Dense storage container scheduling method and device and electronic equipment

A technology of electronic equipment and scheduling method, applied in the direction of instruments, data processing applications, forecasting, etc., can solve problems such as blocking robots, reducing operating efficiency, and robot jams, so as to solve jams or deadlocks, improve operating efficiency, avoid conflicts and disordered effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

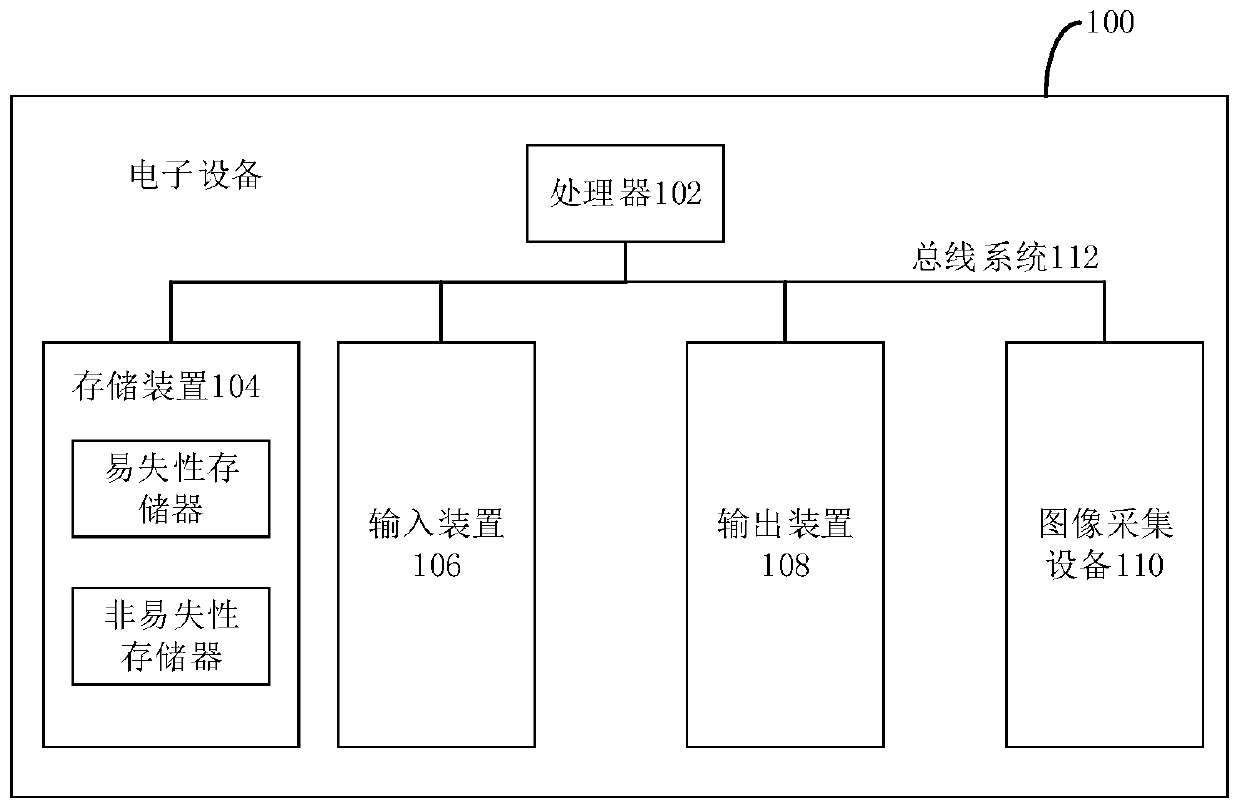

[0037] First, refer to figure 1 An example electronic device 100 for implementing the dense storage container scheduling method, device, electronic device and warehouse management system according to the embodiments of the present invention will be described.

[0038] Such as figure 1 Shown is a schematic structural diagram of an electronic device, the electronic device 100 includes one or more processors 102, one or more storage devices 104, an input device 106 and an output device 108, and may also include one or more image acquisition devices 110 , these components are interconnected via bus system 112 and / or other forms of connection mechanisms (not shown). It should be noted that figure 1 The components and structure of the electronic device 100 shown are only exemplary and not limiting. According to needs, the electronic device may also have other components and structures, or the electronic device may also have fewer components than those shown in the figure. For exa...

