Method for preparing low-temperature heating non-combustible cigarette paper by utilizing reconstituted tobacco and application thereof

A technology for heat-not-burn and reconstituted tobacco leaves, which is applied in the fields of tobacco preparation, application, and tobacco, and can solve the problems of chemical smell, high dosage, and influence on the sensory quality of cigarettes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

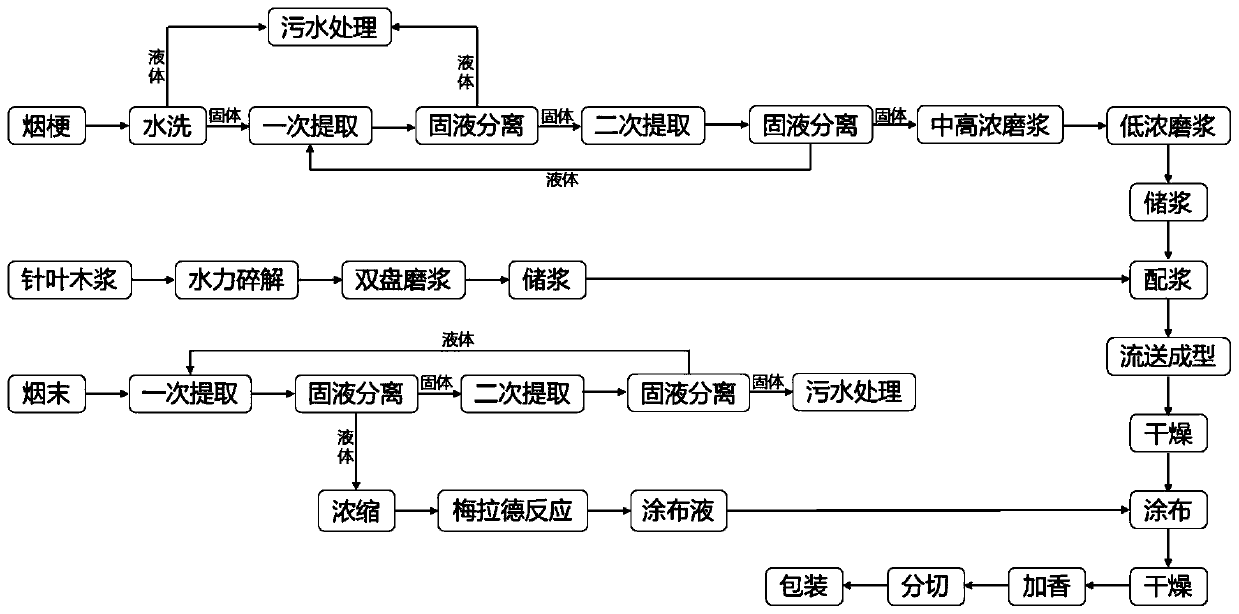

[0096] refer to figure 1 , a method for preparing low-temperature heat-not-burn cigarette paper by utilizing reconstituted tobacco leaves, comprising the steps of:

[0097] (1) Tobacco stems are often washed with warm water for 10 minutes and then extracted with clean water. The extraction temperature is 80°C, the extraction time is 20 minutes, the extraction solid-liquid ratio is 1:6, and the solid-liquid separation is carried out after extraction. The liquid is discarded. Afterwards, the tobacco stem fiber is subjected to secondary extraction, the extraction temperature is 80°C, the extraction time is 20 minutes, the extraction solid-liquid ratio is 1:6, the solid-liquid separation is carried out after extraction, the liquid is used for the first extraction of tobacco stem, and the tobacco stem fiber enters the pulping process .

[0098] (2) The tobacco stem fiber in step (1) is through two-stage medium-high concentration refining, beating degree 16 ° SR, wet weight 8g, refin...

