Washing machine and distributor box thereof

A dispenser box, washing machine technology, applied in the washing machine field, to achieve the effect of improving user experience, shortening length, and reducing moisture residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

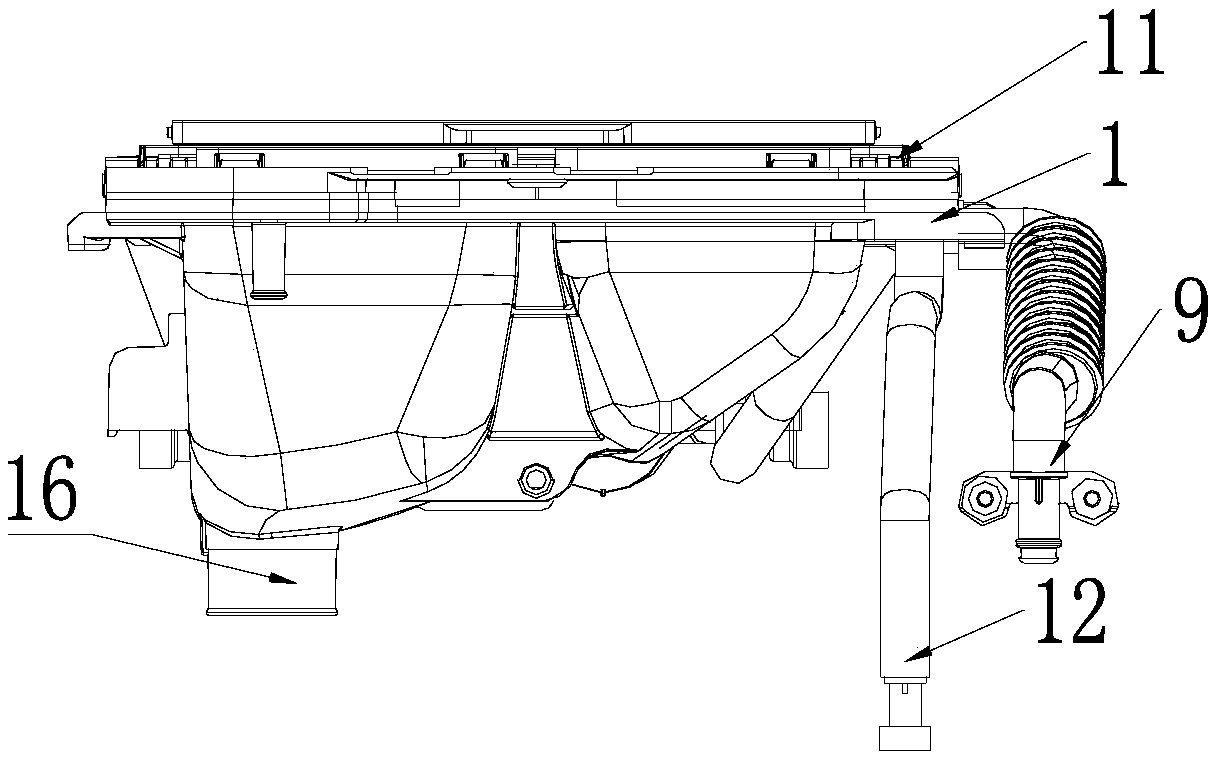

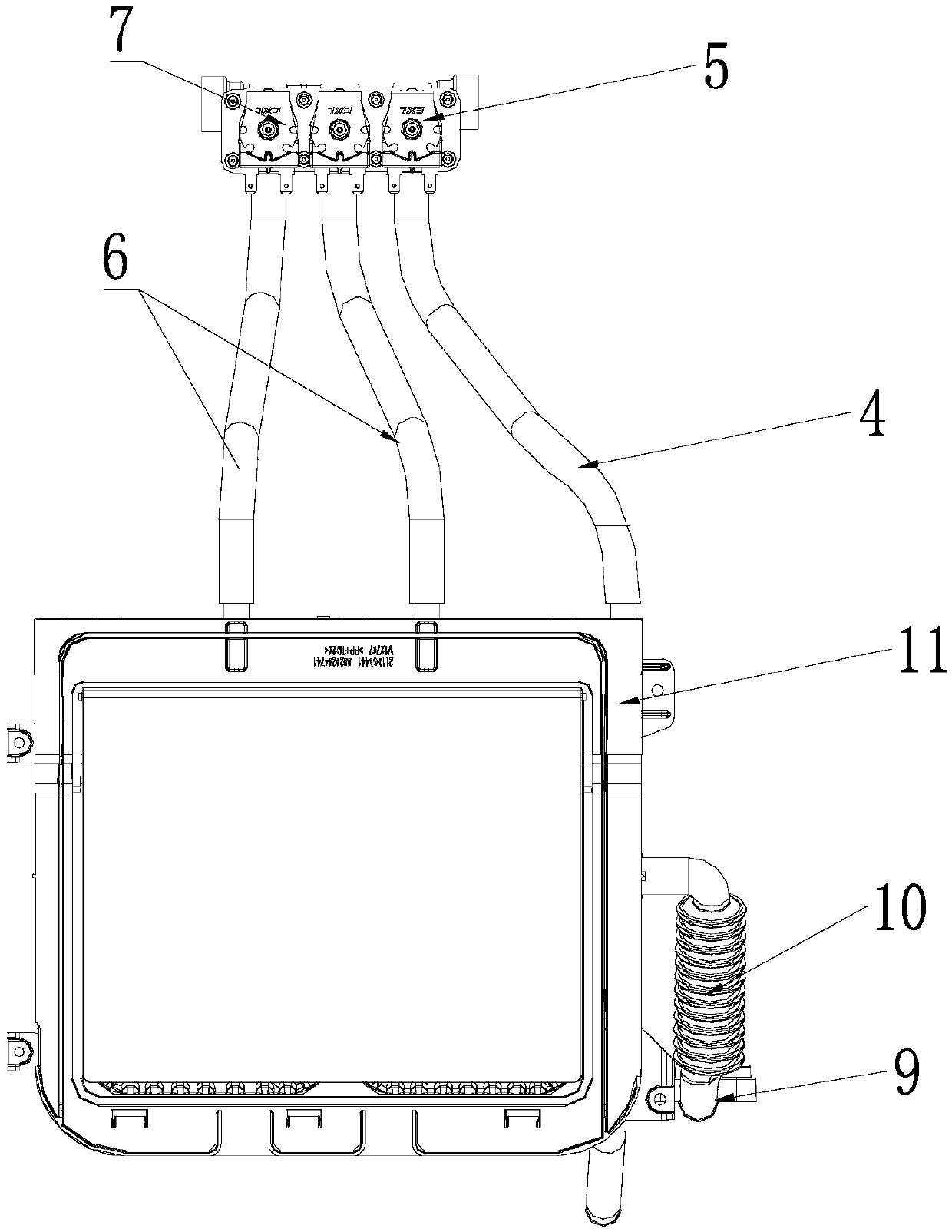

[0044] Such as Figure 1-6As shown, a distributor box of a washing machine is provided with a first water inlet 13 and a first water outlet 15 communicating with the cavity channel 2 and a second water inlet 14 and a second water outlet communicating with the accommodating chamber 3 on the distributor box. The water outlet 16, the cavity channel 2 receives water through the first water inlet 13, the first water outlet 15 drains, the accommodating chamber 3 receives water through the second water inlet 14, and the second water outlet 16 drains water.

[0045] The washing water enters the cavity channel 2 through the first water inlet 13, and is discharged through the first water outlet 15, and the washing water enters the accommodation chamber 3 through the second water inlet 14, and is discharged through the second water outlet 16, so that the accommodation chamber 3 and the The cavity channel 2 can respectively enter and discharge water, and the two processes do not interfere...

Embodiment 2

[0054] Such as Figure 1-6 As shown, a washing machine includes a tank body and a water inlet pipe and a distributor box arranged in the tank body. The distributor box has a cavity channel 2 and an accommodating cavity 3 for accommodating laundry treatment agents. The accommodating cavity 3 and the cavity The channels 2 are all connected with the water inlet pipeline, and the water inlet pipeline can respectively feed water into the accommodation cavity 3 and the cavity channel 2, and the accommodation cavity 3 and the cavity channel 2 can drain water respectively.

[0055] In the control scheme of the washing machine, the washing machine controls the conduction between the water inlet pipeline and the cavity channel 2, enters the water into the cavity channel 2, and discharges the washing water through the cavity channel 2, and the washing machine controls the conduction between the water inlet pipeline and the accommodating cavity 3, and flows into the cavity channel 2. Wate...