Embodiment 2

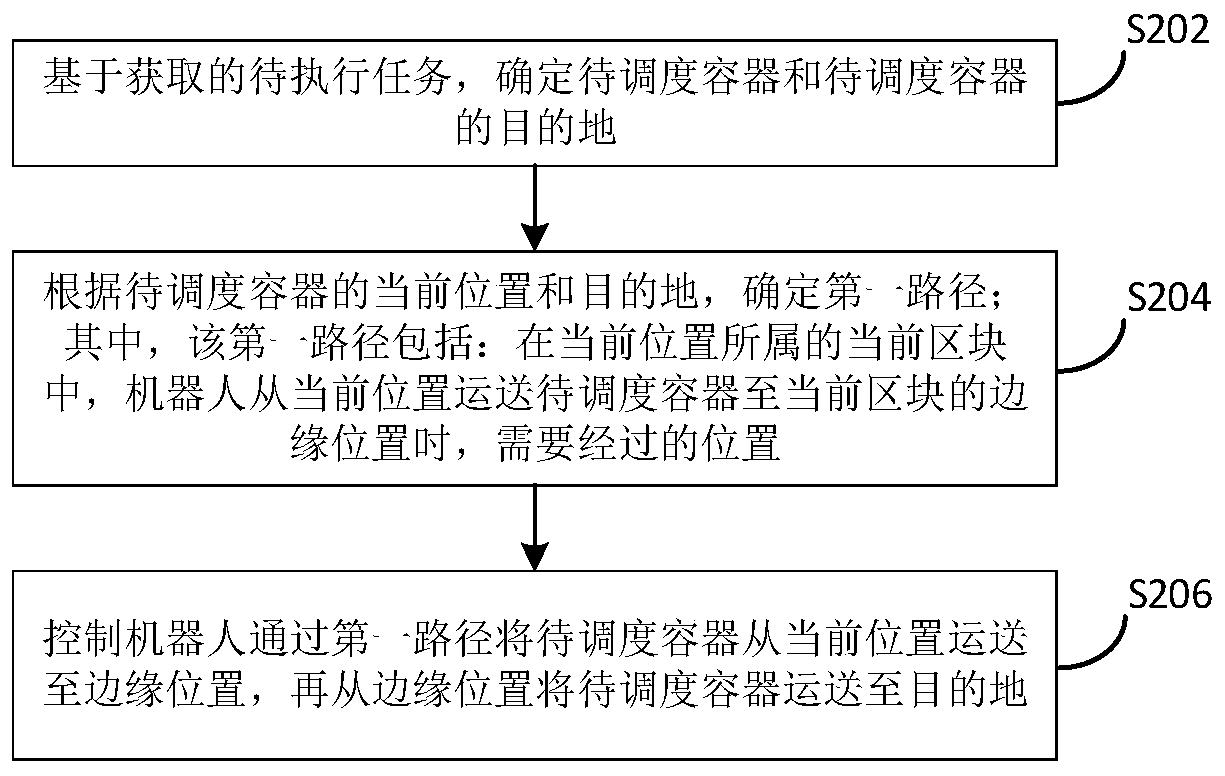

[0046] This embodiment provides a container scheduling method for intensive storage, the method is applied to electronic equipment; the electronic equipment communicates with the robot; the container is placed in the block; multiple containers at the edge of the block are surrounded by the inside of the block container at the location; the robot is used to transport the container to the destination; eg figure 2 As shown, the method includes the following steps:

[0047] Step S202, based on the acquired task to be executed, determine the container to be scheduled and the destination of the container to be scheduled;

[0048] The tasks to be executed above can be tasks sent by users using computers, tablet computers, mobile phones, or wearable devices through applications such as webpages and shopping apps; they can also be tasks that are manually input in large quantities, such as bulk cargo tasks, etc. ; It can also be a task generated by the control system of the warehouse ...

Embodiment 3

[0060] This embodiment provides another intensive storage container scheduling method, which is implemented on the basis of the above embodiments; this embodiment focuses on determining the container to be scheduled and the destination of the container to be scheduled based on the preset tasks to be executed specific process; such as Figure 5 As shown, the intensive storage container scheduling method of this embodiment includes the following steps:

[0061] Step S502, according to the task information of each task in the preset task pool, obtain available tasks from the task pool; wherein, the task information includes: task content, task status, task execution time and dependent tasks;

[0062] The aforementioned preset task pool usually includes all the tasks that the robot needs to perform, and the tasks may be independent of each other or may have dependencies. For tasks with dependencies, dependent task scheduling is required, that is, the dependent tasks are executed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com