Grouting material and local fractured formation inclined shaft inverse well guide hole drilling technology using the same

A grouting material and stratum technology, which can be used in earth-moving drilling, directional drilling, wellbore/well components, etc., can solve problems such as toxic and harmful components, reduce labor intensity, shorten solidification time, and improve synergy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

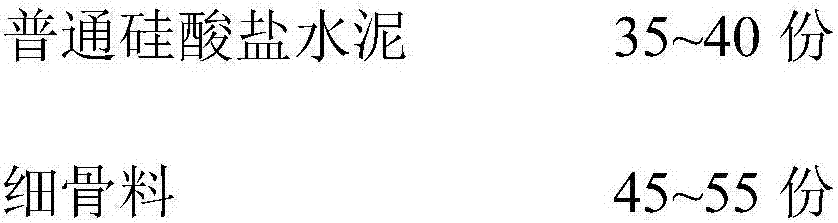

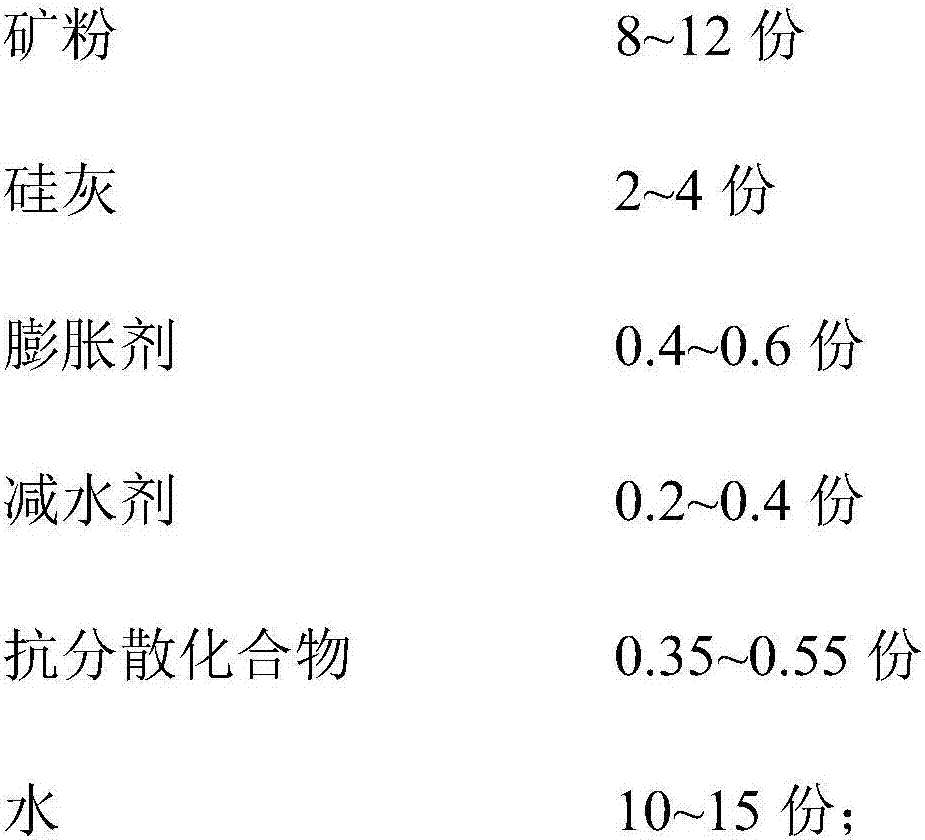

[0043] A cement-based grouting material, which is specifically composed of the following components:

[0044]

[0045] Wherein, the fine aggregate is river sand with a particle size of 1.5-2.2mm, and the specific surface area of the mineral powder is 2000m 2 / kg; the silica fume bulk density is 500kg / m 3 , the expansion agent is a mixture of alkali metal plastic expansion agent and calcium sulfoaluminate concrete expansion agent with a mass ratio of 1:50; the water reducing agent is a polycarboxylate high-performance water reducing agent; the anti-dispersion The compound is a mixture of polyacrylamide and hydroxypropyl guar gum with a mass ratio of 1:2.

[0046]In this embodiment, the cement-based grouting material is prepared by the following steps:

[0047] Mix the anti-dispersion compound with the water and stir for 2 minutes; add 12.3g of the ordinary Portland cement, 24.5g of the fine aggregate, 5g of the mineral powder, 1.5g of the silica fume and 0.17g of the Sa...

