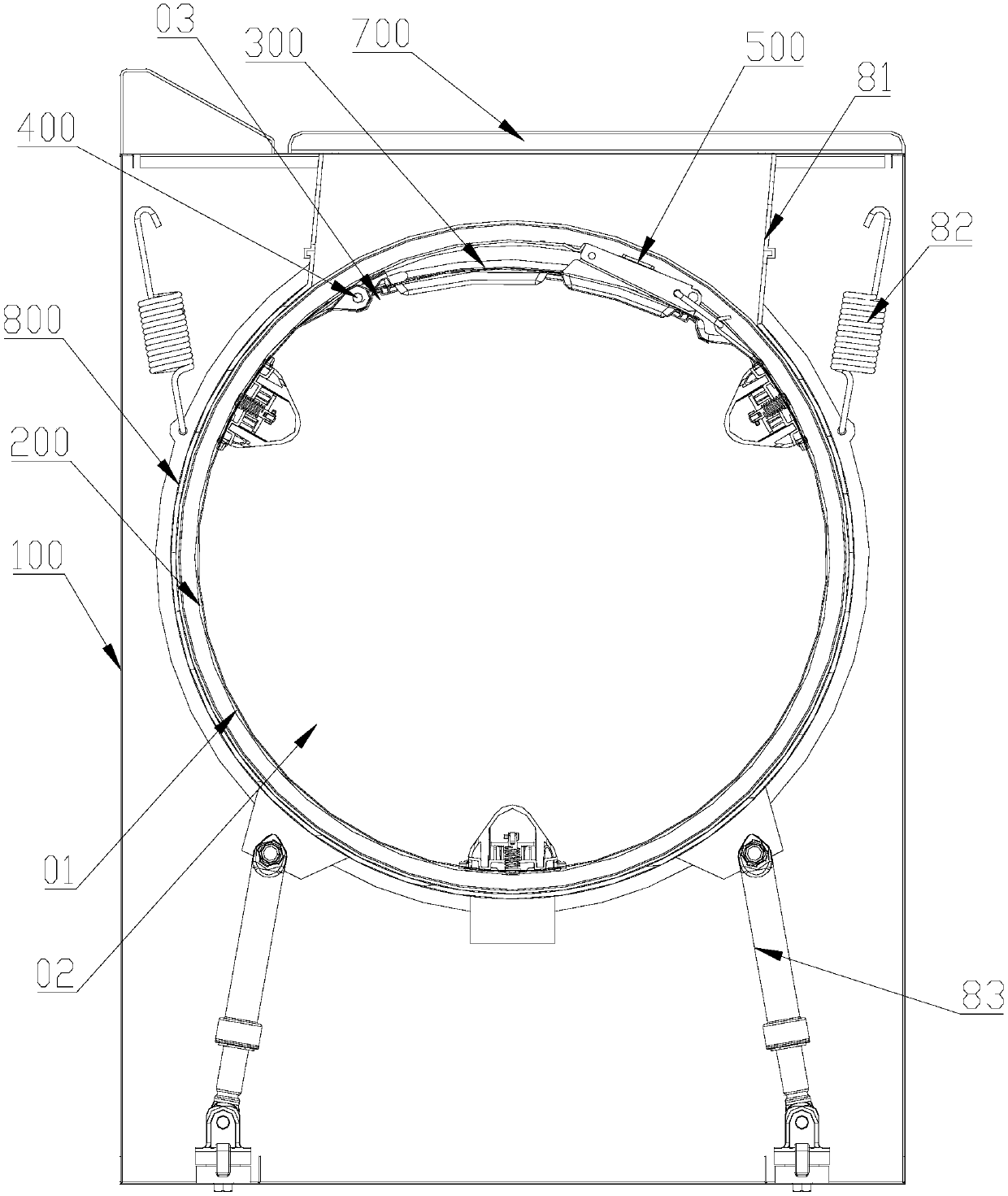

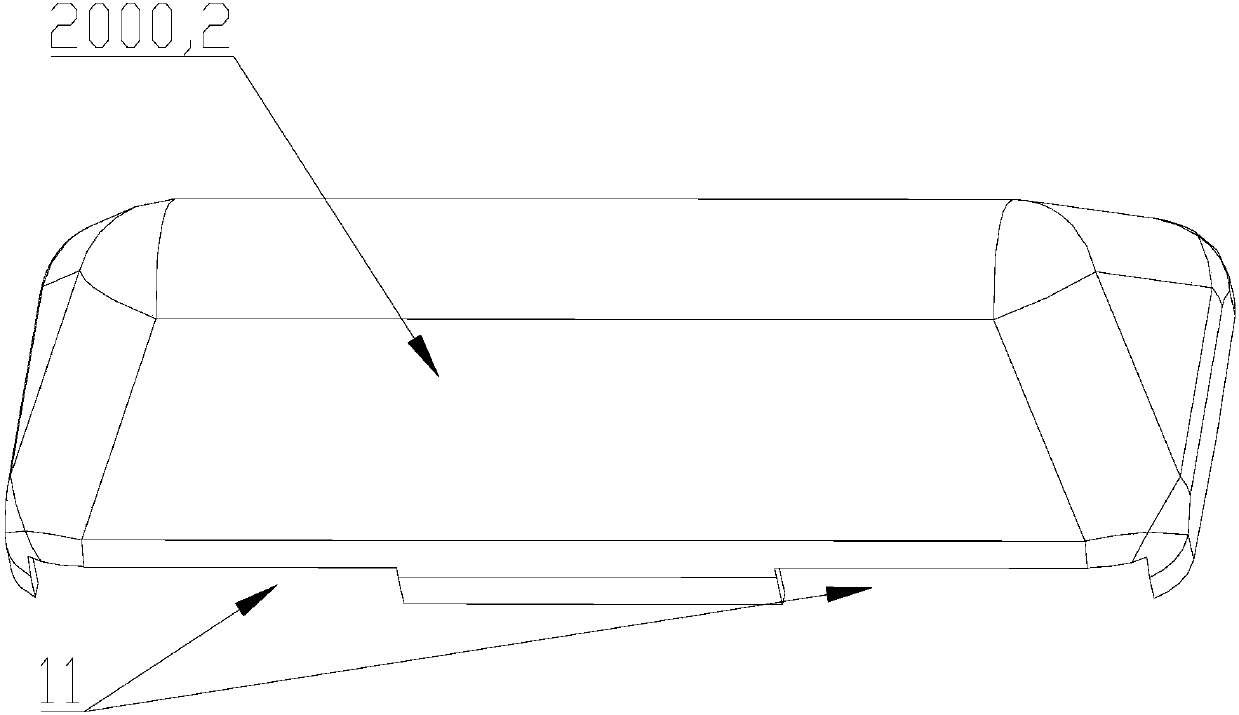

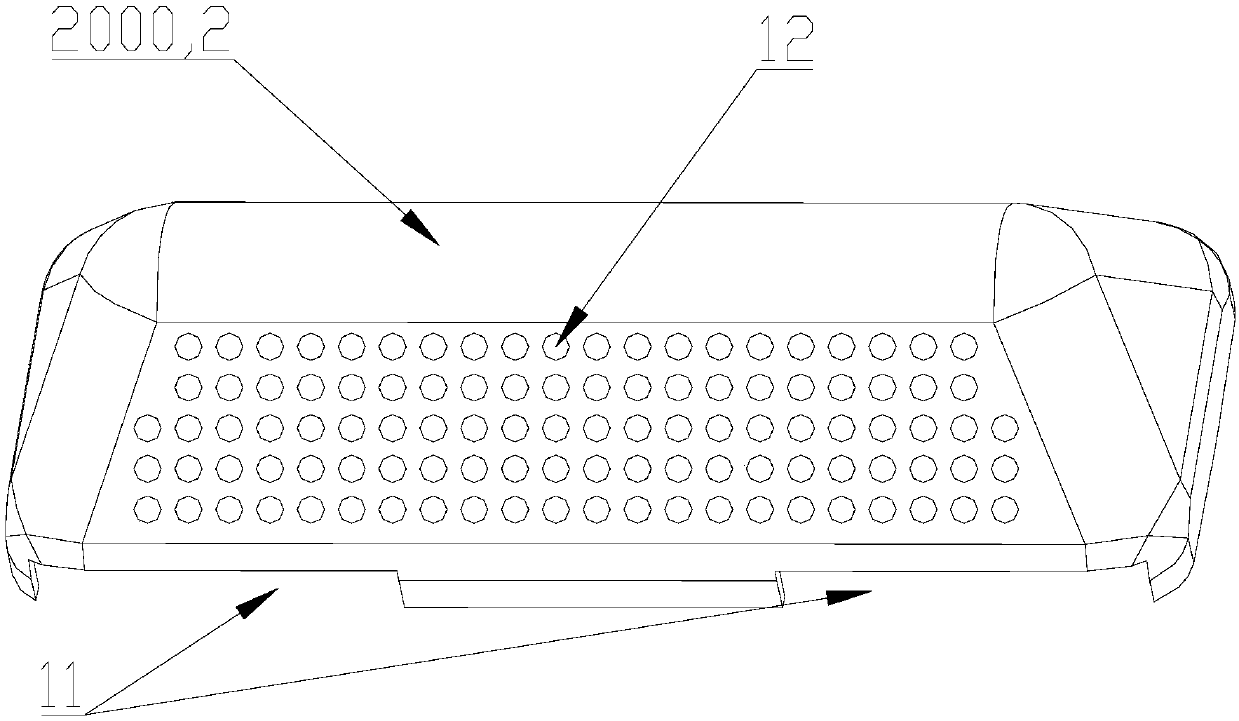

[0046] Such as figure 1 and Figure 8 As shown, the present embodiment introduces a washing machine. The side wall 01 of the drum 200 is provided with a clothes insertion opening 03, and the clothes insertion opening 03 is provided with a door body 300 which can be opened and closed.

[0047] By setting the clothes input port on the drum side wall of the washing machine, which can be opened and closed correspondingly through the door body, the purpose of users taking and placing clothes from the drum side wall is realized, and the overall structural layout of the drum washing machine is improved, which is convenient for users from top to bottom The purpose of observing the inside of the drum, and putting and taking clothes.

[0048] In this embodiment, the two ends of the cylindrical side wall 01 of the drum 200 are respectively sealed by the sealing portion 02, so that the drum forms a sealed cylindrical chamber. The drum 200 can be a sealed container that does not have a d...