Embodiment 3

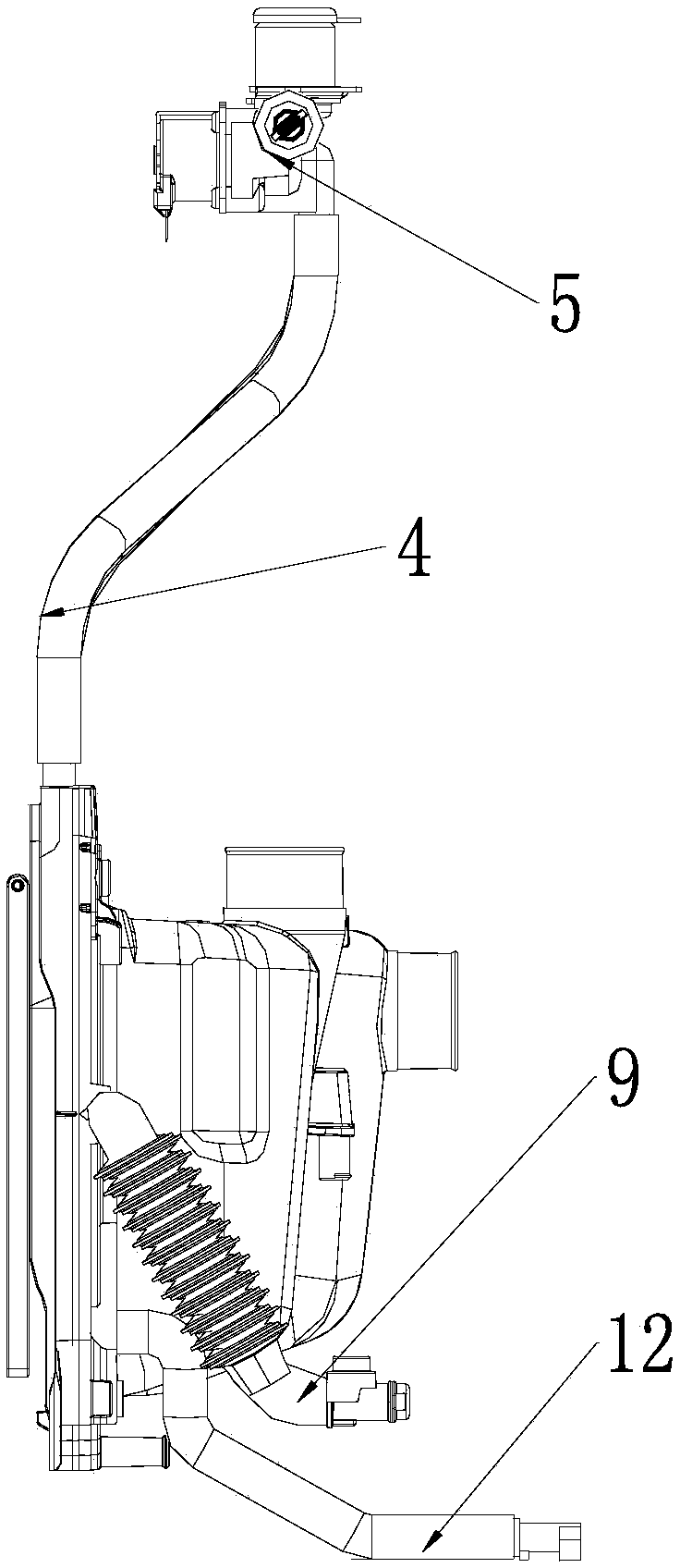

[0068] Such as Figure 1-6 As shown, this embodiment is a specific solution of Embodiment 1 and Embodiment 2. A drum washing machine includes a cabinet and a first spray pipe 9, a second spray pipe 12, and a first spray pipe 12 arranged in the cabinet. A water inlet pipe 4, two second water inlet pipes 6 and a distributor box.

[0069] The dispenser box has a cavity channel 2 and two accommodating cavities 3 for accommodating laundry treatment agents, and the accommodating cavities 3 are isolated from the cavity channel 2 . The distributor box is provided with a first water inlet 13 and two first water outlets 15 communicating with the cavity channel 2 and a second water inlet 14 and second water outlets 16 respectively communicating with the two containing chambers. One of the first water outlets 15 is set close to the middle of the cavity channel 2 , and the other first water outlet 15 is set away from the first water inlet 13 .

[0070] The first water inlet pipe 4 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com