A fully automatic pasta machine

A technology of pasta machine and machine base, which is applied in the direction of dough mixer, food science, structural components of mixing/kneading machinery, etc. It can solve the problems of difficult cleaning of mixing rod, failure of noodle making, frequent overloading, etc., and save the total time of noodle making The effect of saving time, reducing the cost of raw materials, and improving the efficiency of noodle making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

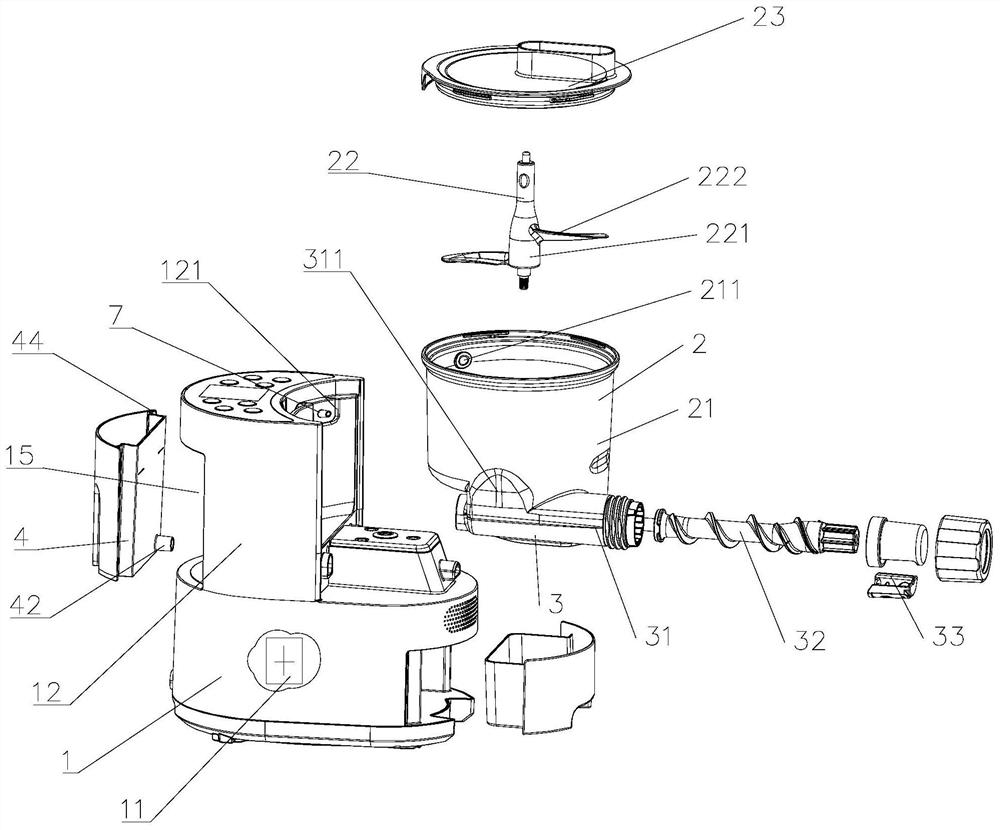

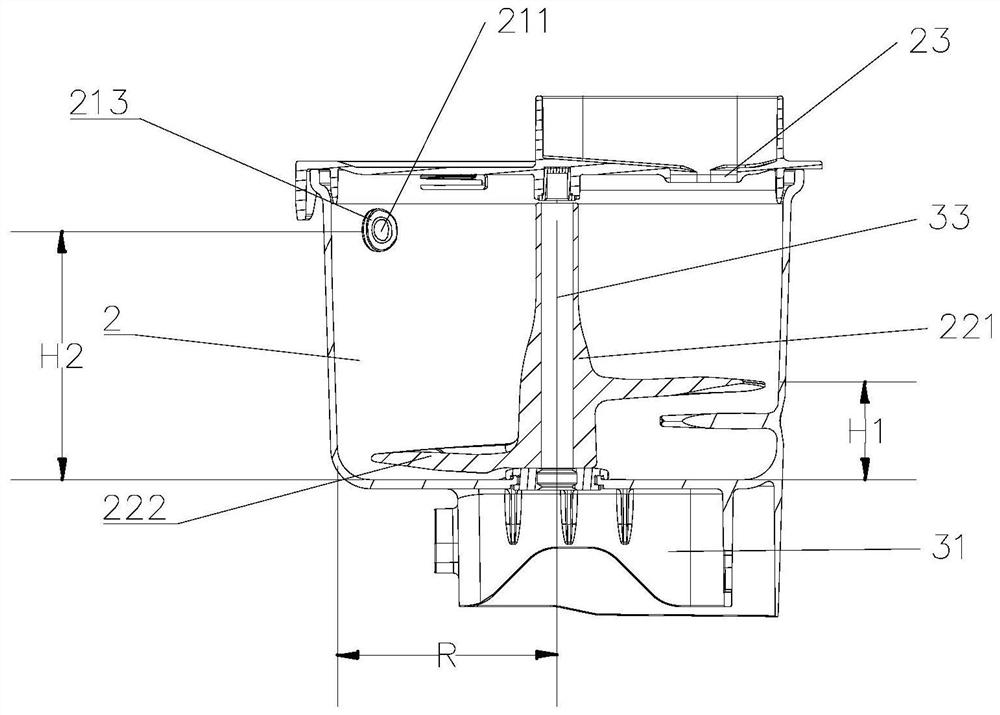

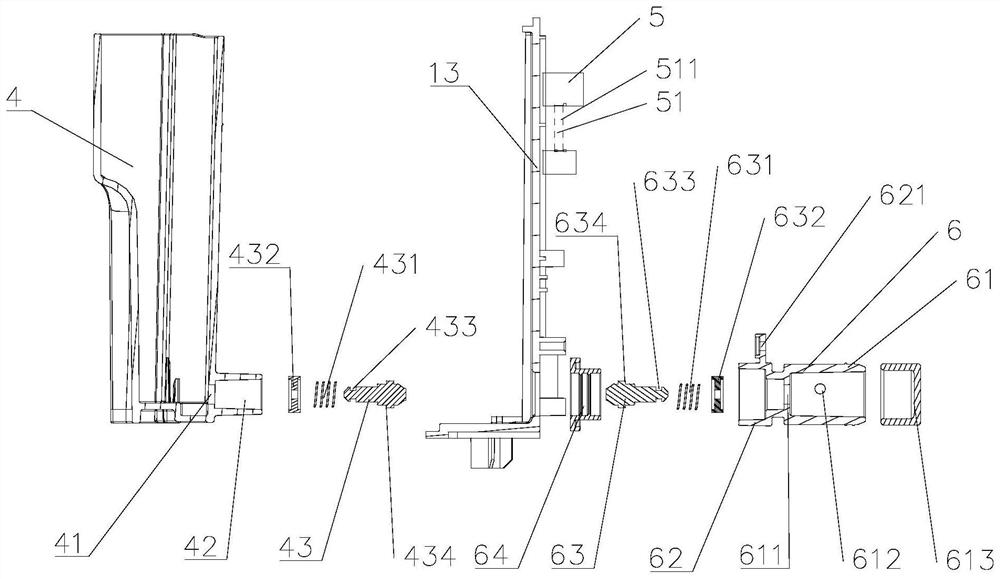

[0051] Such as Figure 1 to Figure 7 As shown, the present embodiment provides a fully automatic pasta machine, including a machine base 1, a motor 11 and a control unit are arranged in the machine base, a stirring assembly 2 and an extruding assembly 3 are arranged on the machine base, and the stirring assembly includes a stirring cup 21 , the stirrer 22 arranged in the stirring cup, and the upper cover 23 covering the upper port of the stirring cup, the extruding assembly includes a dough extruding cylinder 31 and a dough extruding screw 32, and the head end of the extruding cylinder is provided with a die assembly 33, The noodle extruding cylinder is provided with a noodle inlet 311 communicating with the mixing cup. In this embodiment, the noodle extruding cylinder 31 is arranged below the agitating cup. The agitating cup includes a side wall and a bottom wall, and the noodle inlet is arranged on the bottom wall. Above, the extruding cylinder is partly located under the mi...

Embodiment 2

[0081] Compared with Embodiment 1, this embodiment further optimizes the structure of the pasta machine.

