Processing technology of titanium alloy mobile phone frame

A mobile phone frame and processing technology, which is applied in metal processing equipment, driving devices for metal rolling mills, manufacturing tools, etc., can solve the problems of difficult processing and forming of titanium alloys, and achieve good material-to-weight ratio and good shape tolerance. , the effect of saving working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

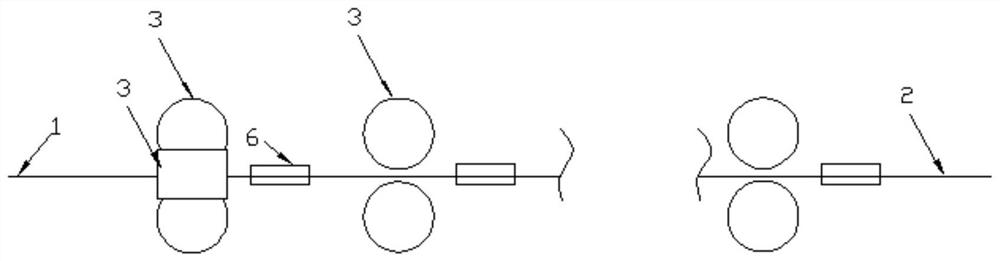

[0024] like Figure 1 to Figure 5 As shown, the present invention is a processing technology of a titanium alloy mobile phone frame, comprising rolling and heat-treating a titanium alloy bar 1 in a continuous cycle twelve times to form a strip-shaped mobile phone frame semi-finished profile 2; the rolling process adopts at least A pair of rolls 3 roll the titanium alloy bar 1, and the curved surface of the roll 3 used for rolling is provided with an annular protrusion 4 and / or an annular depression 5, and the annular protrusion 4 and the annular depression 5 are arranged concentrically with the corresponding roll 3 , the annular protrusion 4 and the annular depression 5 are similar to the shape of the profile after each rolling; the heat treatment adopts a tube furnace 6, the heat treatment temperature is 600±20°C, the length of the tube furnace 6 is 6 meters, and the titanium alloy rod The speed at which the material 1 passes through the tube furnace 6 is 3 m / min. The titani...

Embodiment 2

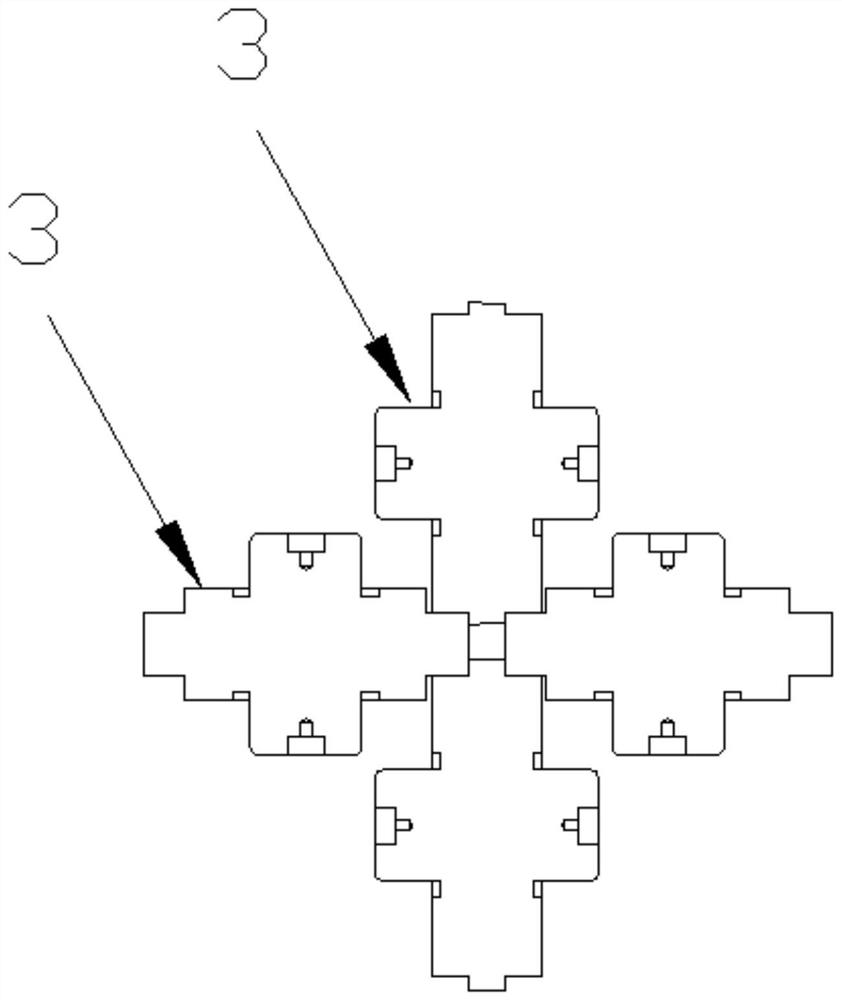

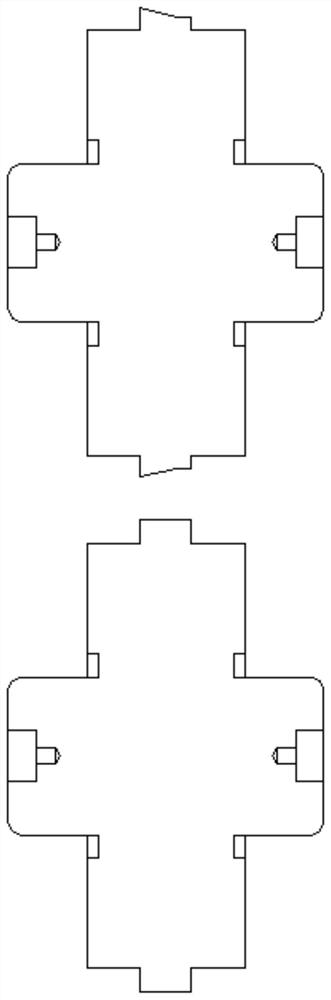

[0026] The difference from Embodiment 1 is that, as Figure 6 to Figure 8 As shown, when the titanium alloy bar 1 is rolled, the back plate 7 of the mobile phone shell is continuously cold-rolled on-line, and the roll for the mobile phone shell back plate 7 is continuously cold-rolled on-line and is used for rolling the titanium alloy bar 1. The rolls 3 are connected, and there are 10 pairs of rolls for the online continuous cold rolling of the mobile phone shell back plate 7, and each pair of rolls for the online continuous cold rolling of the mobile phone shell back plate 7 is formed in pairs by the first roll 8 and the second roll 9, The first roll 8 is provided with several bumps 10 on its curved surface for rolling, and the adjacent bumps 10 are provided with spacing, and the curved surface of the second roll 9 is used for rolling. Aligned depression; along the feed direction, the height of the bumps 10 of the first roller 8 on the subsequent process is higher than the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com