Embodiment 2

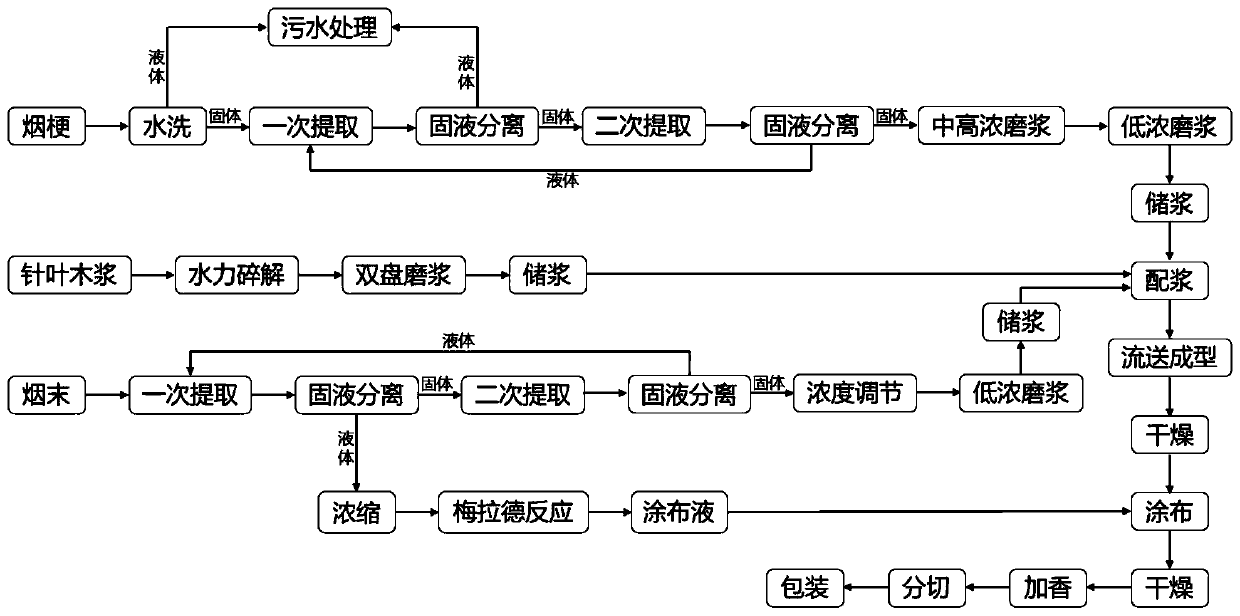

[0106] refer to figure 2 , a method for preparing low-temperature heat-not-burn cigarette paper using reconstituted tobacco leaves, comprising the steps of:

[0107] (1) Tobacco stems are often washed with warm water for 1 minute before extraction. The extraction temperature is 70°C, the extraction time is 50 minutes, the extraction solid-liquid ratio is 1:8, and the solid-liquid separation is carried out after extraction. The liquid is discarded. The stem fiber is extracted twice, the extraction temperature is 70°C, the extraction time is 350min, the extraction solid-liquid ratio is 1:8, the solid-liquid separation is carried out after extraction, the liquid is used for the first extraction of tobacco stem, and the tobacco stem fiber enters the pulping process.

[0108] (2) The tobacco stem fiber in step (1) is through two-stage medium-high concentration refining, beating degree 12 ° SR, wet weight 5g, refining concentration 22%, store in the stock tank, adjust the slurry co...

Embodiment 3

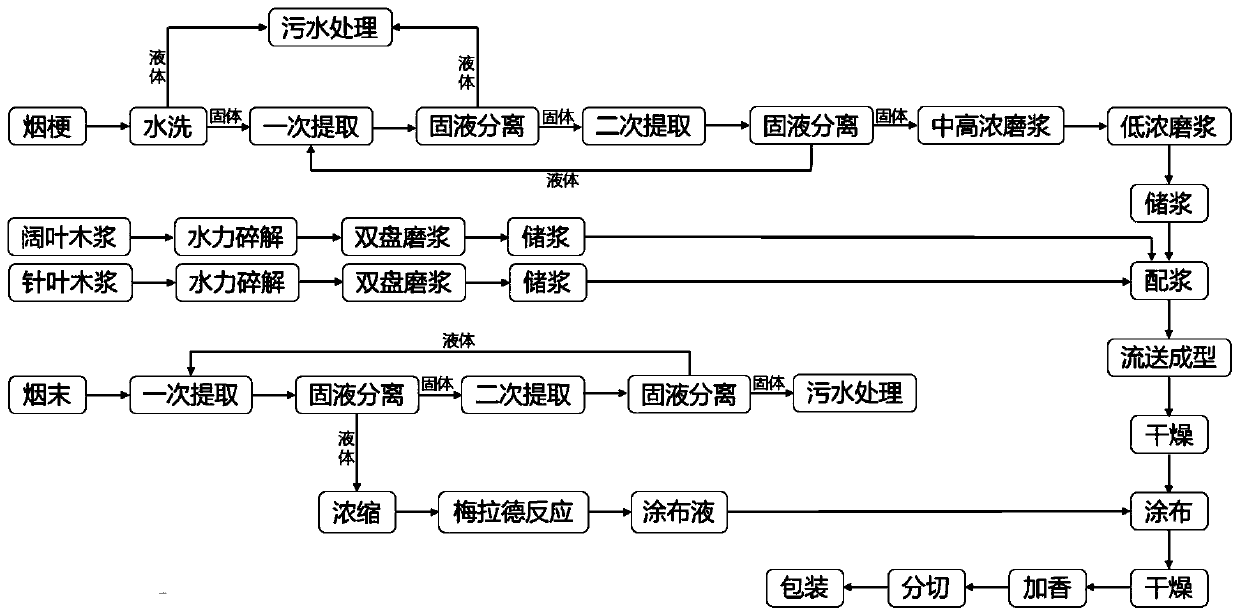

[0117] refer to image 3 , a method for preparing low-temperature heat-not-burn cigarette paper using reconstituted tobacco leaves, comprising the steps of:

[0118] (1) Tobacco stems are often washed with warm water for 8 minutes before extraction. The extraction temperature is 70°C, the extraction time is 60 minutes, the extraction solid-liquid ratio is 1:12, and the solid-liquid separation is carried out after extraction. The liquid is discarded. Stem fibers are subjected to secondary extraction, extraction temperature is 50°C, extraction time is 60 minutes, extraction solid-liquid ratio is 1:12, solid-liquid separation is carried out after extraction, the liquid is used for the first extraction of tobacco stems, and tobacco stem fibers enter the pulping process.

[0119] (2) Tobacco stems are refined through two stages of medium and high consistency, with a beating degree of 10°SR, a wet weight of 10g, and a refining concentration of 18%. The beating degree is 38°SR, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com