Automatic quality monitoring method based on metadata and terminal

A technology of quality monitoring and metadata, applied in data processing applications, data exchange networks, electrical components, etc., can solve problems such as manual input, low timeliness, manual screening and missed detection, etc., to improve efficiency, reduce manual input, The effect of wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

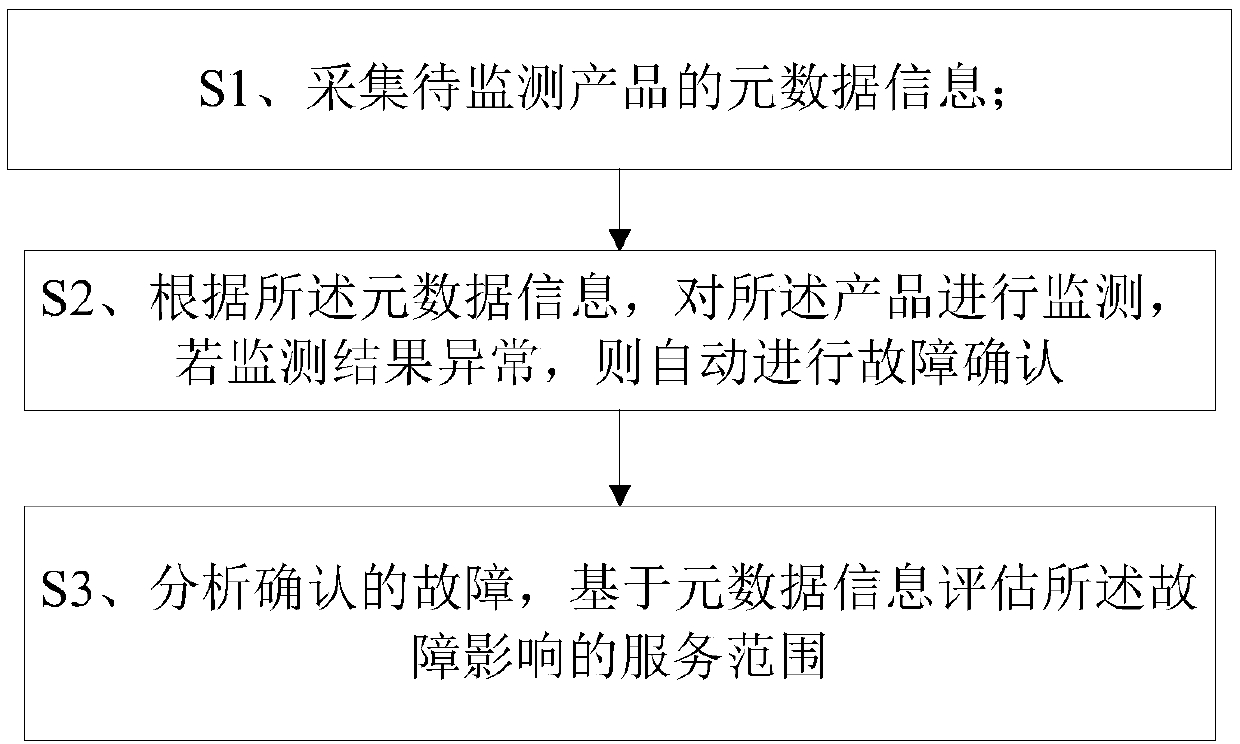

[0090] Please refer to figure 1 , an automatic quality monitoring method based on metadata, comprising the steps of:

[0091] S1. Collect metadata information of the product to be monitored;

[0092] Among them, specifically collect the metadata information of the product to be monitored, such as the fields, libraries, tables, and reference relationships used by the product, as well as the component list and operation log of other components referenced by the product to be monitored;

[0093] S2. Monitor the product according to the metadata information, and automatically confirm the fault if the monitoring result is abnormal;

[0094] Among them, different types of products have different monitoring methods;

[0095] For products assembled with non-reference components, that is, self-developed products, use server-side monitoring and log analysis to initiate regular monitoring of the product; server-side monitoring simulates user usage scenarios through automated dial-up te...

