Press machine comprising drive controlled using recorded press data

A driver and controller technology, applied in the direction of presses, electrical digital data processing, digital data information retrieval, etc., can solve problems such as energy waste, damage to joints and pipes to be connected

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

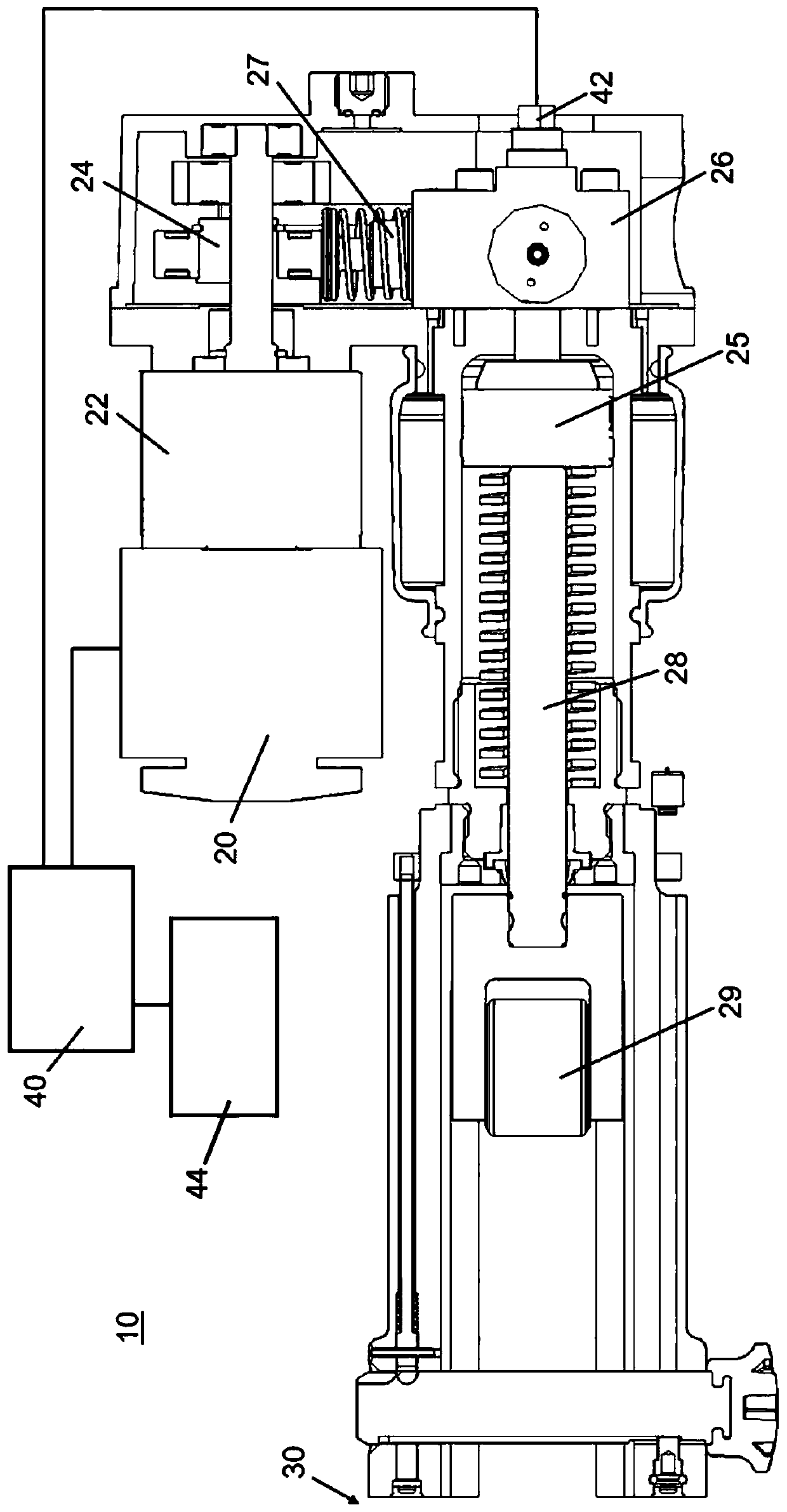

[0040] figure 1 An embodiment of a hydraulic hand-held extrusion device or press 10 with a hydraulic force transfer unit is shown. In the hydraulic handheld extrusion machine, a motor 20 drives an eccentric 24 connected thereto via a transmission 22 . Preferably, the motor 20 is a brushless motor powered by the controller 40 using a correspondingly modulated current from a battery or cable connected power supply (not shown). The transmission mechanism 22 reduces the rotational speed of the motor 20 and increases the torque. An eccentric device 24 connected to the transmission mechanism converts the rotational motion of the output shaft of the transmission mechanism 22 into a one-dimensional oscillatory motion to drive a piston pump 27 of a hydraulic system 26 . The piston pump 27 pumps hydraulic fluid from the reservoir into the working cylinder 25 based on its movement, thereby increasing the hydraulic pressure in the working cylinder 25 . The elevated hydraulic pressure d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com