Embodiment 2

[0049] A cement-based grouting material mixed with the following components by weight:

[0050]

[0051] Wherein, the fine aggregate is river sand with a particle size of 0.5-1.2mm, and the mineral powder has a specific surface area of 1600m 2 / kg; the silica fume bulk density is: 300kg / m 3 , the expansion agent is a mixture of alkali metal plastic expansion agent and calcium sulfoaluminate concrete expansion agent with a mass ratio of 1:60, the water reducer is a polycarboxylate high-performance water reducer, and the anti-dispersion The compound is a mixture of polyacrylamide and hydroxypropyl guar gum with a mass ratio of 1:2.

[0052] In this embodiment, the cement-based grouting material is prepared by the following steps:

[0053] Mix the anti-dispersion compound with the water and stir for 1 min; add 11.67g of the ordinary Portland cement, 22.5g of the fine aggregate, 4g of the mineral powder, 1g of the silica fume and 0.13g of the Expanding agent, stirring for ...

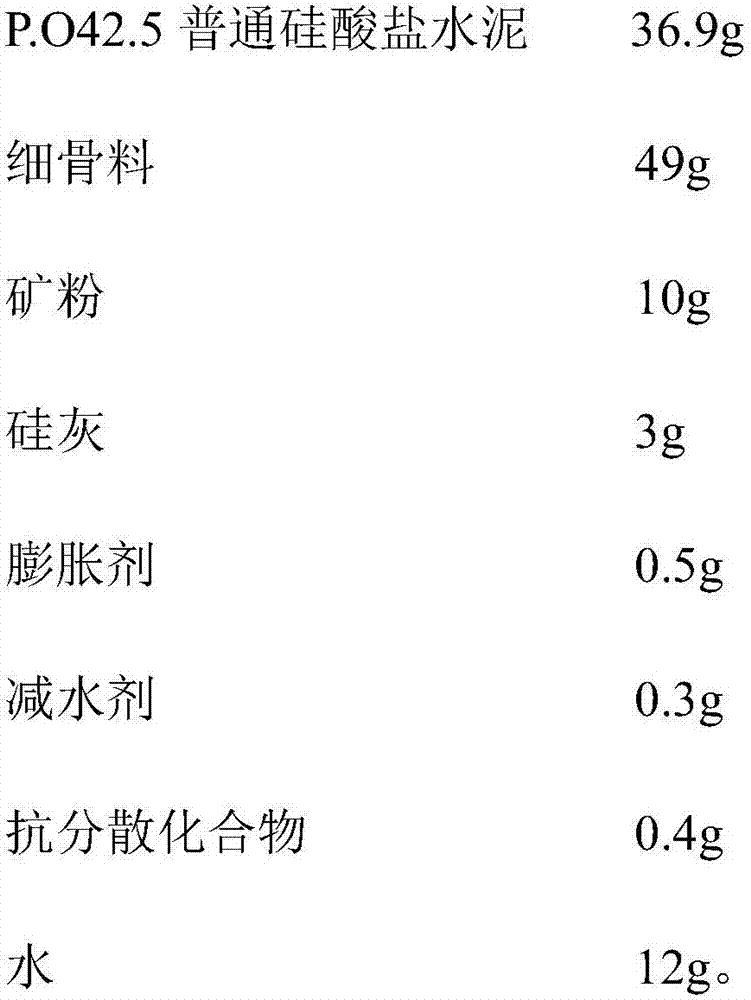

Embodiment 3

[0055] A cement-based grouting material mixed with the following components by weight:

[0056]

[0057] Wherein, the fine aggregate is river sand with a particle size of 0.6-1.5mm, and the specific surface area of the mineral powder is 1400m 2 / kg; the silica fume bulk density is 600kg / m 3 , the expansion agent is a mixture of alkali metal plastic expansion agent and calcium sulfoaluminate concrete expansion agent with a mass ratio of 1:70; the water reducer is a polycarboxylate high-performance water reducer, and the anti-dispersion The compound is a mixture of polyacrylamide and hydroxypropyl guar gum with a mass ratio of 1:2.

[0058] In this embodiment, the cement-based grouting material is prepared by the following steps:

[0059] Mix the anti-dispersion compound with the water and stir for 2 minutes; add 13.3g of the ordinary Portland cement, 27.5g of the fine aggregate, 6g of the mineral powder, 2g of the silica fume and 0.2g of the Expansion agent, stirred for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com