Machining technology of novel special-shaped material special for titanium alloy mobile phone SIM card tray

A processing technology, titanium alloy technology, applied in the direction of metal rolling, furnace type, manufacturing tools, etc., can solve the problems of difficult processing, high specific strength and difficult forming of titanium alloys, so as to reduce the amount of waste, high strength and reduce waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

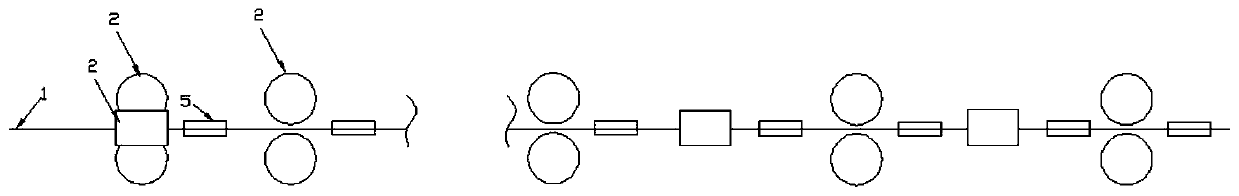

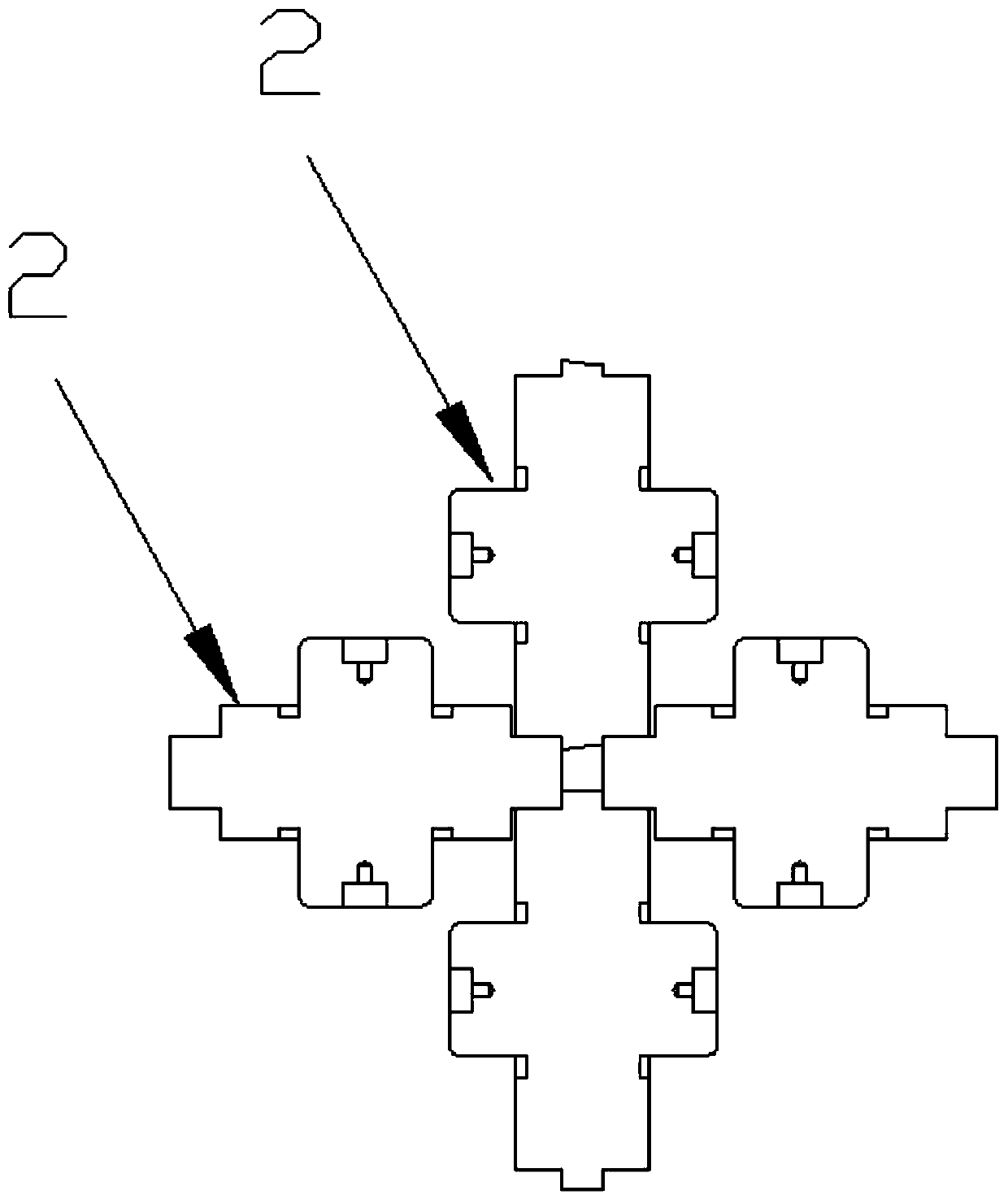

[0020] Such as Figure 1 to Figure 4 As shown, the present invention is a kind of processing technology of the special-shaped special-shaped material of a kind of titanium alloy mobile phone SIM card holder, comprises carrying out the rolling of titanium alloy bar 1 continuous cycle twelve times, heat treatment is made into the profiling profile of mobile phone SIM card holder , the rolling process uses at least one pair of rolls 2 (one pair or two pairs or one pair plus one mode) to roll the titanium alloy bar 1, and the two rolls 2 of the pair of rolls 2 are respectively provided with annular protrusions 3 and The ring-shaped depression 4, the ring-shaped protrusion 3 and the ring-shaped depression 4 are adapted to be arranged, the ring-shaped protrusion 3 and the ring-shaped depression 4 are arranged concentrically with the roll 2, and the ring-shaped protrusion and the ring-shaped depression are adapted to the shape of the profile after each rolling; The tube furnace 5 is ...