[0082] Such as Figure 8 to Figure 10 As shown, the pasta machine also includes a weighing unit for weighing the weight of the material in the mixing cup. The weighing unit weighs the weight of the material in the mixing cup and feeds it back to the control unit. The control unit controls the weight of the material in the mixing cup. The automatic water inlet unit adds water to the mixing cup, so that the control unit determines the amount of water required according to the weight of the flour throughout the noodle making process. The ratio of flour to water is accurate and the error is small, and the success rate of noodle making is high. Specifically, such as Figure 8 As shown, there is also a water pipe 212 at the water inlet 211, and the water pipe is sleeved in the water inlet 211. The central axis of the water pipe 212 and the central axis of the agitator 22 are a...

Embodiment 3

[0098] The difference between this embodiment and the second embodiment is that the base structure is different.

[0099] Such as Figure 11 As shown, in this embodiment, a sunken platform 152 is provided at the joint between the bottom plate and the edge of the enclosure opening, and the water tank is horizontally installed in the installation cavity 15 and set against the sunken platform downwards. When the pasta machine is tilted, the water tank is not easy to Slide out from the installation cavity to ensure reliable installation and positioning of the water tank, reliable connection between the water outlet channel and the water guide seat, and not easy to disengage during use. The water inlet speed of the water inlet 211 is V2, 150mL / min≤V2≤300mL / min, V2 is 220mL / min, so as to shorten the time of the stirring stage and improve the efficiency of the stirring stage.

[0100] understandable, such as Figure 12 As shown, the structure of the installation cavity 15 and the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com