Method for detecting generalized orientation degree of polyacrylonitrile fibers by applying two-dimensional X-ray diffraction

A technology of polyacrylonitrile fiber and degree of orientation, which is applied in the direction of material analysis using radiation diffraction, and can solve problems such as inaccuracy and incompleteness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of the present invention will be further explained and described in the manner of specific embodiments below.

[0016] 1) The polyacrylonitrile fiber is tested by a two-dimensional X-ray diffractometer to obtain a two-dimensional diffraction pattern, and at the same time, the I(2θ,κ) curve can be obtained, that is, the diffraction intensity-diffraction angle-azimuth curve;

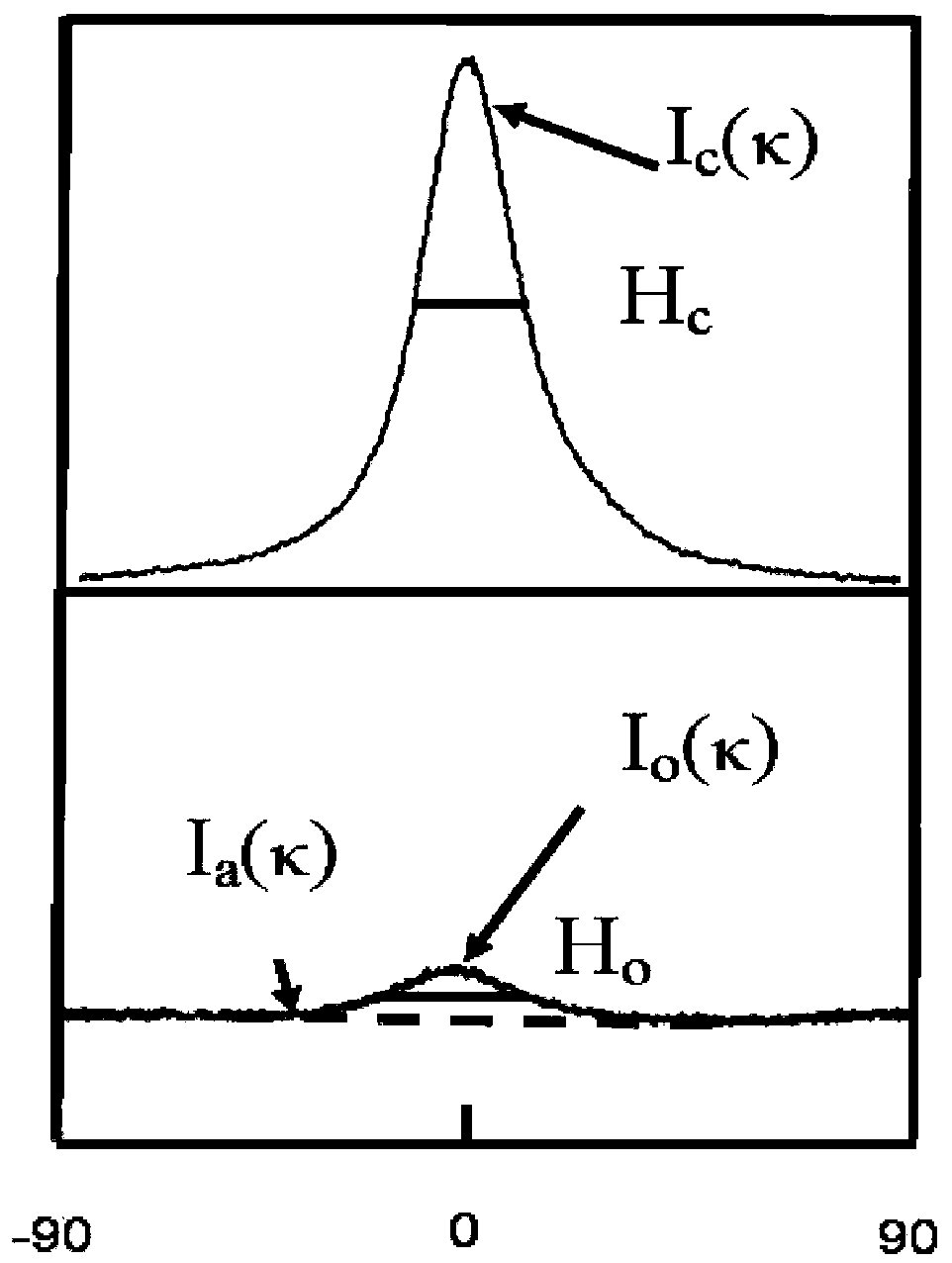

[0017] 2) For the crystal phase, select the (100) crystal plane diffraction angle 2θ c = 16.9°, at diffraction angle 2θ c Calculate the curve integral within the range of ±Δ2θ; for the oriented amorphous phase, select the diffraction angle 2θ o =25.2°, at diffraction angle 2θ o Calculate the curve integral within the range of ±Δ2θ; obtain the I~κ curve respectively, that is, the diffraction intensity-azimuth angle curve; Δ2θ is 1°~5°;

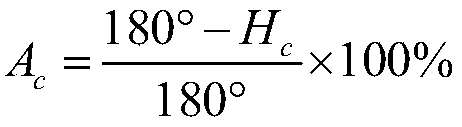

[0018] 3) Calculate the half-height width of the two I~κ curves respectively, and the half-height width of the crystalline phase curve is H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com