Embodiment 2

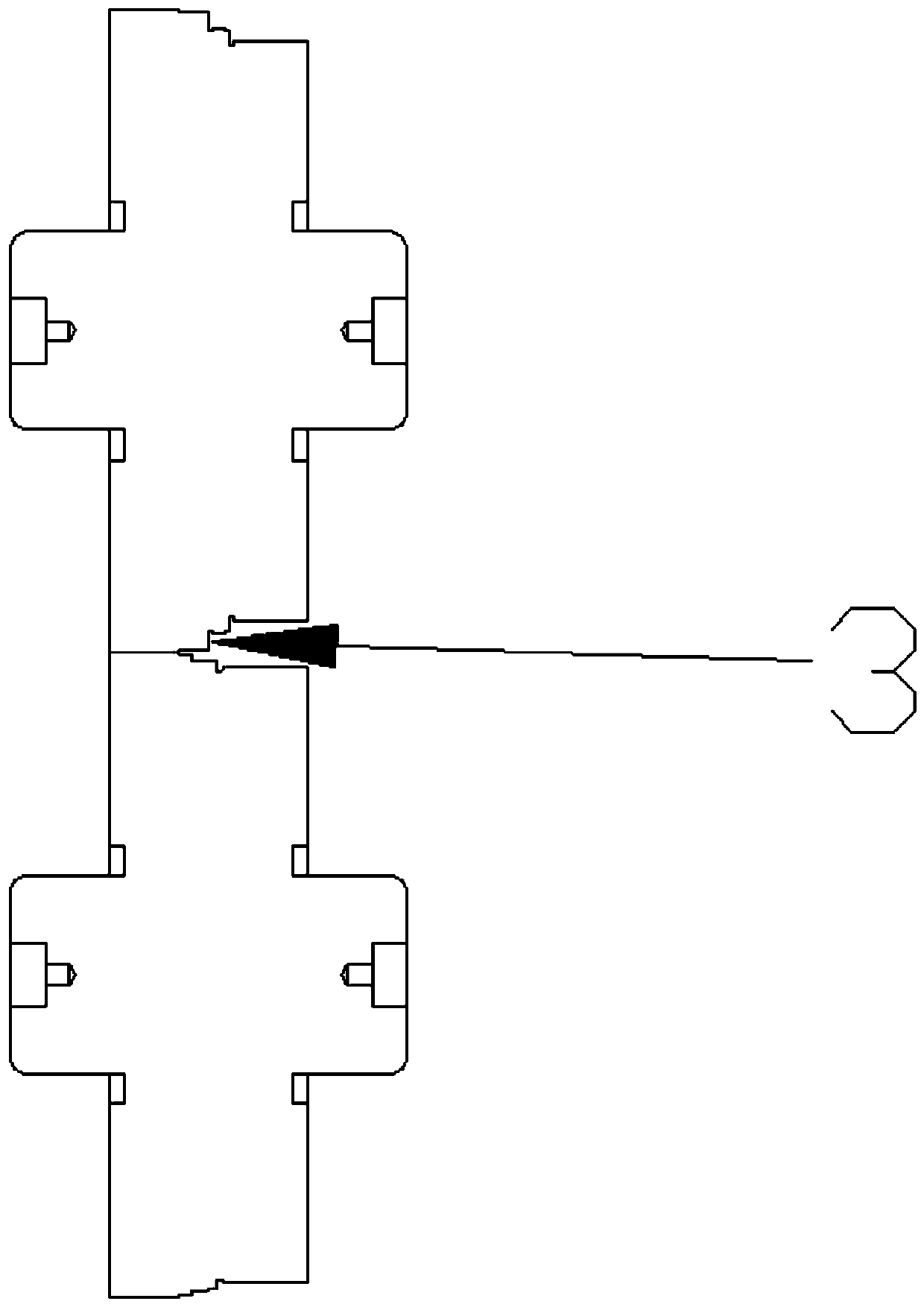

[0022] The difference from Embodiment 1 is that, as Figure 5 , Figure 6 As shown, in the process of rolling and heat treating the titanium alloy rods in a continuous cycle twelve times, the rivet holes 8 on the card body 7 of the card tray 6 are processed into blind holes through continuous rolling and then subsequently re-rolled. The rivet holes 8 are processed by CNC engraving. In the rolling and heat treatment process of twelve continuous cycles of titanium alloy rods, there are also three to four continuous cycle rolling and heat treatment processes for rolling and heat treatment of the inner wall of the card holder 6 and its card body 7 ( figure 1 The far right in the middle shows two steps of rolling and heat-treating the inner wall of its card body 7 of the card holder 6) in order to roll out the inner wall of its card body 7 of the card holder 6 for bearing the slot 9 for placing the SIM card.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com