Embodiment 2

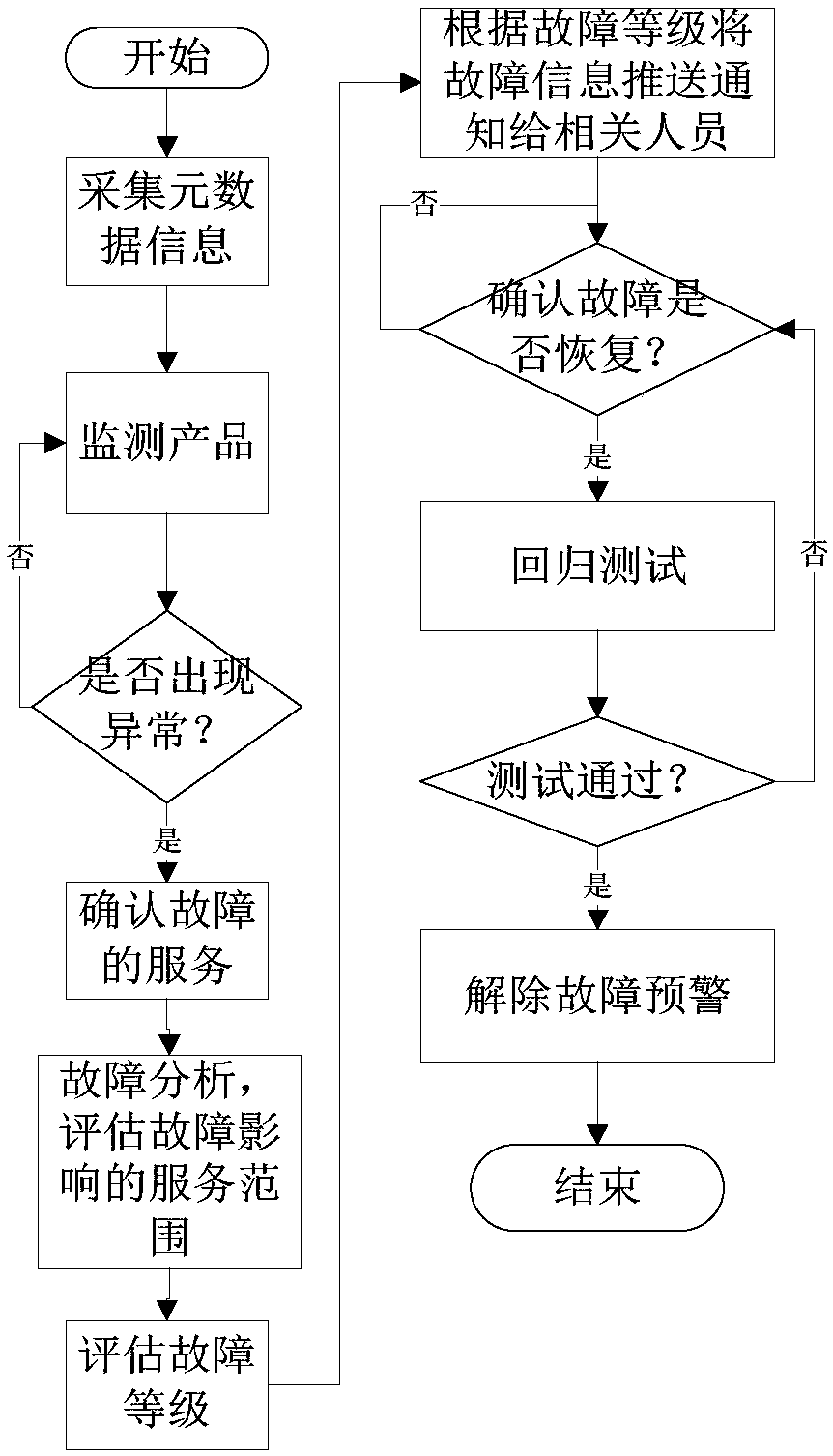

[0113] Please refer to image 3 , the difference between this embodiment and Embodiment 1 is that it also includes steps:

[0114] After evaluating the service scope affected by the failure, further evaluate the failure level, and confirm the failure level according to the service scope affected by the failure assessed above. Time processing; if the important function of the product under test is abnormal, but the scope of influence is a small number of users, or the non-important function is abnormal, the fault level is high; according to different fault levels, it will be synchronously pushed to relevant personnel in different functional areas for follow-up and processing to ensure multi-party information synchronization and collaborative processing;

[0115] S4. Regularly evaluate the monitoring results to confirm whether the fault has been recovered, and if it is detected that the fault has recovered, perform a regression test on the service scope affected by the fault; ...

Embodiment 3

[0128] Please refer to figure 2 , an automatic quality monitoring terminal 1 based on metadata, comprising a memory 2, a processor 3 and a computer program stored on the memory 2 and operable on the processor 3, the processor 3 executing the computer program Each step in the first embodiment is realized at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com