Oil pumping power device and mounting method

A power plant and oil pumping technology, applied in the field of electric motors, can solve problems such as easily damaged electric motors, and achieve the effects of preventing bearing damage, increasing contact area, and reducing impact damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

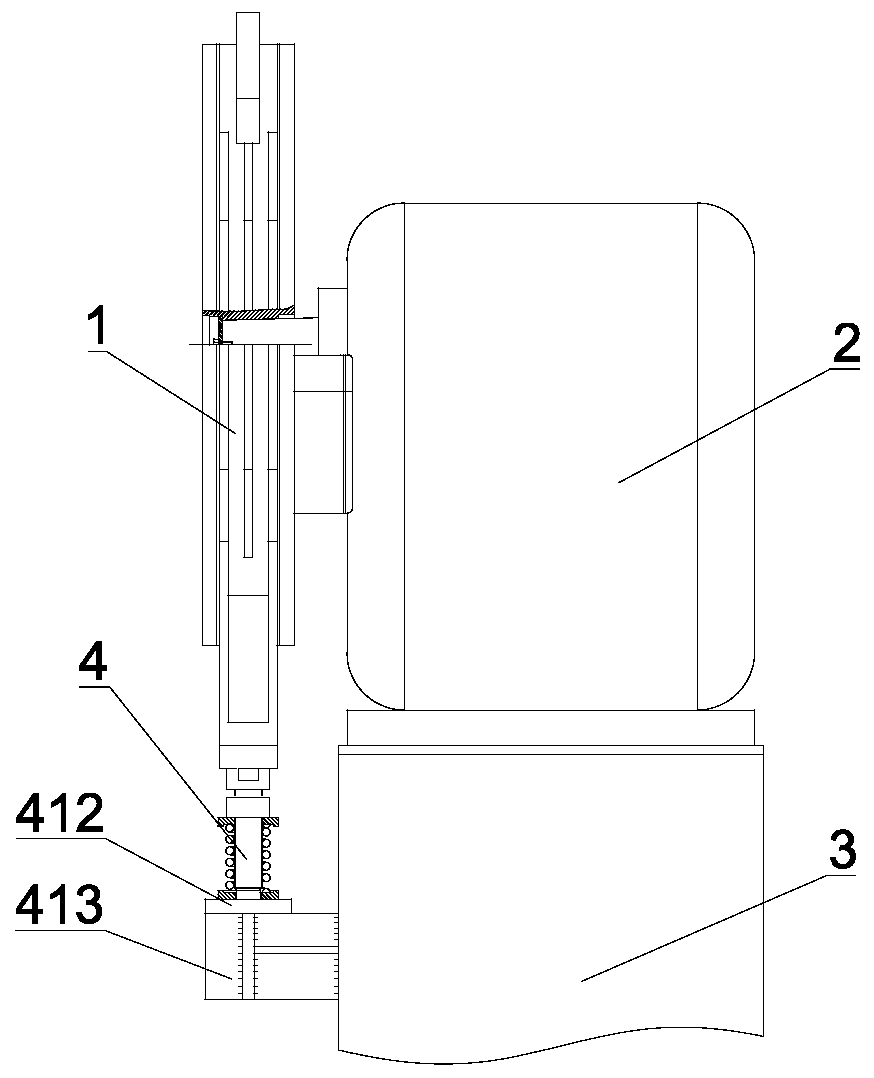

[0033] Such as figure 1 As shown, it is a schematic diagram of the structure position of the present invention in the front view. The disc frequency conversion motor 1 is directly connected to the reducer 2, and is directly installed on the shaft of the reducer 2 through the hollow shaft of the disc frequency conversion motor 1, and the reducer 2 is installed On the upper end of the pumping unit installation frame 3, the lower end of the disc frequency conversion motor 1 is equipped with an oil pumping power device 4, and the lower end of the oil pumping power device 4 is provided with a support plate 412 and a rib plate 413, and the support plate 412, the rib plate 413 and the oil pumping The machine mounting frame 3 is fixedly connected, and the rib plate 413 is fixedly connected to the bottom of the support plate 412 for auxiliary support of the support plate 412 .

