Spin-type air filter device

An air filter, spin-type technology, applied in the direction of fuel air filter, combustion air/combustion-air treatment, charging system, etc., can solve the problems of shortened filter life, manual cleaning, airflow impact damage, etc. To achieve the effect of long service life, prolonging service life and reducing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

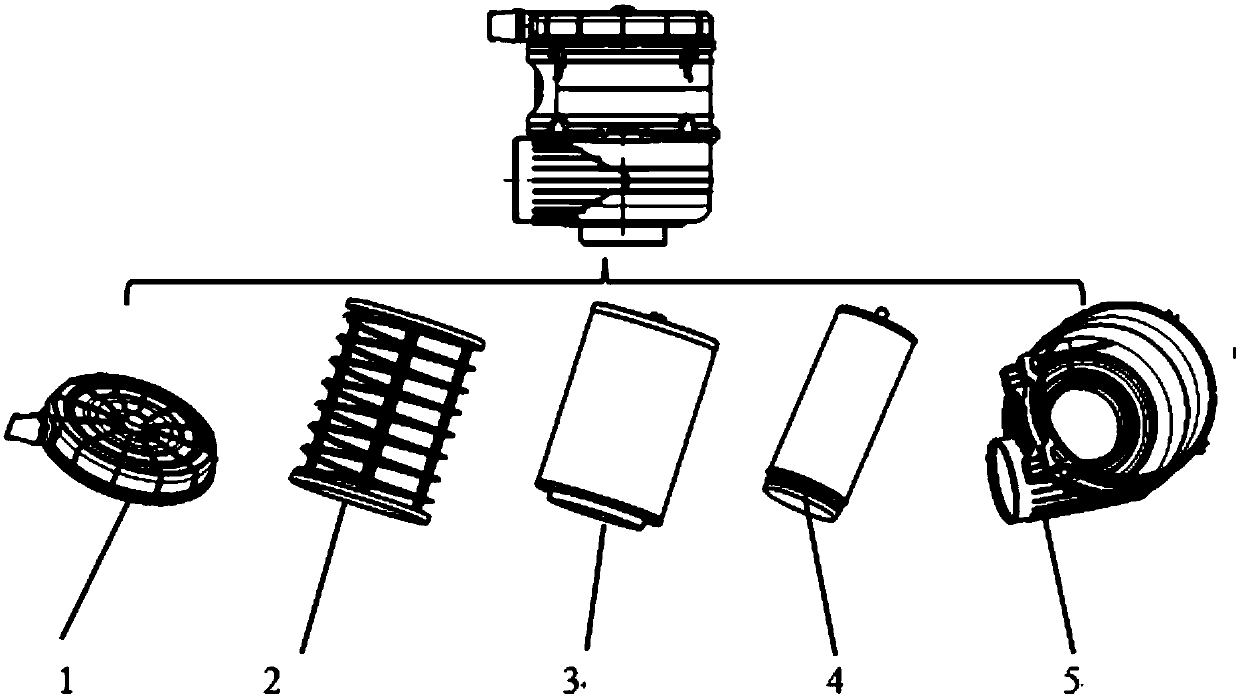

[0033] A spin-type air filter device, the structure of which is as follows figure 1 As shown, it includes upper end cover assembly 1, swirl plate 2, main filter element assembly 3, safety filter element assembly 4, and lower end cover assembly 5.

