Positioning method for low-bending-moment clamping of small clamping surface of complex bracket part

A positioning method and part technology, applied in positioning devices, metal processing machinery parts, clamping and other directions, can solve the problems of easy vibration, affect the machining accuracy and consistency, reduce the bending moment of the clamping, improve the qualified efficiency and consistency, improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will now be further described in conjunction with the embodiments and drawings:

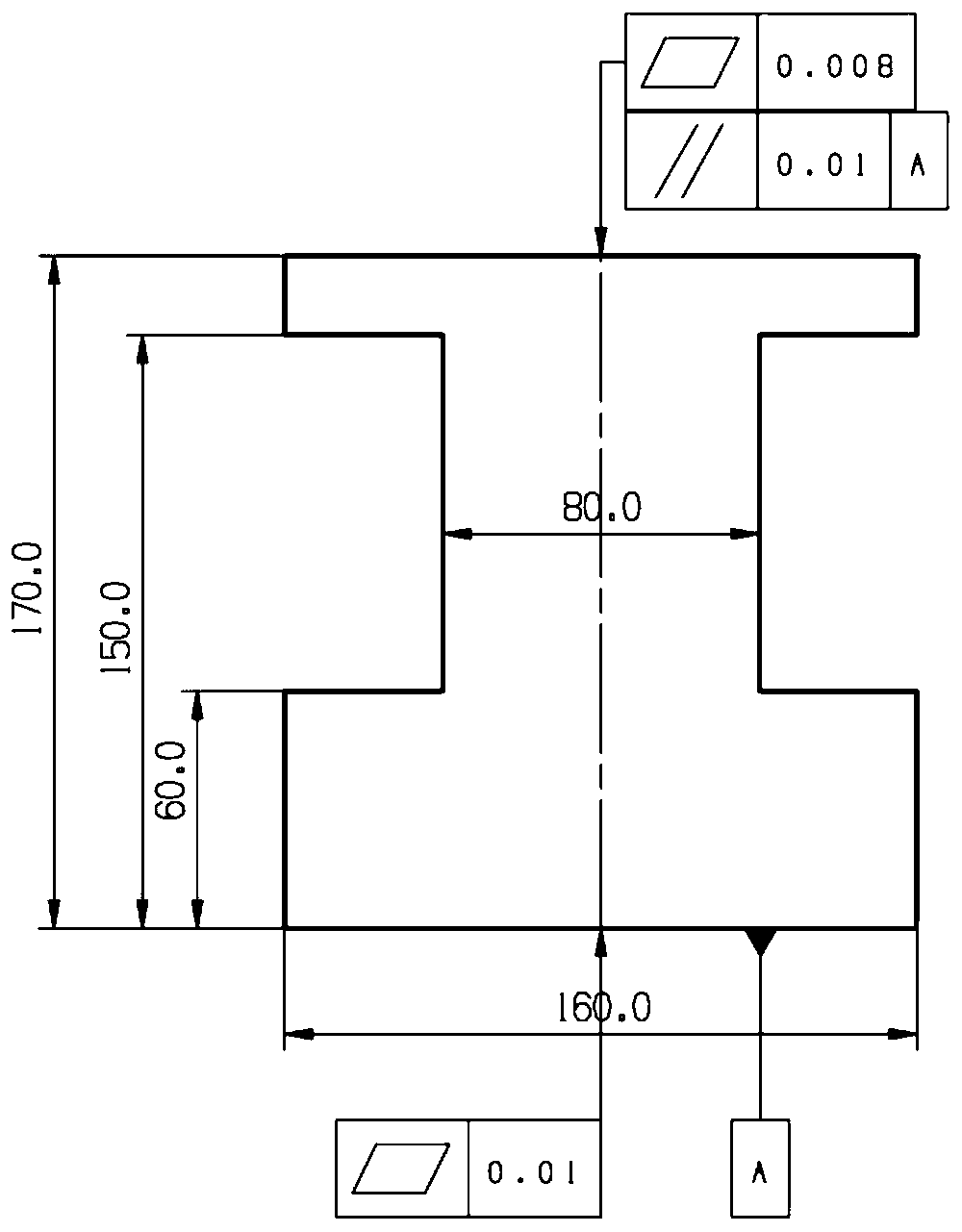

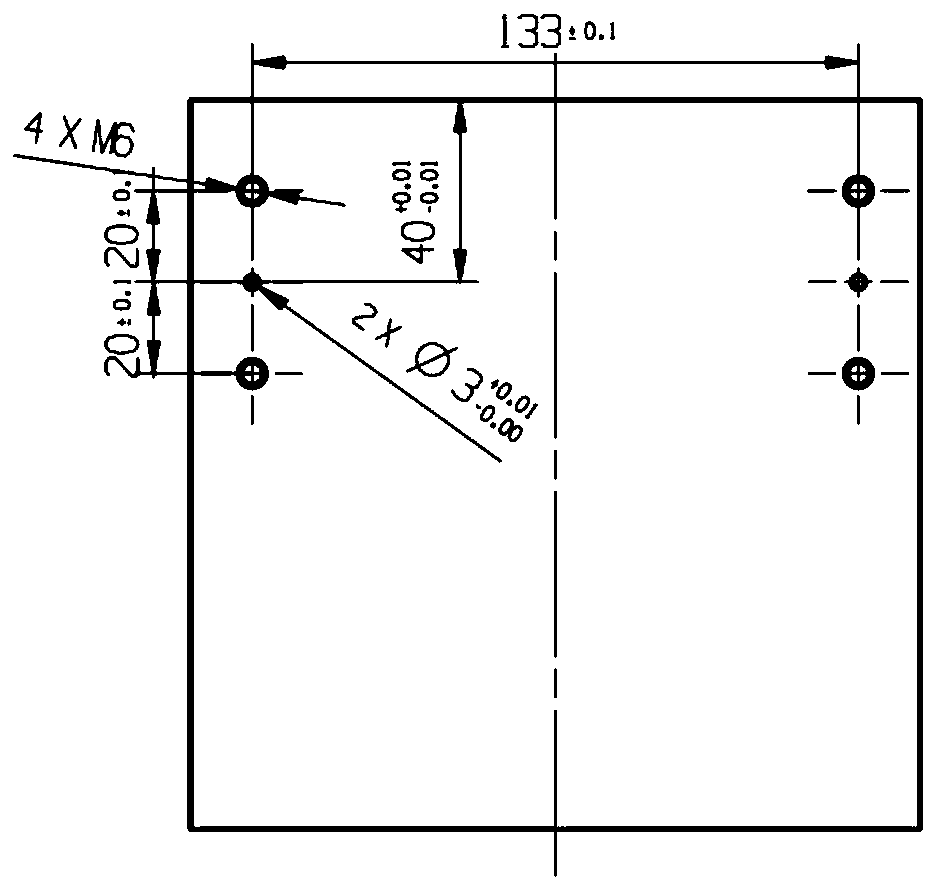

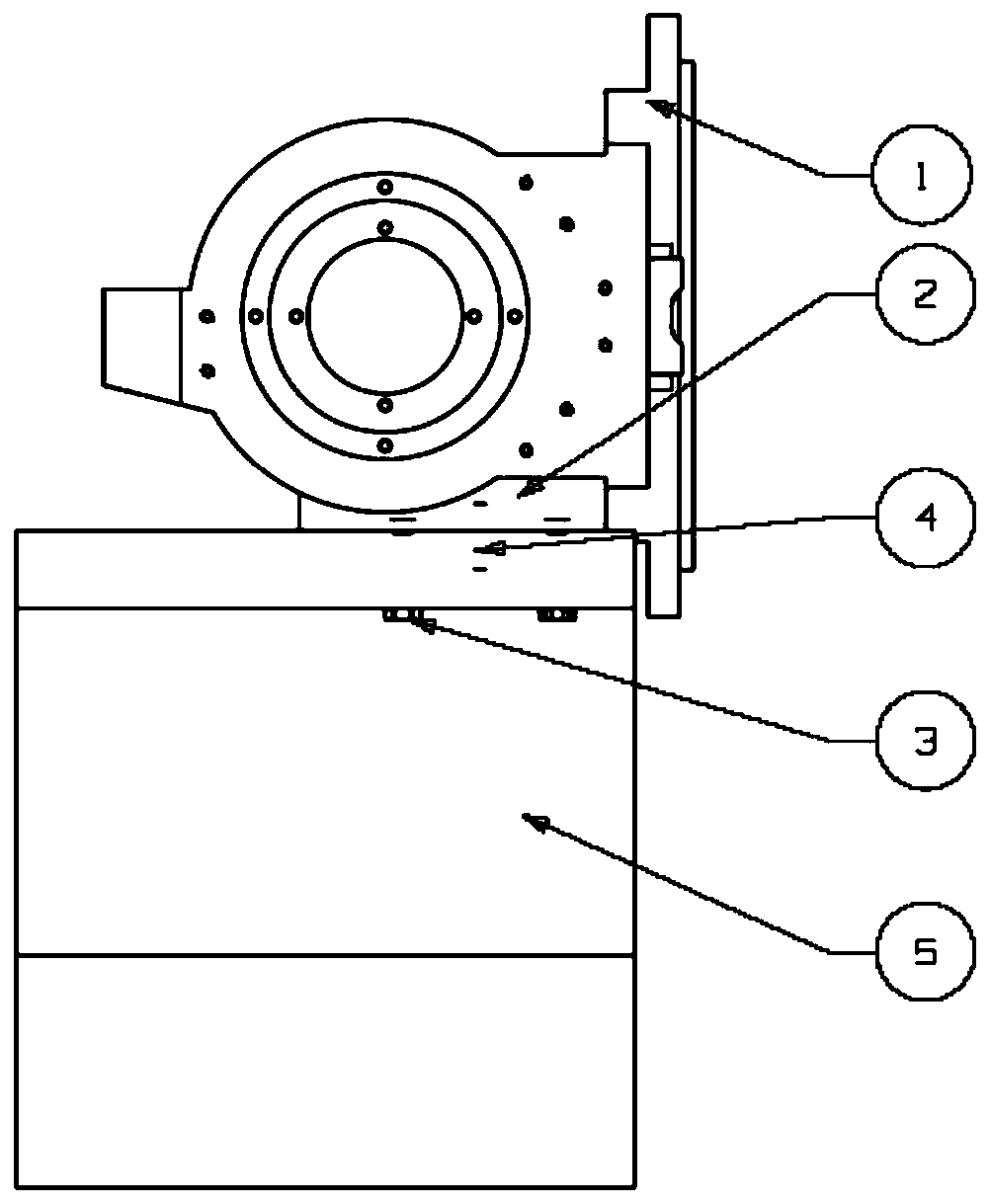

[0029] The invention adopts pin hole positioning and bolt reverse tension clamping to clamp small clamping surface bracket parts. The flatness of the tooling reference surface is required to be 0.01. The flatness requirement of the tooling mounting surface is 0.008; there are two sets of threaded holes 4×M6 on the tooling mounting surface, two positioning pin holes 2×Φ3, and the flatness requirement of the small clamping surface of the part process handle is 0.008. Correspondingly, there are two sets of threaded holes 4×M6 and two positioning pin holes 2×Φ3. After rough machining of bracket parts, the small clamping surface and tooling installation surface are processed to ensure the flatness requirements. Then drill the positioning pin holes. When clamping parts and fixtures, first install the positioning pins, and then match the parts with the fixtures through the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com