Detection system with effect of overcoming temperature rise of hydraulic oil in hydraulic detecting process

A technology of hydraulic detection and detection system, applied in the direction of fluid pressure actuation system test, measurement force, measurement device, etc., can solve the problems of hydraulic pump temperature rise, hydraulic oil temperature rise, affecting the detection accuracy of detection system, etc. The effect of temperature rise, avoiding oil temperature rise, and stabilizing ampere force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

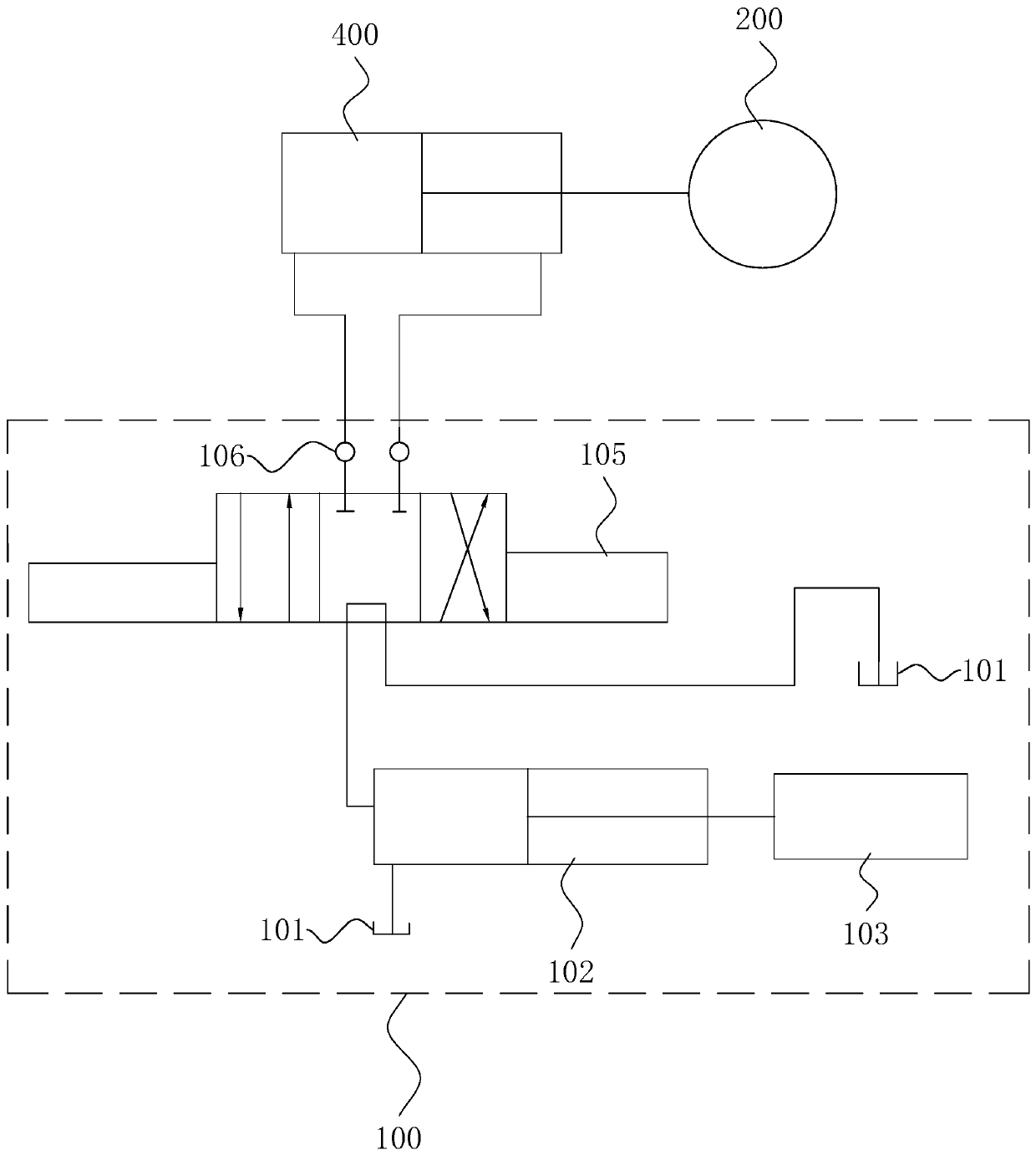

[0038] Embodiment: a detection system that overcomes the temperature rise of hydraulic oil in the hydraulic detection process, such as figure 1 As shown, the oil supply device 100 and the measurement and control device 200. The oil supply device 100 delivers hydraulic oil to the hydraulic cylinder under test to provide hydraulic pressure for the hydraulic cylinder 400 under test. The piston rod of the hydraulic cylinder 400 under test is in contact with the detection end of the measurement and control device 200. When the hydraulic cylinder 400 under test expands and contracts under the pressure of the hydraulic oil, it will exert a thrust or pull on the measurement and control device 200, thereby detecting the hydraulic cylinder under test at this time. 400 generated thrust.

