Floor based on phase change material

A phase-change material and flooring technology, applied in the field of materials, can solve the problems of poor sound insulation performance of the floor and the inability to automatically adjust the temperature, etc., and achieve the effect of high heat storage efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

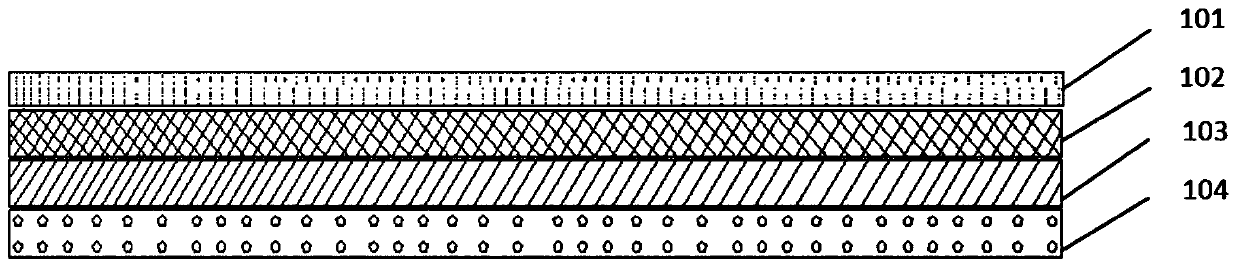

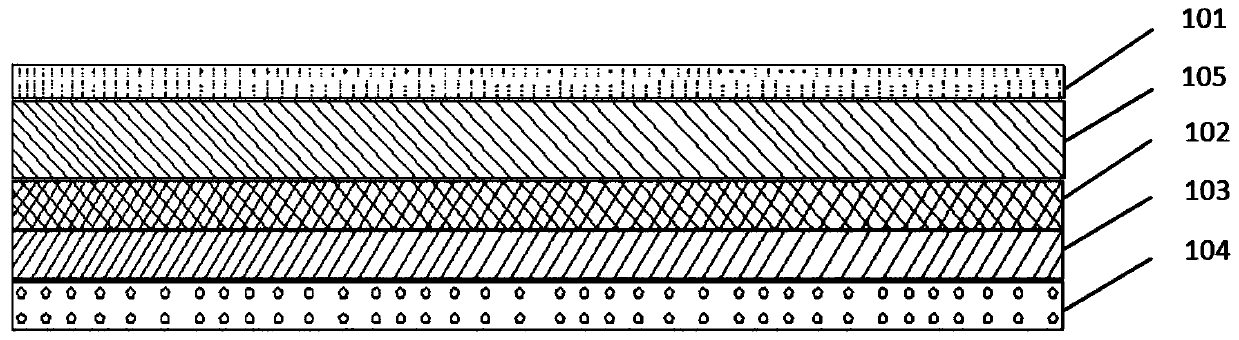

[0038] Please refer to figure 1 , an embodiment of the present invention provides a floor based on phase change materials, including:

[0039] Floor layer 101, phase change material layer 102, balanced heating layer 103, heat insulation material layer 104, temperature sensing device (not shown in the figure) and temperature control device (not shown in the figure);

[0040] The floor layer 101 is arranged on the surface layer, the heat insulating material layer 104 is arranged on the bottom layer, the balanced heating layer 103 is arranged above the heat insulating material layer 104, and the phase change material layer 102 is arranged on the floor Between the layer 101 and the balanced heating layer 103;

[0041] The temperature sensing device is arranged below the floor layer, and the temperature sensing device and the balanced heating layer are electrically connected to the temperature control device respectively.

[0042] In the embodiment of the present invention, the f...

Embodiment 2

[0051] In practical applications, phase change materials generally use solid-liquid conversion materials. This kind of material has a liquid phase during the phase change process, which is easy to leak, pollute the environment, and affect the phase change effect; In the process, a liquid phase is generated, and the floor made of it has poor heat resistance and aging resistance, which affects the service life of the composite floor.

[0052] Aiming at the above problems, the embodiment of the present invention proposes corresponding solutions, including:

[0053] The preparation materials of the phase change material layer include: phase change powder and adsorption carrier;

[0054] The phase change powder includes: at least one of paraffin wax, polyethylene wax, polypropylene wax or alkane wax;

[0055] The adsorption carrier includes: graphite or aerogel.

