A polytetrafluoroethylene pipe coupling with internal leveling function

A teflon pipe and coupler technology, which is used in manufacturing tools, parts of grinding machine tools, machine tools suitable for grinding workpiece edges, etc. and other problems, to achieve the effect of small friction coefficient, smooth polished plane, and increased rotational speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

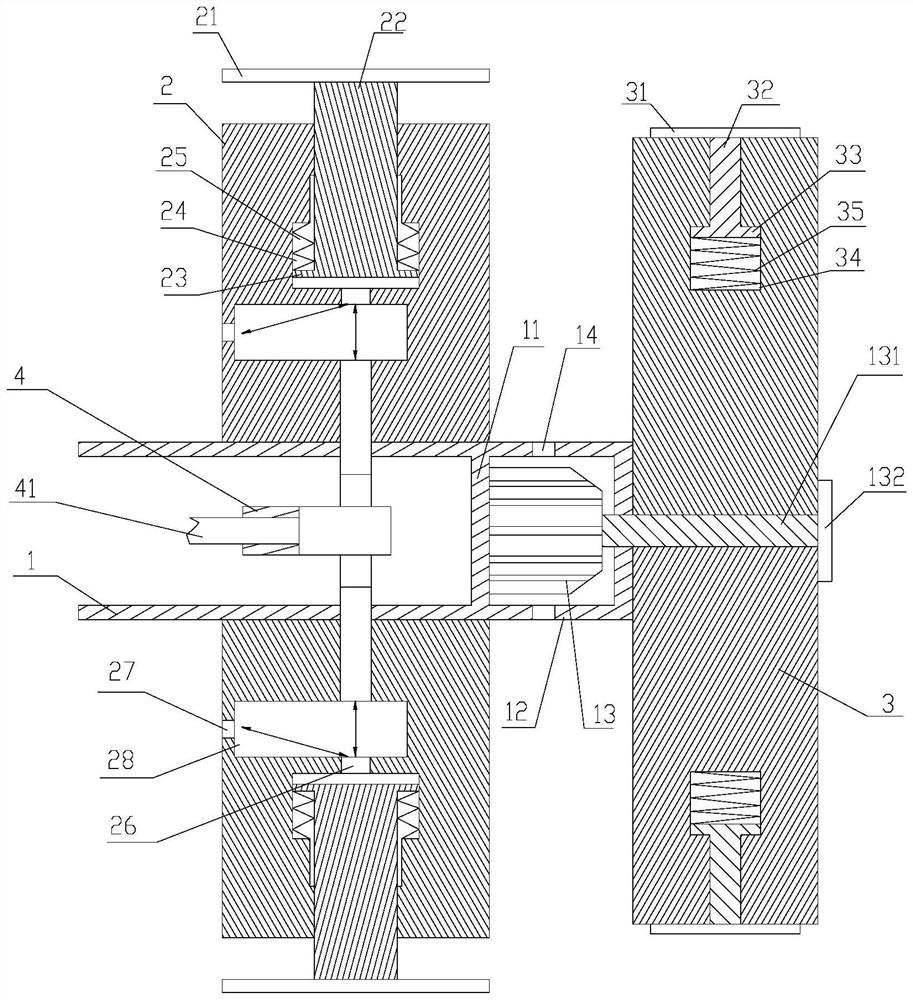

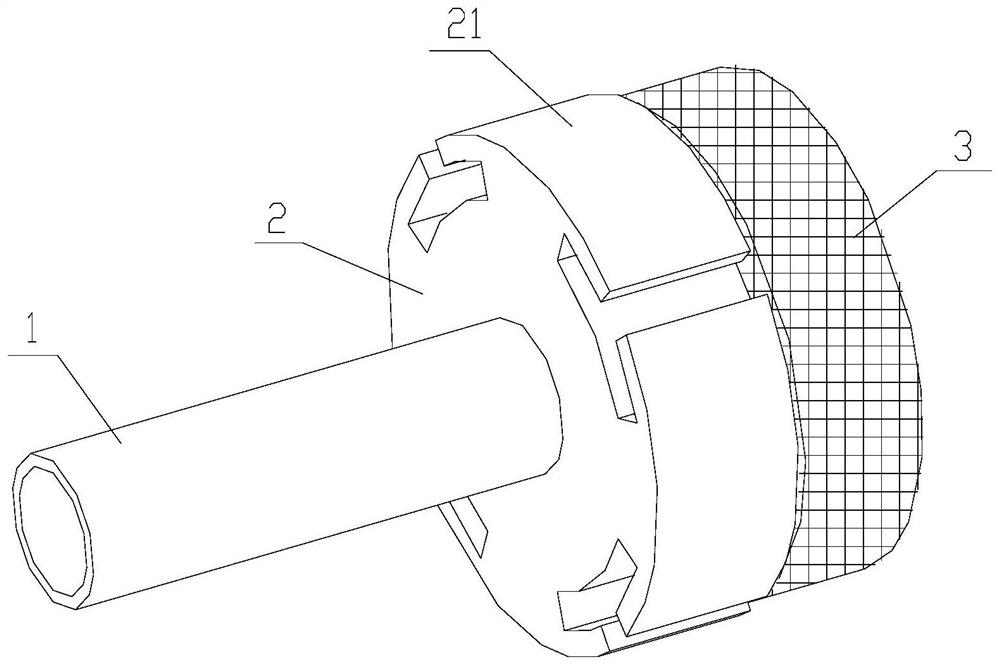

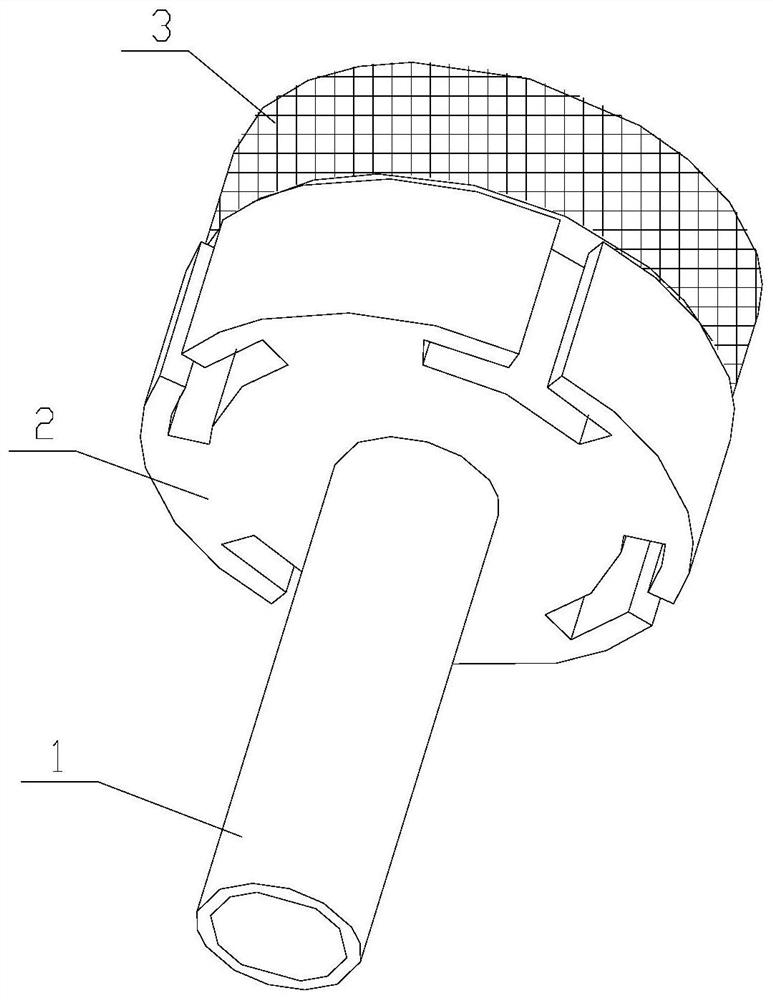

[0033] see Figure 1-Figure 5As shown, the embodiment of the present invention provides a PTFE pipe coupling with an inner leveling function, which includes a hand-held pipe 1, a first fastening device 2, a grinding device 3 and an air vent seat 4. The hand-held pipe 1, the first fastening device 2, the A fastening device 2 and a grinding device 3 are installed concentrically, the air vent seat 4 is installed inside the hand-held tube 1, the first fastening device 2 is fixedly installed on the hand-held tube 1, the grinding device 3 is installed on one end of the hand-held tube 1, and the first fastening device 2 is fixedly installed on the hand-held tube 1. A fastening device 2 communicates with the inside of the hand-held tube 1 through the first air inlet 26 , and the plurality of first air inlets 26 are installed on the air-passing seat 4 , and the hand-held tube 1 inside the first fastening device 2 is provided with a The web 11, the end positions of the web 11 and the ha...

Embodiment 2

[0042] The difference between Example 2 and Example 1 is that in Example 2, two fastening devices are used to fix the connecting polytetrafluoroethylene pipe and the connected polytetrafluoroethylene pipe concentrically.

[0043] see Image 6 , Figure 7 and Figure 8 As shown, the embodiment of the present invention provides a PTFE pipe coupling with an inner leveling function, which includes a hand-held pipe 1, a first fastening device 2, a grinding device 3 and an air vent seat 4. The hand-held pipe 1, the first fastening device 2, the A fastening device 2 and a grinding device 3 are installed concentrically, the air vent seat 4 is installed inside the hand-held tube 1, the first fastening device 2 is fixedly installed on the hand-held tube 1, the grinding device 3 is installed on one end of the hand-held tube 1, and the first fastening device 2 is fixedly installed on the hand-held tube 1. A fastening device 2 communicates with the inside of the hand-held tube 1 through ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap