Novel automatic and accurate PCB splitting equipment

A PCB board and board separation technology, which is applied in the field of new automatic and precise PCB board separation equipment, can solve the problems of affecting product quality, low operation efficiency, and violence of workers' board separation methods, so as to reduce labor intensity and production cost, and realize separation The effect of board automation and standardization of sub-board operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

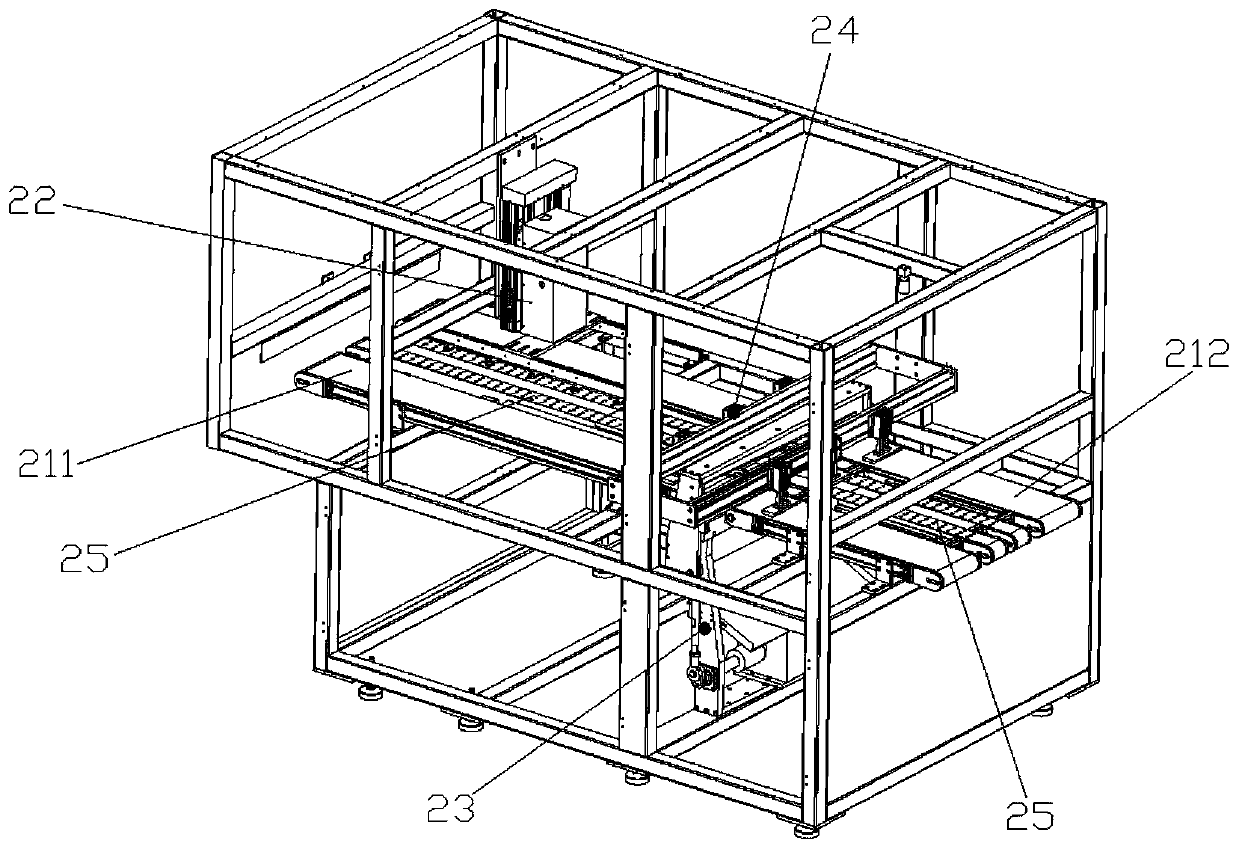

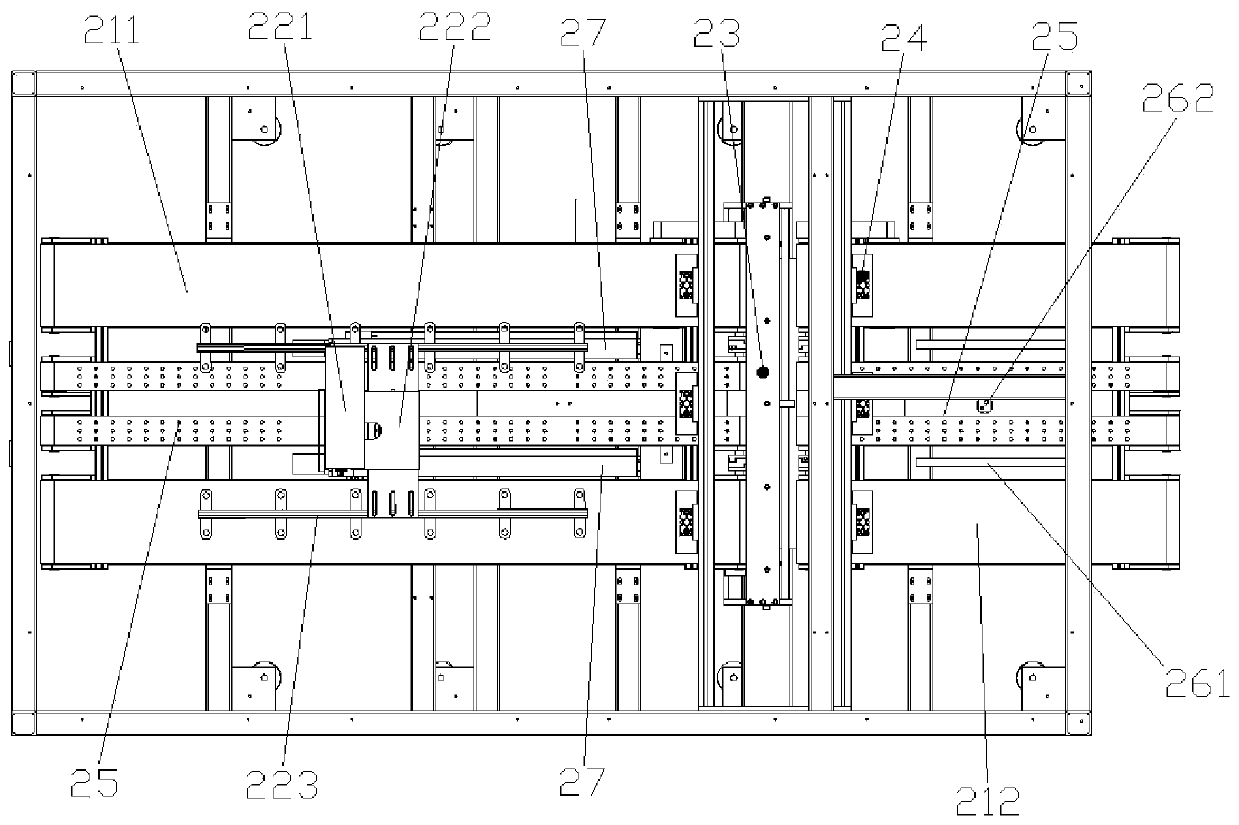

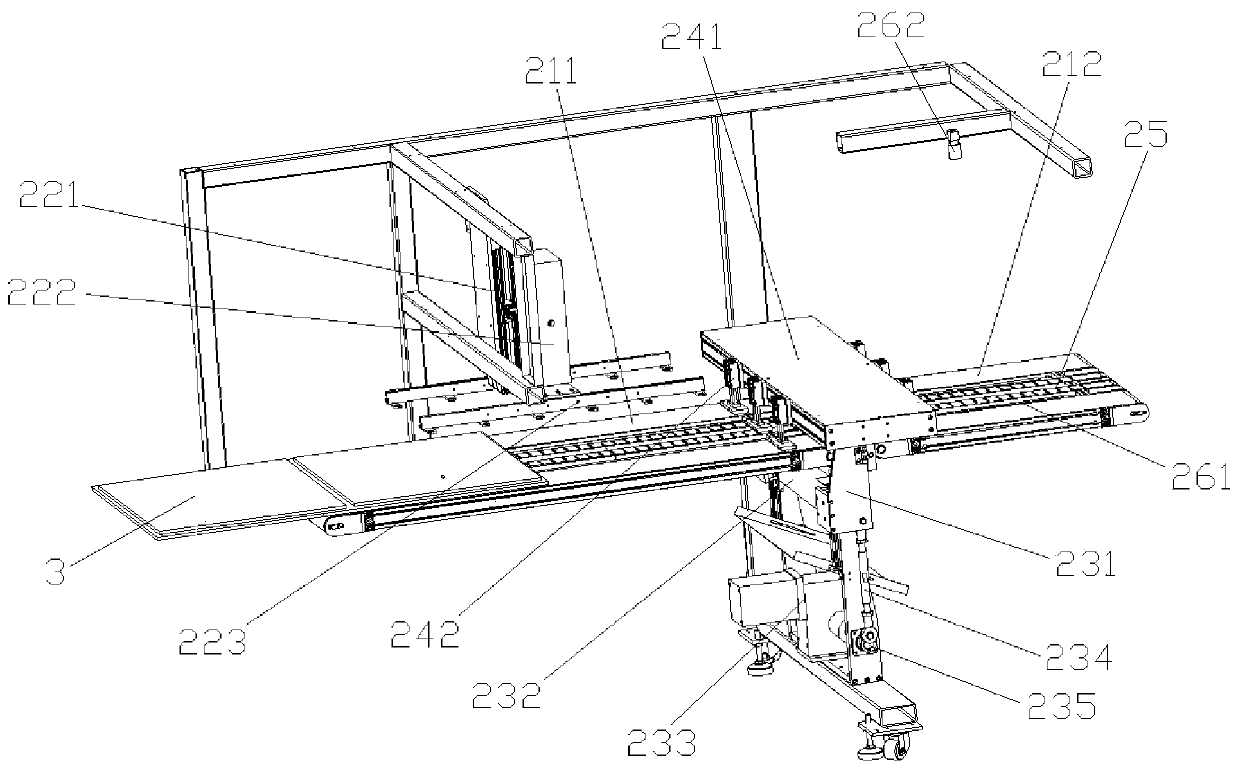

[0024] Such as Figure 1~4 , the present embodiment provides a new type of PCB board automatic and precise splitting equipment, including a strip conveyor belt for conveying PCBs, a position feedback system for feeding back PCB position information, an angle adjustment manipulator for adjusting the angle of the PCB, and a The guillotine splitting assembly 23 for dividing the PCB into two, the pressing plate assembly 24 for pressing the top surface of the PCB, and the vacuum adsorption assembly 25 for adsorbing the bottom surface of the PCB.

[0025] The split type conveyor belt includes an input conveyor belt 211 and an output conveyor belt 212, the angle adjustment manipulator is located above the input conveyor belt 211, and the guillotine splitting assembly 23 is located between the input conveyor belt 211 and the output conveyor belt 212,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com