Equipment for tearing adhesives on two sides of packaging film

A packaging film and sticker technology, applied in the field of packaging equipment, can solve the problems of affecting the quality and effect of packaging, consuming a lot of manpower, and low production efficiency, and achieving the effects of improving packaging consistency, reducing labor intensity and increasing output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

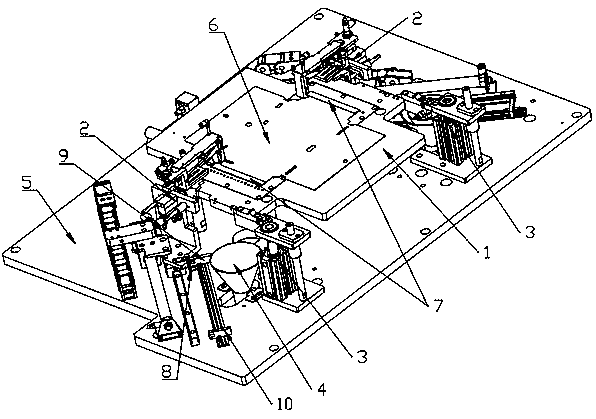

[0026] Such as figure 1 As shown, the equipment for tearing the stickers on both sides of the packaging film includes an adsorption platform 1 , a gripper peeling sticker mechanism 2 , an auxiliary collection mechanism 3 , a collection hopper 4 , and a main mounting plate 5 .

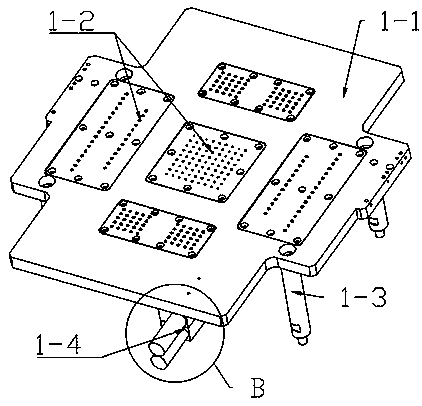

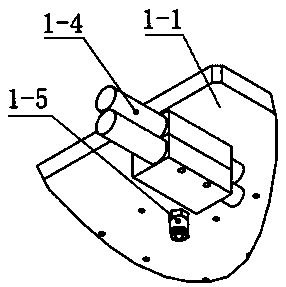

[0027] Adsorption platform 1 is installed on the main mounting plate 5, such as figure 2 , 3 As shown, the adsorption platform 1 includes a support plate 1-1, a suction hole plate 1-2, a pillar 1-3, a vacuum generator 1-4, and a gas pipe joint 1-5. The support plate 1-1 passes through The pillar 1-3 is installed on the main mounting plate 5, the support plate 1-1 is provided with at least two suction hole plates 1-2, the vacuum generator 1-4 is installed on the bottom of the support plate 1-1, each suction hole The adsorption cavity of the plate 1-2 is connected with the vacuum generator 1-4 through the gas pipe joint 1-5. By adopting the vacuum generator 1-4 to make the hole surface of the suction ...

Embodiment 2

[0033] On the basis of Embodiment 1, an induction rod 8 is fixedly installed on the support base 2-3, a front sensor 9 and a rear sensor 10 are installed on the main mounting plate 5, and the induction rod 8 is located between the front sensor 9 and the rear sensor 10. Between the rear sensors 10, the front sensor 9 and the rear sensor 10 are respectively connected to the PLC 11. The position sensor is connected with PLC11 respectively, and PLC11 is connected with traverse cylinder 2-1, jaw down cylinder 2-5, jaw compression cylinder 2-6, and air blowing valve and air nozzle 3-6 on air pipe 2-11 The blowing valve on the connection, the circuit control such as Figure 9 shown.

[0034] The traversing cylinder 2-1 is activated, and the traversing cylinder 2-1 drives the fixed jaw 2-9 and the movable jaw 2-7 to move above one end of the sticker 7. When the sensing rod 8 touches the front sensor 9, The front sensor 9 transmits the signal to the PLC11, and the PLC11 controls the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com