Embodiment 2

[0052] Such as figure 1 and Figure 8 As shown, this embodiment introduces a washing machine, which includes a drum 200 installed in the housing 100, the axis of the drum 200 is arranged horizontally or inclined, and the side wall of the drum 200 is provided with a clothes insertion port 03, and the drum 200 is provided with The door body 300 that can turn over and open and close the clothes delivery port 03.

[0053] In this embodiment, the drum 200 includes a cylindrical side wall 01, and the two ends of the cylindrical side wall 01 are respectively sealed by corresponding side sealing parts 02, so that the drum 200 forms a cylindrical sealed container ; There is an opening on the cylindrical side wall 01, the opening constitutes the clothes insertion port 03, and the door body 300 can be turned outwards and opened correspondingly to cover the opening. Preferably, the axis of the drum 200 extends horizontally, and the two sealed ends of the drum 200 are respectively hinged...

Embodiment 3

[0060] Based on the second embodiment above, this embodiment also has the following technical features: figure 1 and 8 As shown, in this embodiment, the washing machine housing 100 is also provided with an outer cylinder 800, and the upper and lower ends of the outer cylinder 800 are respectively connected to the upper and lower parts of the washing machine housing through the hanging spring 82 and the support member 83, so that The outer cylinder 800 is installed inside the casing 100 to generate vibration displacement. The drum 200 is coaxially fitted inside the outer cylinder 800, and both ends of the outer cylinder 800 are sealed, so that the outer cylinder 800 forms a sealed container for receiving water from the washing machine.

[0061] In this embodiment, an opening is provided on the top of the side wall of the outer cylinder 800, and the opening is set opposite to the clothes inlet 3 provided on the side wall 1 of the drum, so that after the rotation of the drum 200...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com