High-reliability and high-self-locking-capacity calibration mechanism

A reliable and self-locking technology, which is applied in the direction of measuring devices and instruments, can solve the problems of complex worm gear assembly process, affecting the stability of optical and mechanical structures, and unfavorable mass production, etc., achieving good self-locking and high reliability , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0030] The present invention will be described in detail below with reference to the accompanying drawings and examples.

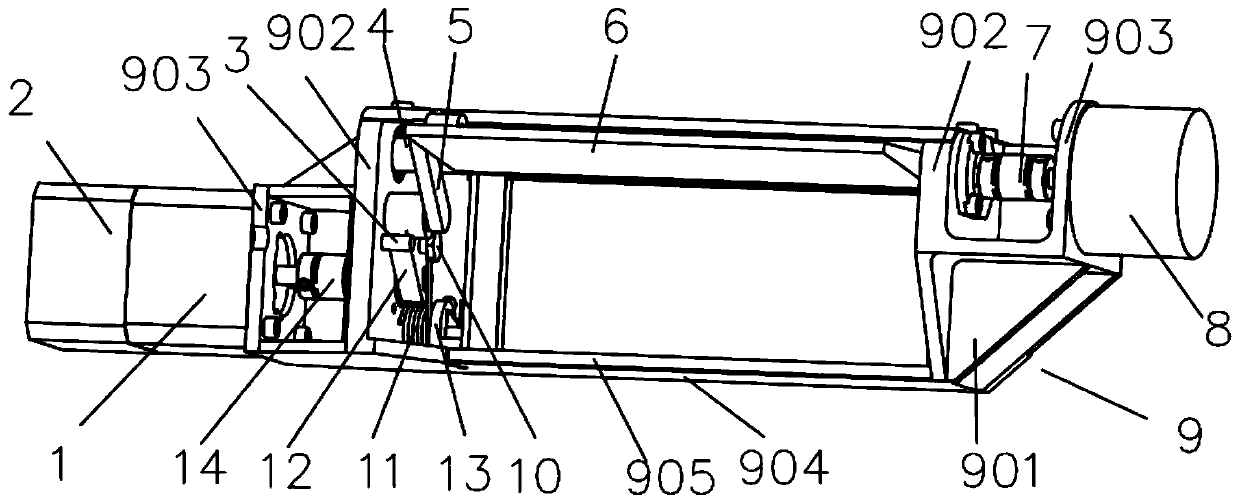

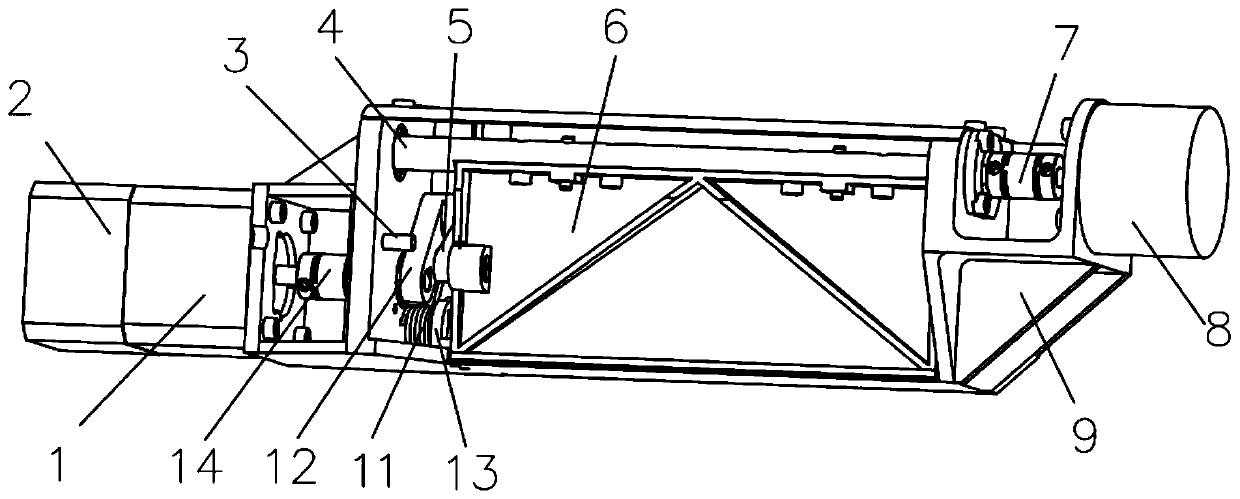

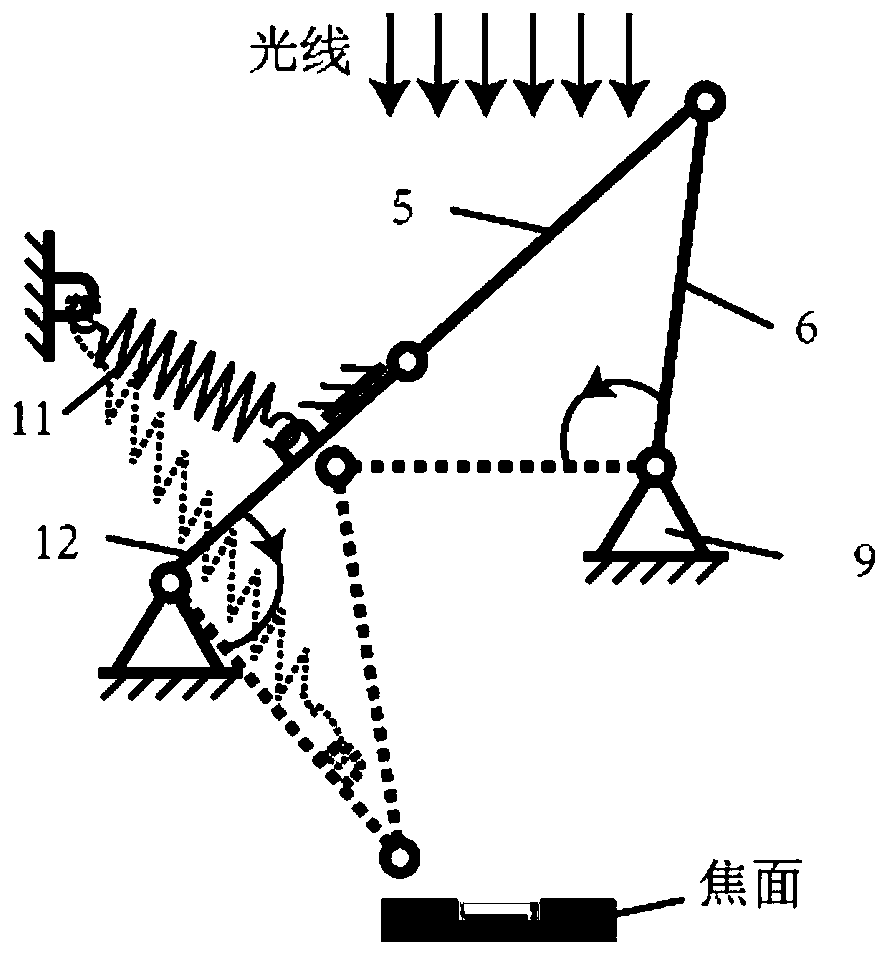

[0031] like Figure 1-Figure 3 As shown, a calibration mechanism with high reliability and high self-locking ability includes a drive assembly, an execution assembly and a feedback assembly arranged on the base 9. The drive assembly drives the opening and closing of the execution assembly, and the feedback assembly feeds back The rotation angle of the execution assembly, the drive assembly and the feedback assembly are arranged on opposite sides of the execution assembly, and the drive assembly is also equipped with a brake 2;

[0032] The executive assembly includes a calibration plate 6, the bottom of the calibration plate 6 is fixed on the major axis 4, and the major axis 4 is rotata...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap