Characterization method and system for threshing and redrying tobacco sheet shapes

A technology for red-cured tobacco and tobacco sheets, which is applied in image data processing, instruments, calculations, etc., can solve problems such as inaccurate representation of threshed and red-cured tobacco sheets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

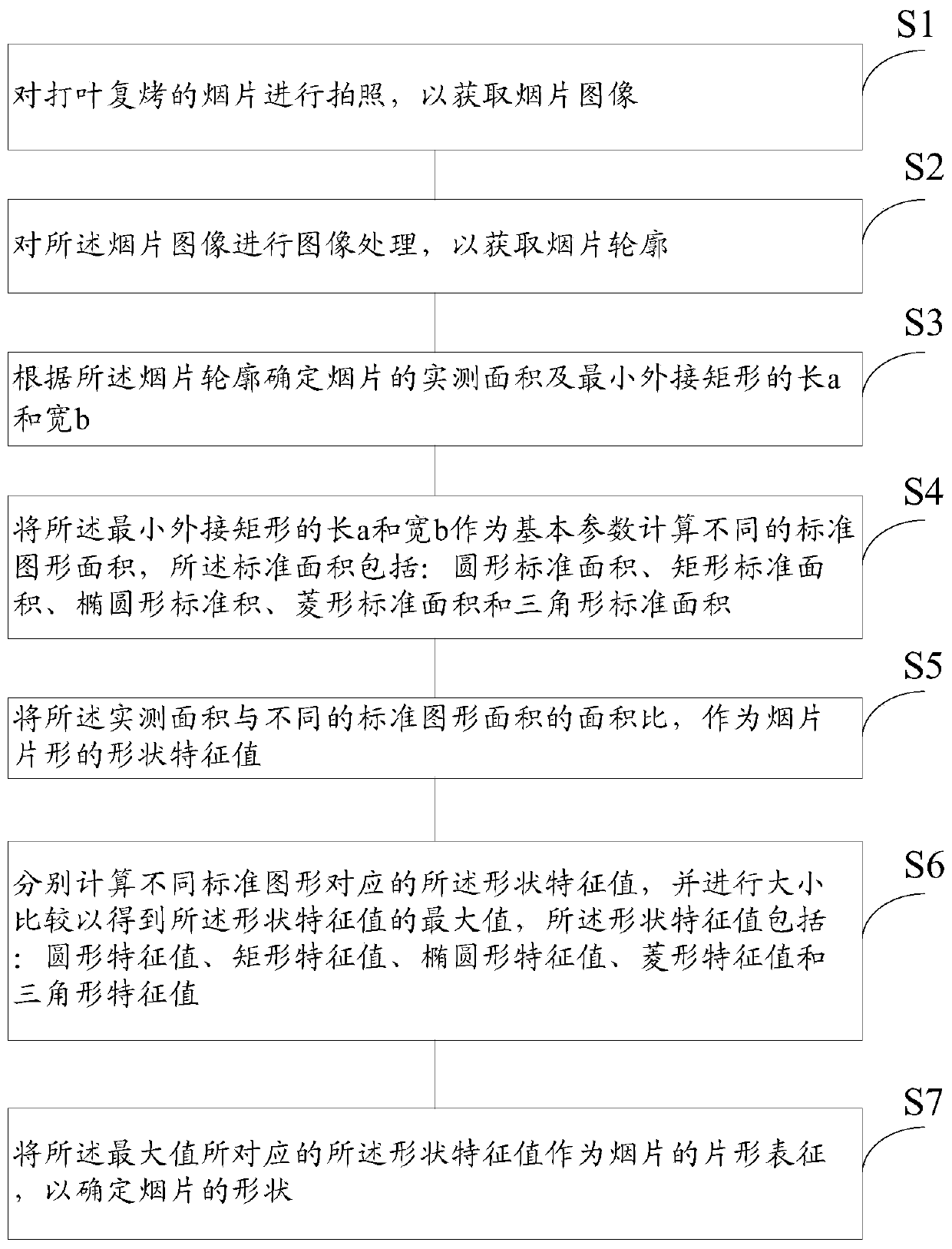

[0044] In order to enable those skilled in the art to better understand the solutions of the embodiments of the present invention, the embodiments of the present invention will be further described in detail below in conjunction with the drawings and implementations.

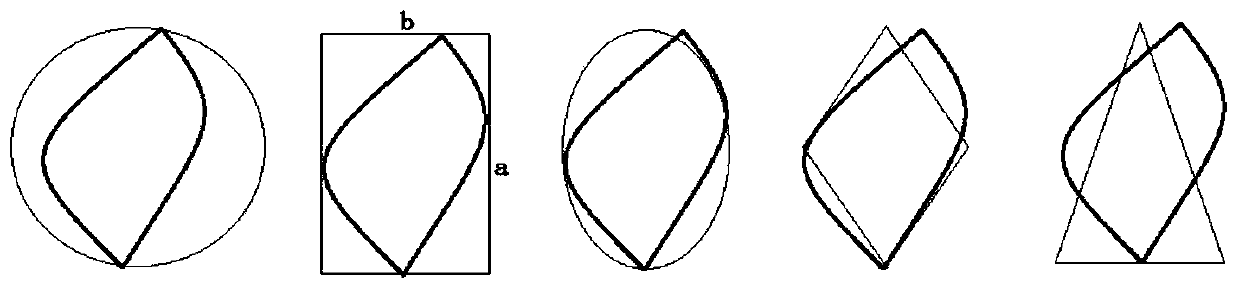

[0045] Since the shape of the tobacco sheet directly affects the quality of the shreds during threshing and redrying, the current characterization of the shape of the tobacco sheet is inaccurate. The invention provides a method and system for characterizing the sheet shape of threshing-leaf red-cured tobacco sheet. The image of the sheet is obtained by taking pictures of the sheet, and the measured area and the length and width of the minimum circumscribed rectangle are obtained according to the image of the tobacco sheet. The length and width of different standard graphic areas are calculated, and the area ratio of the measured area to the standard graphic area is used as the shape representation of the smoke sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com