[0056]If the adsorption carrier is graphite, the graphite is worm-like expanded graphite; for every 100 parts by weig...

Embodiment 3

[0062] In the prior art, the heating layer and the heat conduction layer are set separately, resulting in a thicker floor structure. The embodiment of the present invention adopts the solution of balancing the heating layer, including:

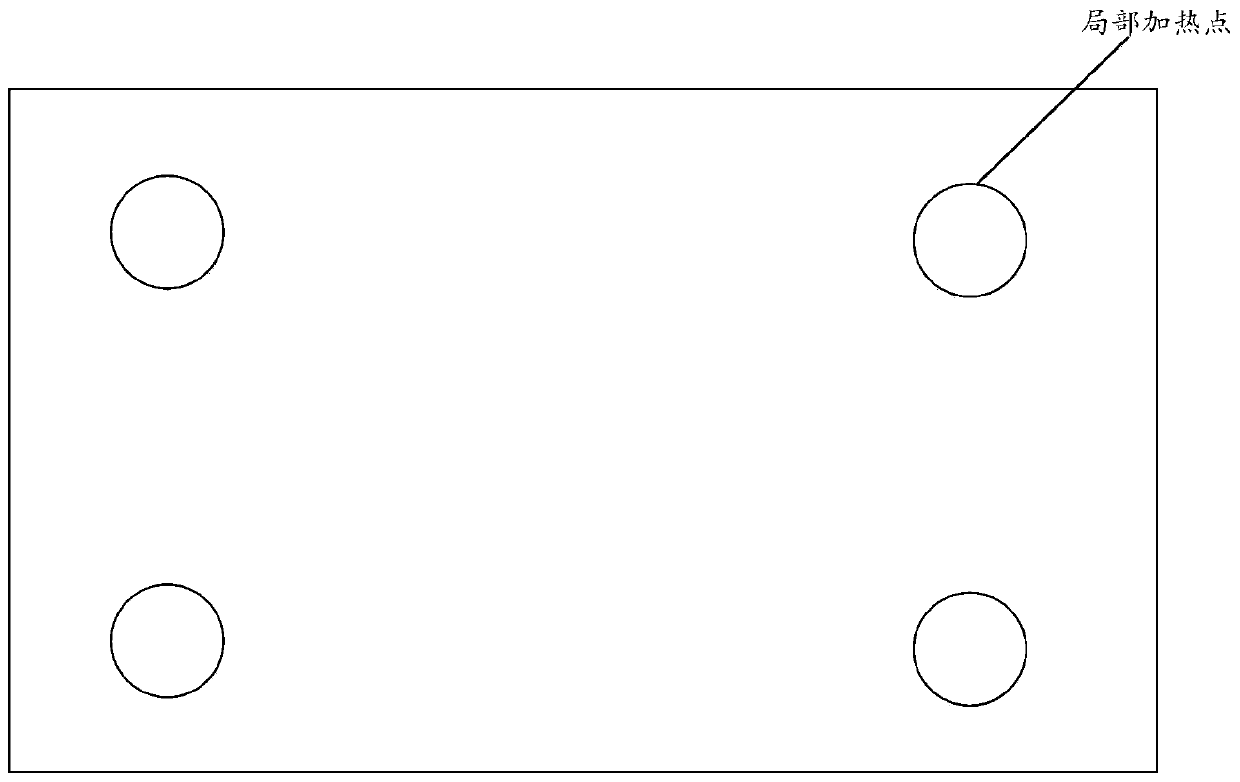

[0063] see figure 2 , in the embodiment of the present invention, the balanced heating layer includes: local heating points and heat uniform materials; wherein, the local heating points include M, and M is an integer greater than or equal to 2; specifically, the local heating points Heating points can be set at the four corners of the balanced heating layer (such as figure 2 shown), or, in order to make the heating more balanced, in addition to the four corners, a local heating point can also be set in the middle of the balanced heating layer. Specifically, the local heating point can be a heating wire structure, and the heat-spreading material has an insulating function, and the heat-spreading material is set by wrapping the local heating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com