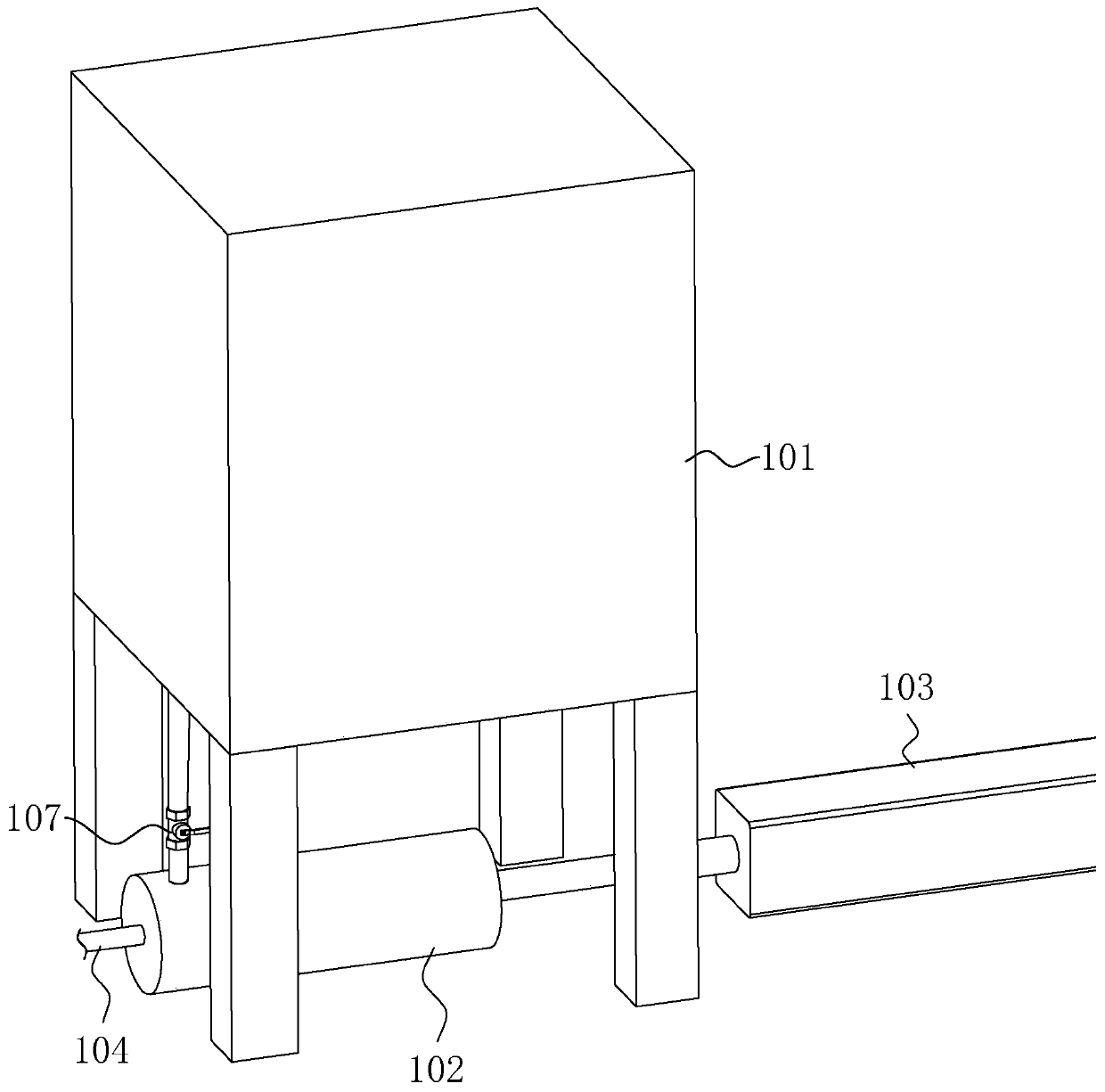

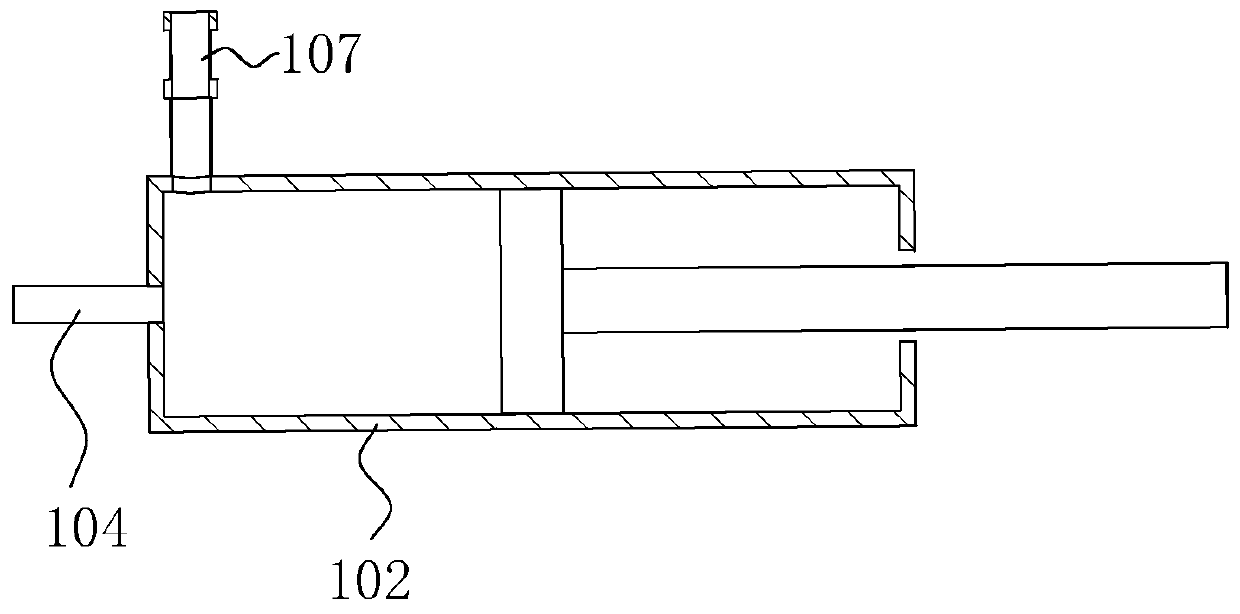

[0039] Such as figure 1 As shown, the oil supply device 100 includes an oil storage tank 101 for oil storage, a single-acting piston cylinder 102 and a driving structure 103 for driving the single-act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com