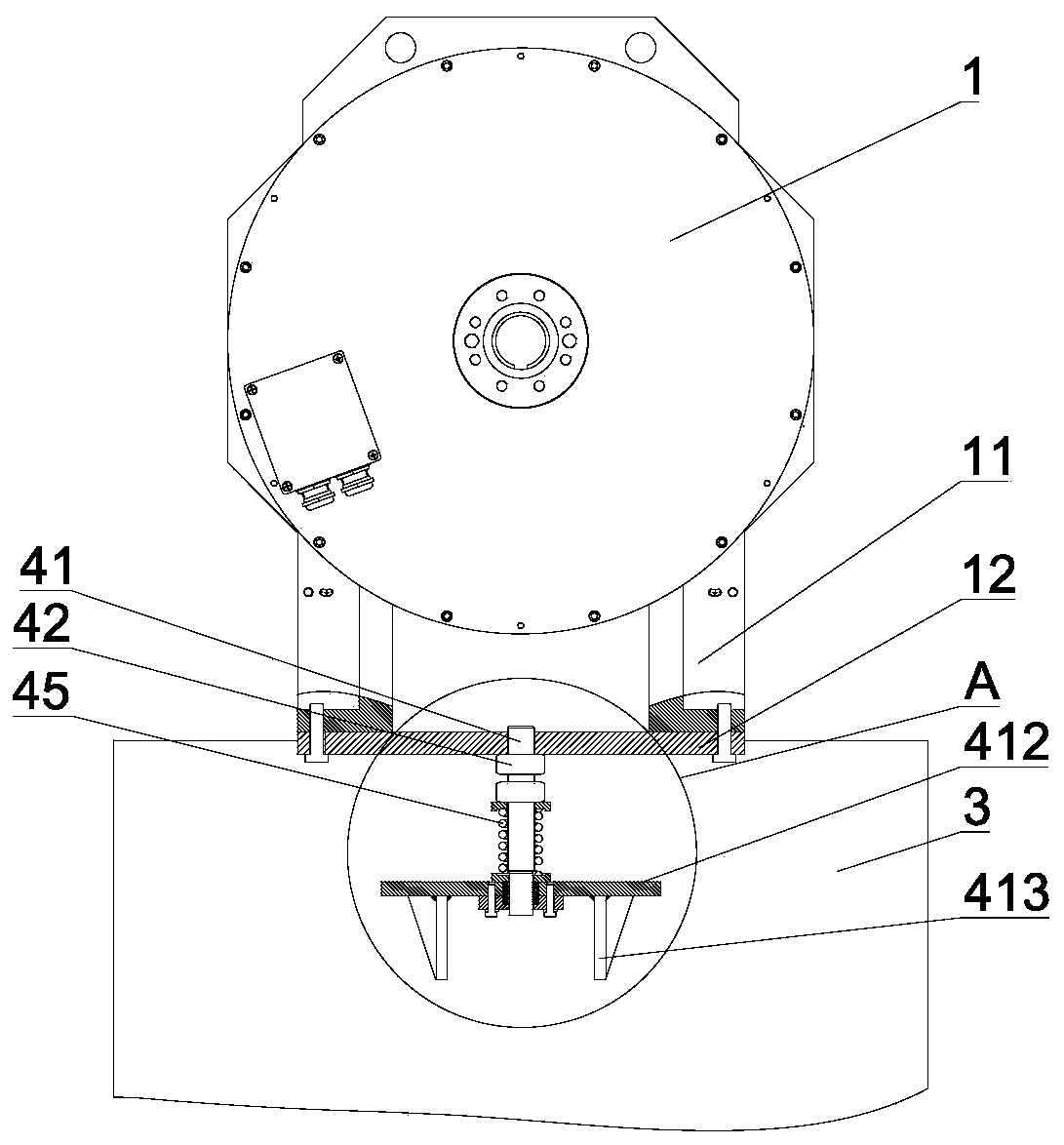

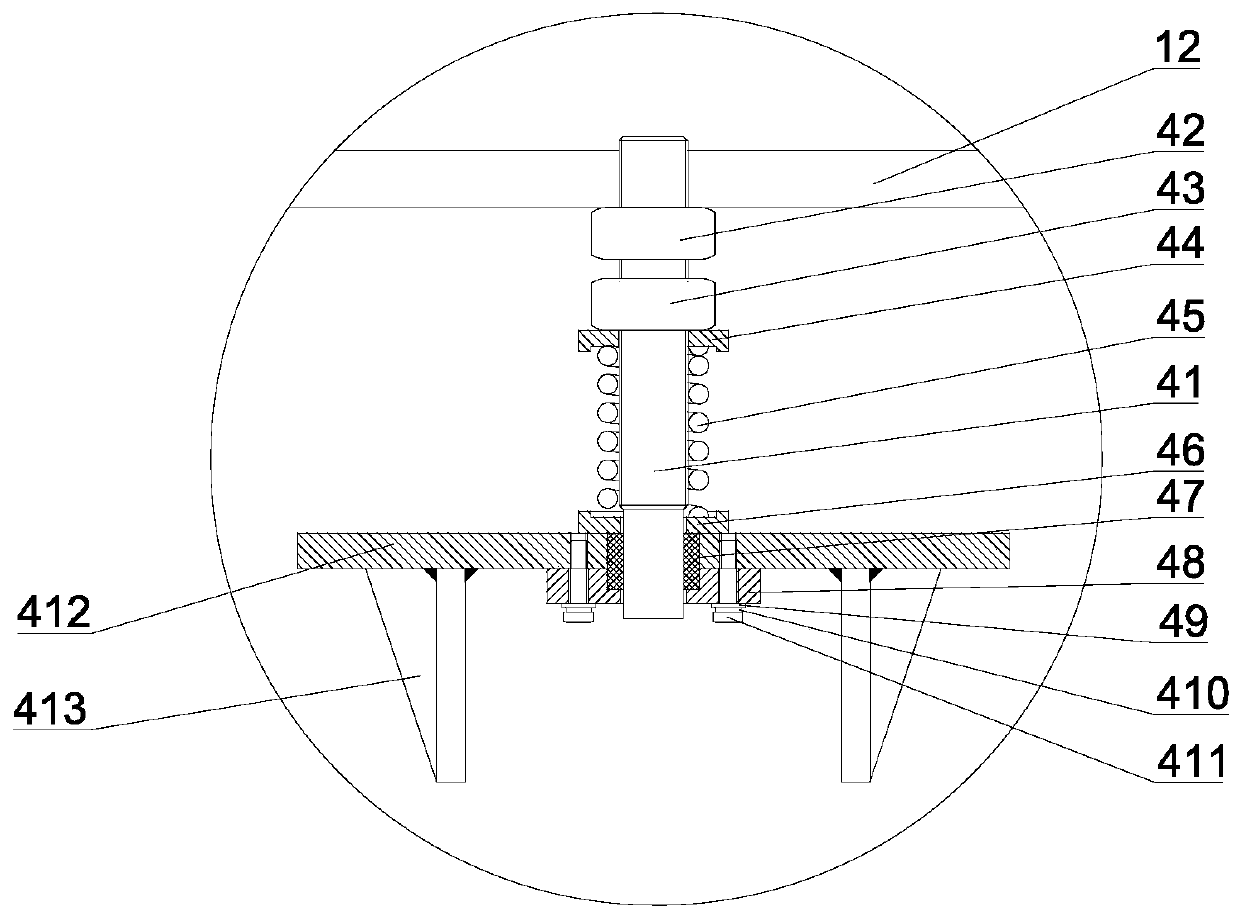

[0034] Such as Figure 2-Figure 3 As shown, it is the left view of the installation state of the I-type dis...

Embodiment 2

[0038] Such as Figure 4-Figure 5 As shown, it is the left view of the installation state of the type II disc frequency conversion motor. The difference between the motor installation device 4 and the embodiment 1 is that there are two sets of adjustment shafts 41, nuts I 42, nuts II 43, spring pressure plates 44, damping springs 45, springs Backing plate 46, shock-absorbing rubber sleeve 47 and fixing plate 48 are respectively fixed on the same supporting plate 412 through corresponding washers 49, spring washers 410 and outer hexagonal bolts II 411; Type variable frequency motor foot 11.

[0039]The invention is reasonable and simple in structure, convenient and flexible in use, convenient and practical, and is suitable for pumping units in oil fields. The characteristics of the patent of the present invention are: the disc-type variable frequency motor 1 is directly installed on the shaft of the reducer 2, and the use of spring support has two advantages. The first is that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com