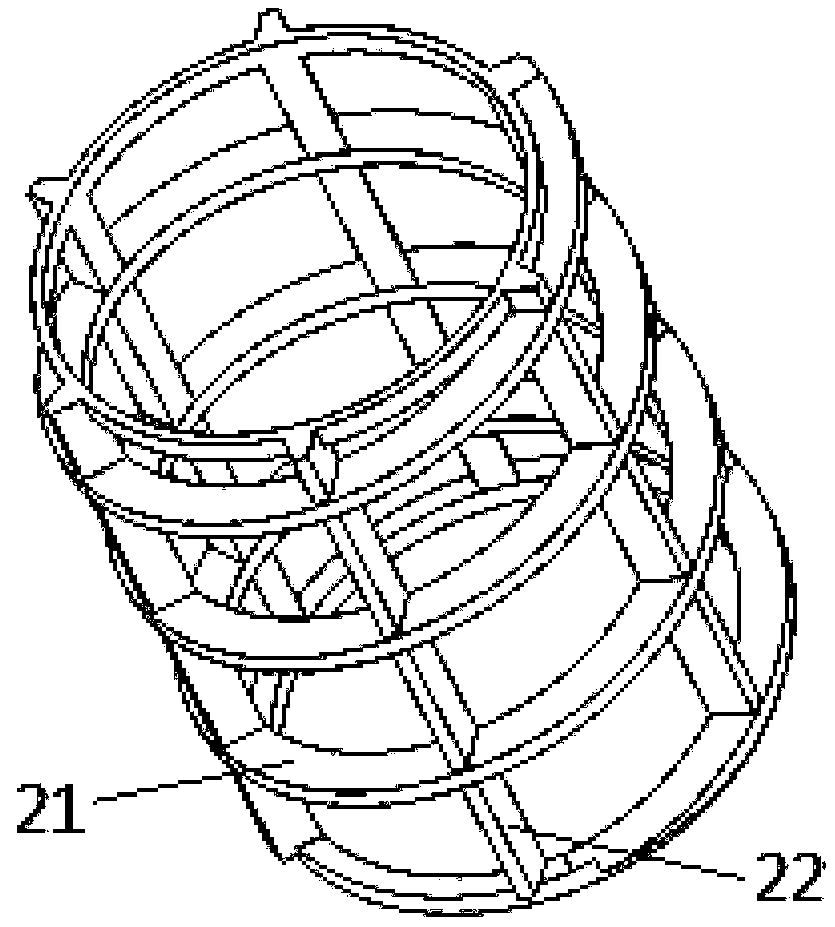

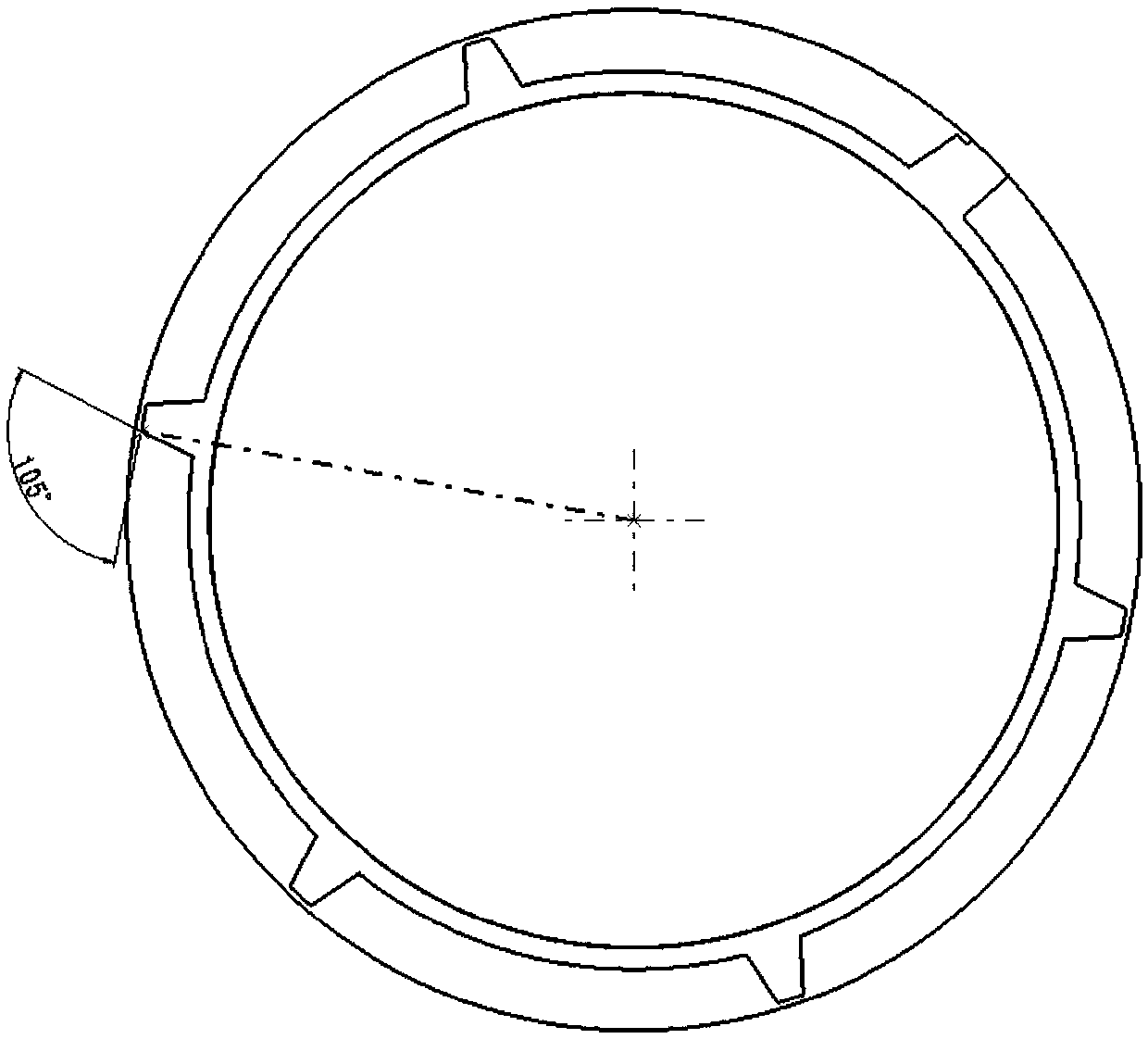

[0034] figure 2 , image 3 and Figure 4 Both are schematic diagrams of the structure of the swirl sheet, the swirl sheet 2 is integrally injected, and can be detachably mounted on the outside of the main filter element assembly 3 for easy reuse. The swirl vane 2 includes a spiral blade structure 21 and a baffle 22, wherein the baffle 22 is a cylindrical distribution frame structure; The external fixed connection; the rotation angle of the helical blade structure is 15°; the included angle between the baffle and the air intake is 105°; the helical blade structure 21 extends from one end of the baffle 22 to the other end.

[0035] Figure 5 It is a structural schematic diagram of the upper end cover assembly, the upper end cove...

Embodiment 2

[0042] A spin-type air filter device, the structure of which is as follows figure 1 As shown, it includes upper end cover assembly 1, swirl plate 2, main filter element assembly 3, safety filter element assembly 4, and lower end cover assembly 5.

[0043] The structure of the upper end cover assembly 1, the main filter element assembly 3, the safety filter element assembly 4, and the lower end cover assembly 5 of the spin-type air filter device is the same as that in embodiment 1, the difference is that in embodiment 2 The structural parameters of the swirl vanes are different from those of the swirl vanes in Example 1.

[0044] In Embodiment 2, the swirl plate is integrally injection-molded, and can be detachably mounted on the outside of the main filter element assembly, which is convenient for repeated use. The swirl vane includes a spiral blade structure and a baffle, wherein the baffle is a cylindrical distribution frame structure; the spiral blade structure is arranged ...

Embodiment 3

[0046] A spin-type air filter device, the structure of which is as follows figure 1 As shown, it includes upper end cover assembly 1, swirl plate 2, main filter element assembly 3, safety filter element assembly 4, and lower end cover assembly 5.

[0047] The structure of the upper end cover assembly 1, the main filter element assembly 3, the safety filter element assembly 4, and the lower end cover assembly 5 of the spin-type air filter device is the same as that in embodiment 1, the difference is that in embodiment 3 The structural parameters of the swirl vanes are different from those of the swirl vanes in Example 1.

[0048] In Embodiment 3, the swirl sheet is integrally injection-molded, and can be detachably mounted on the outside of the main filter element assembly, which is convenient for repeated use. The swirl vane includes a spiral blade structure and a baffle, wherein the baffle is a cylindrical distribution frame structure; the spiral blade structure is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com